A kind of mixed gas oven burner device

A mixed gas and oven technology, which is applied in the direction of burners, burners, combustion methods, etc., can solve the problems of wasting resources, increasing cost investment, etc., and achieve the effects of reducing gas source costs, strong practicability, and good combustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

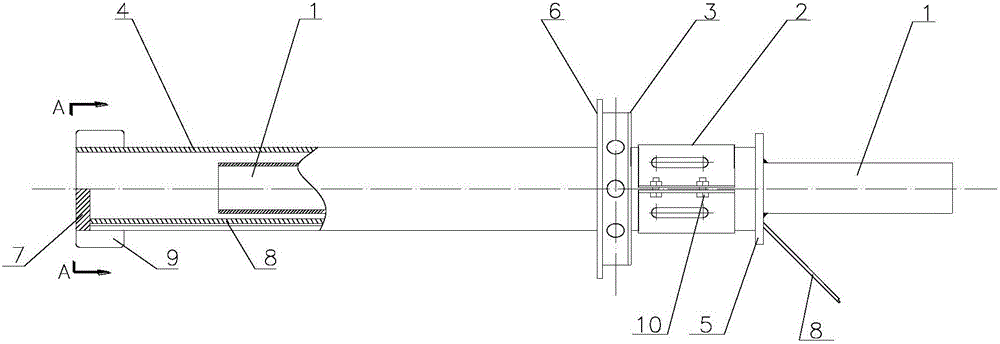

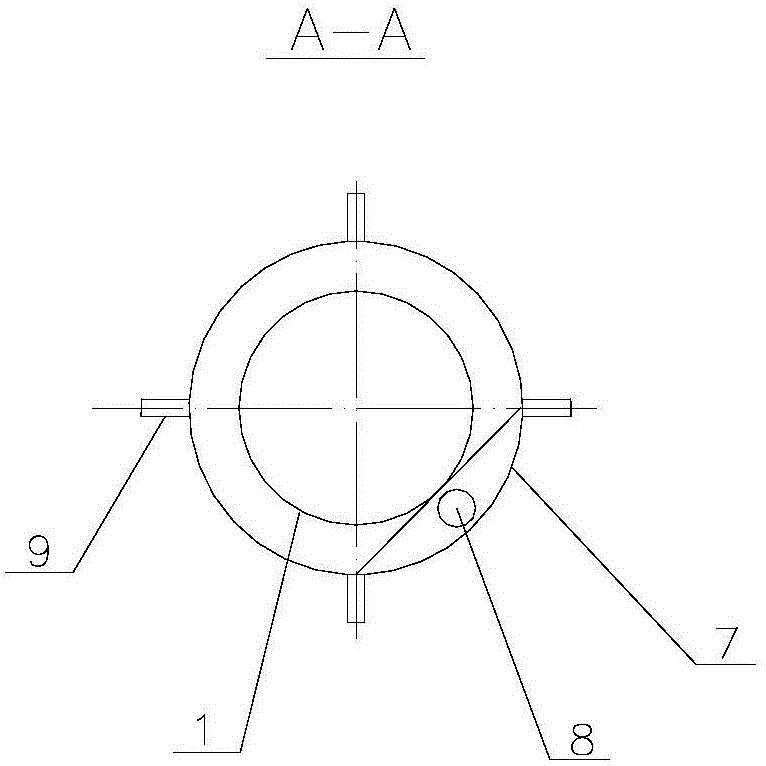

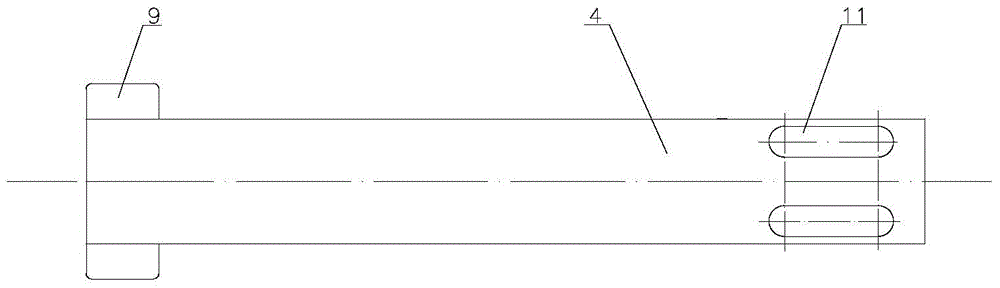

[0025] see picture 1- Figure 8 , is a structural schematic diagram of the present invention, a burner device for a mixed gas oven in the present invention, comprising a burner inner tube 1, a burner jacket 4, a primary air volume regulator 2, a secondary air volume regulator 6 and a natural gas burner 8, One end of the burner inner tube 1 extends into and is fixed in the burner jacket 4, and the other end is connected with the blast furnace gas pipeline; one end of the natural gas burner 8 extends and is fixed between the burner jacket 4 and the burner inner tube 1 The other end is connected to the natural gas pipeline in the annular gap; the burner jacket 4 is provided with a primary air volume regulator 2 and a secondary air volume regulator 6, and the secondary air volume regulator 6 is located at the front end of the primary air volume regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com