Crystal pulling furnace with turnover device

A technology of turning device and crystal pulling furnace, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of poor crystal pulling effect, and achieve the effect of energy saving and good crystal pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

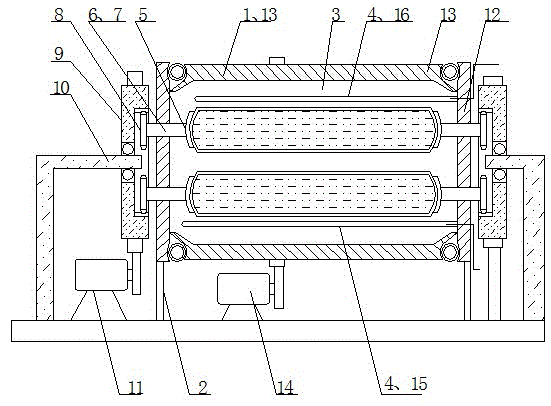

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] like figure 1 As shown, the crystal pulling furnace with a turning device includes a furnace body 1, the furnace body is installed on a shelf 2, and the furnace body 1 has a furnace chamber 3 inside, and a heating device 4 and a plurality of groups of clamping and pulling transistors are arranged in the furnace chamber. Clamp 5, the heating device can heat the pulling transistor, which is characterized by:

[0021] The two ends of the furnace body have a plurality of sets of shaft holes 6 corresponding to the clips, the first shaft 7 is installed behind the clips, the first shaft passes through the shaft hole, and there is a pinion 8 outside the first shaft;

[0022] There is a runner 9 outside the end of the body of heater, and the runner 9 is installed on the frame through the rotating shaft 10, and the runner is connected to the first power unit 11. There is a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com