Crystal pulling tube with metal wires and crystal pulling furnace

A metal wire and crystal pulling furnace technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of slow crystal pulling speed and poor crystal pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

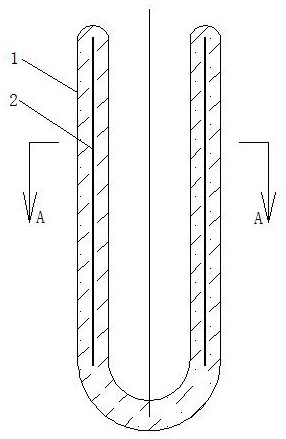

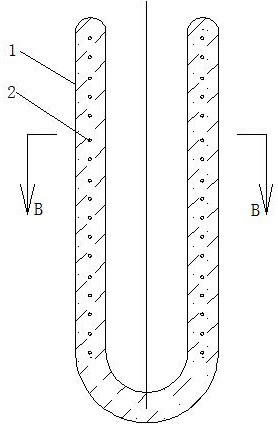

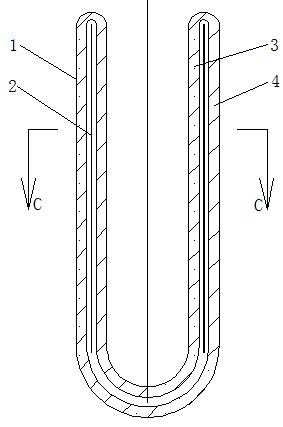

[0029] Such as Figure 1-8 As shown, a pull transistor with metal wires includes a pull transistor body 1 , the pull transistor body has a side wall, and the feature is: the metal wire 2 is inside the side wall.

[0030] When the crystal pulling tube is used, as in the prior art, the raw material powder is placed in the crystal pulling tube and placed in the furnace chamber of the crystal pulling furnace for crystal pulling, and the furnace chamber is in an environment with a magnetic field and an electric field , the raw material is melted, because the metal wire is arranged in the middle of the raw material, it can promote the arrangement of the crystal grain molecules, and achieve the effect of fast crystal pulling speed. The metal wire is also beneficial to wake up more raw material molecules to rearrange, so as to achieve The purpose of better effect can achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com