Control tower pile used for manufacturing high-strength cemented soil mixing pile

A high-strength cement and mixing pile technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems that waste slag cannot be used well, pullout resistance, and strength need to be further improved, so as to improve strength, The effect of improving peripheral strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

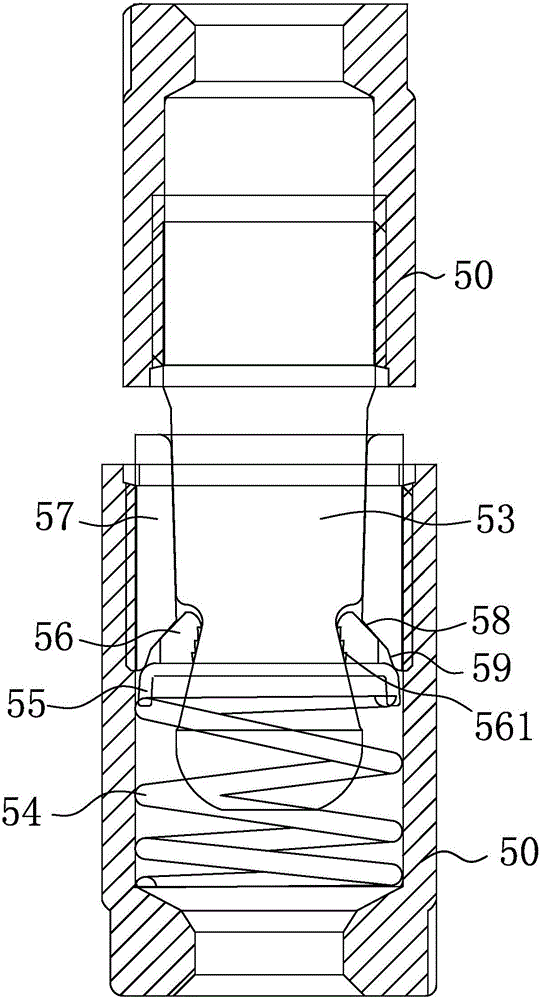

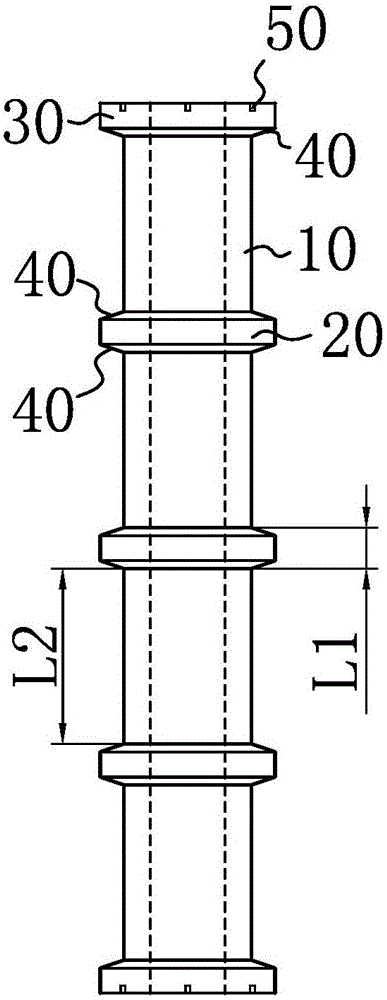

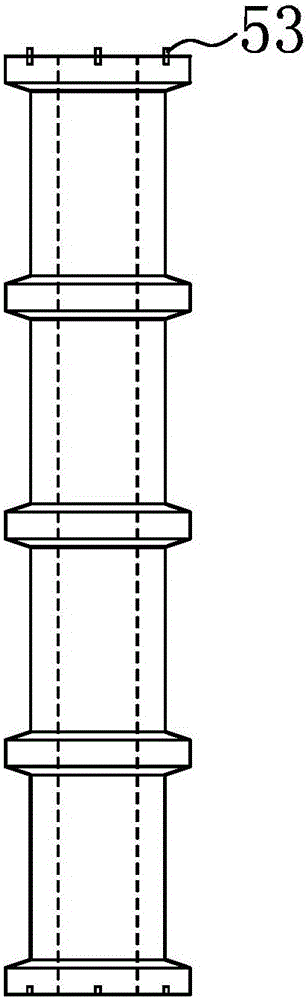

[0031] like figure 1 Shown, a kind of tower pile that is used to make high-strength cement-soil mixing pile, comprises pile body 10, can be provided with steel reinforcement ring or the vertical and transverse reinforcement ring that carbon fiber is made in pile body 10, is used to improve pile body 10 strength, the pile body 10 is provided with at least one tower 20 protruding outward along the radial direction of the pile body 10 , and the cross-sectional area of the tower 20 is larger than that of the pile body 10 .

[0032] Tower 20 has several and is evenly arranged along the axial direction of pile body 10, is respectively provided with a connection platform 30 at the two ends of pile body 10, and the cross-sectional area of described connection platform 30 is greater than the cross-sectional area of pile body 10, and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com