Humidity detection and moisturizing control method and system for large-volume concrete

A technology for mass concrete and humidity detection, applied in humidity control, control/regulation system, non-electric variable control, etc., can solve the problems of water replenishment timing and poor control accuracy of water replenishment, and achieve accurate water replenishment timing, good effect and precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: A large-volume concrete humidity detection and moisture control method. A humidity sensor is arranged on the surface of the constructed concrete, and the humidity sensor is used to detect whether the humidity of the surface area of the constructed concrete meets the humidity standard range. If it is less than the lower limit of the humidity standard range When the value is d1, the humidity sensor sends a water replenishment signal to the controller of the spraying system, and the controller controls the spraying system to spray water at a fixed time or quantity; and, a delayer A is set, and the delayer A is in the delay range T A Inside, the controller of the spraying system does not accept any signal from the humidity sensor; the spraying system stops spraying water after meeting the timing or quantitative water spraying requirements; the delayer A is in the delay range T A In addition, when the humidity sensor detects that the humidity in the surface ar...

Embodiment 2

[0023] Embodiment 2: a kind of mass concrete humidity, temperature The detection and moisture control method, on the basis of Embodiment 1, is equipped with a temperature sensor together with the humidity sensor, and a cooling pipe is arranged in the mass concrete. When the value of the temperature sensor rises to a critical value, the cooling system drives cooling water into the cooling pipe. Circulate in the tube and cool down.

Embodiment 3

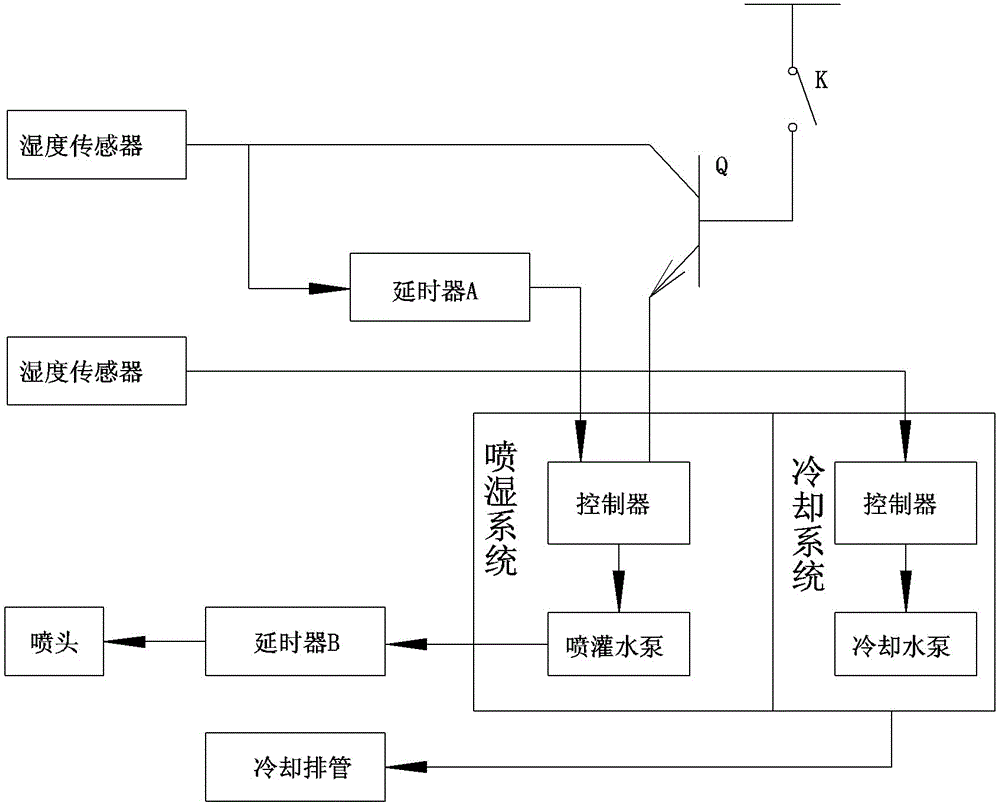

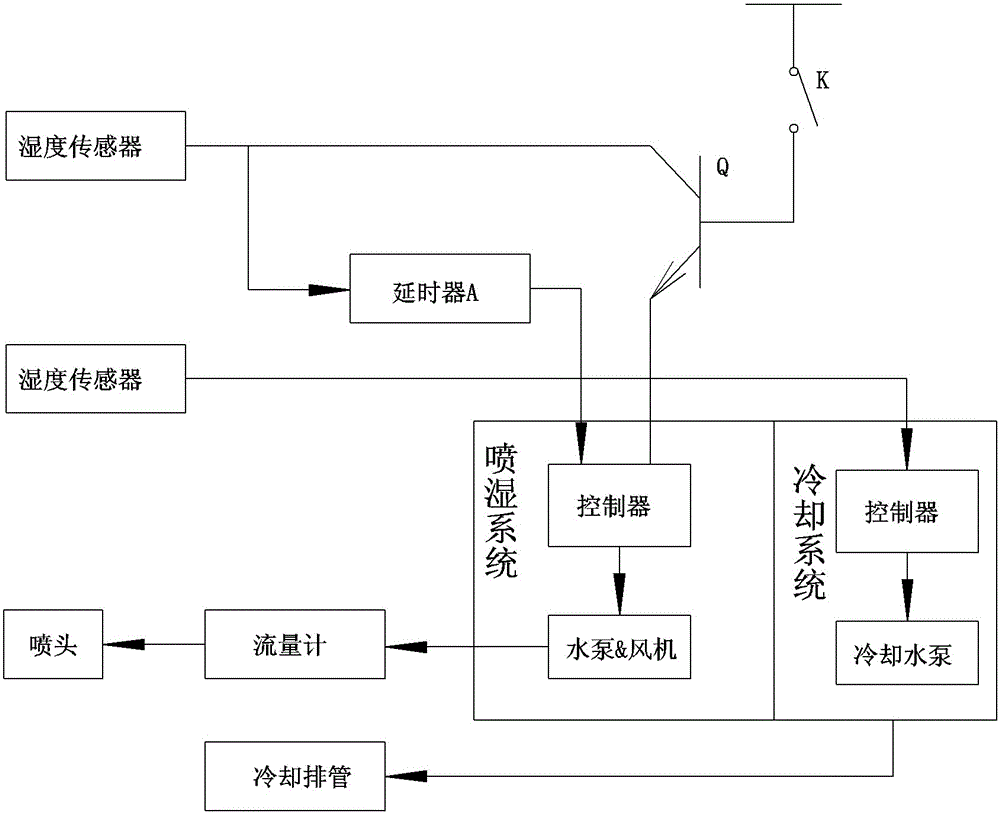

[0024] Embodiment 3: see figure 1 , a large-volume concrete humidity detection and moisture control system. A humidity sensor is arranged on the surface of the constructed concrete. The humidity sensor is connected to the signal input terminal of the controller of the spraying system through the delayer A, and the output terminal of the controller of the spraying system is connected to the signal input terminal of the spraying system. The water pump is connected, and the delay device B is set on the water pump at the same time.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap