Waste selvage material saving method for rapier loom

A rapier loom, material-saving technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as reducing production costs, production of defective fabrics, failures, etc., to reduce costs, save energy, and reduce waste. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

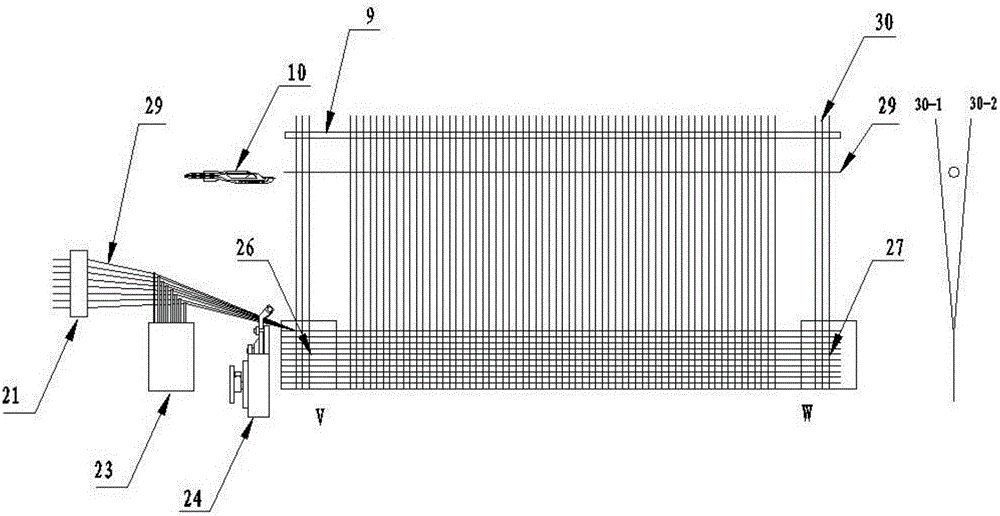

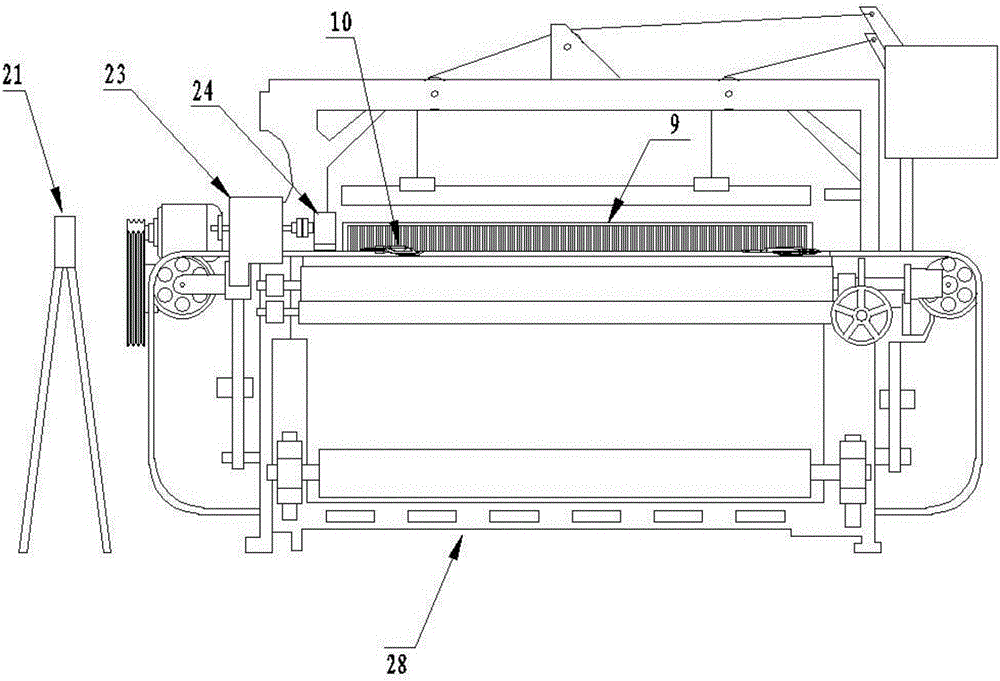

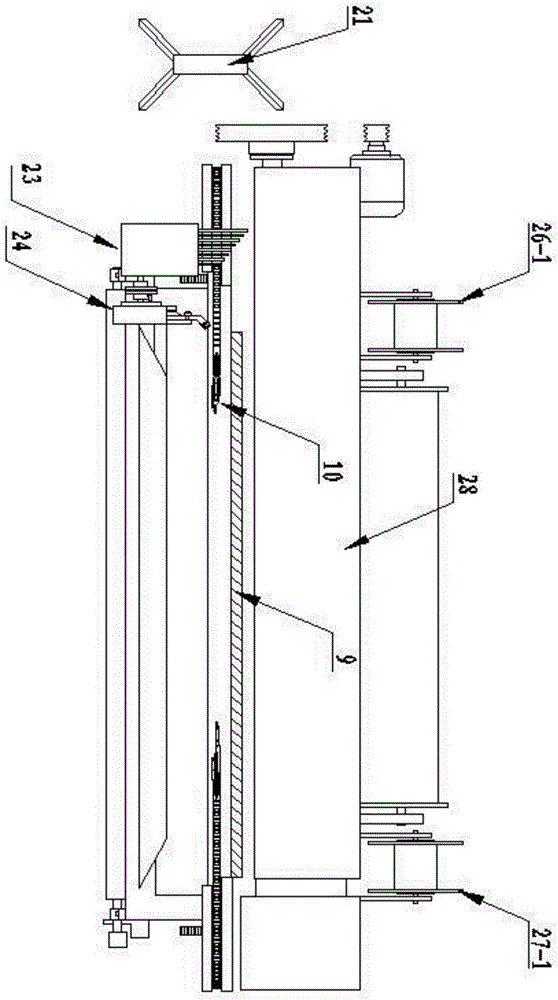

[0092] Such as Figure 1 to Figure 4 , is the structural diagram of the current rapier loom, including the weft passing mechanism, the weft selection shuttle box, and the common non-energy-saving weft thread scissors box. Due to structural limitations, there are the above-mentioned problems.

[0093] Such as Figure 5-8 As shown, the rapier loom of the present invention is provided with an energy-saving device, the energy-saving device is matched with the weft thread shuttle, the energy-saving device includes 8 weft clamping mechanisms corresponding to the weft thread shuttle, and the energy-saving device also includes a weft thread scissors , The energy-saving device is also provided with an auxiliary weft clamping mechanism for transferring the weft clamping task between the weft clamping mechanisms.

[0094] Such as Figure 9-10 As shown, the energy-saving device is controlled by mechanical control, such as Figure 11-12 As shown, the energy-saving device is controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com