Oil level gauge and speed reducer comprising same

An oil level gauge and reducer technology, which is used in instruments, liquid level indicators, engine lubrication, etc., can solve the problems of easy scalding of oil to operators, waste of resources, environment, and personal injury, so as to reduce oil waste, Improve work efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

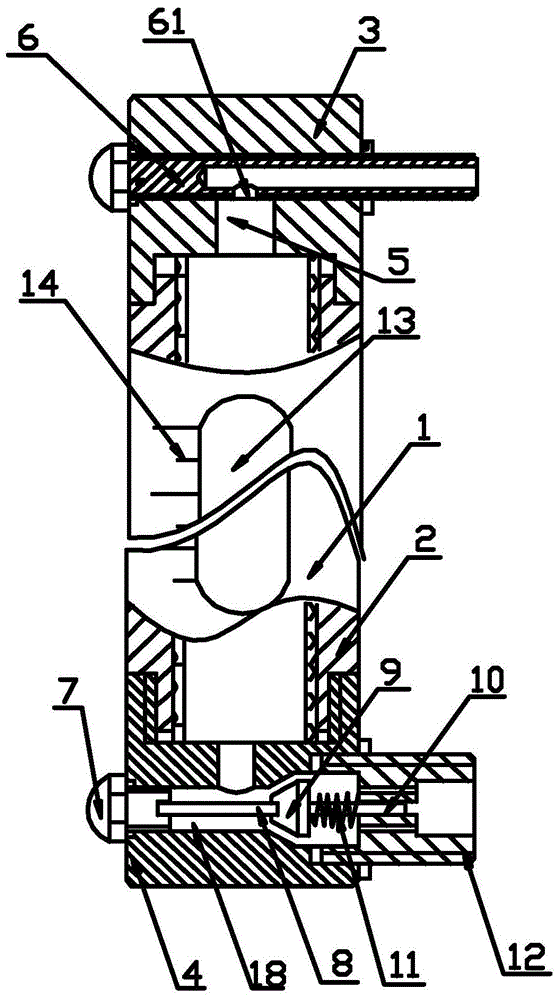

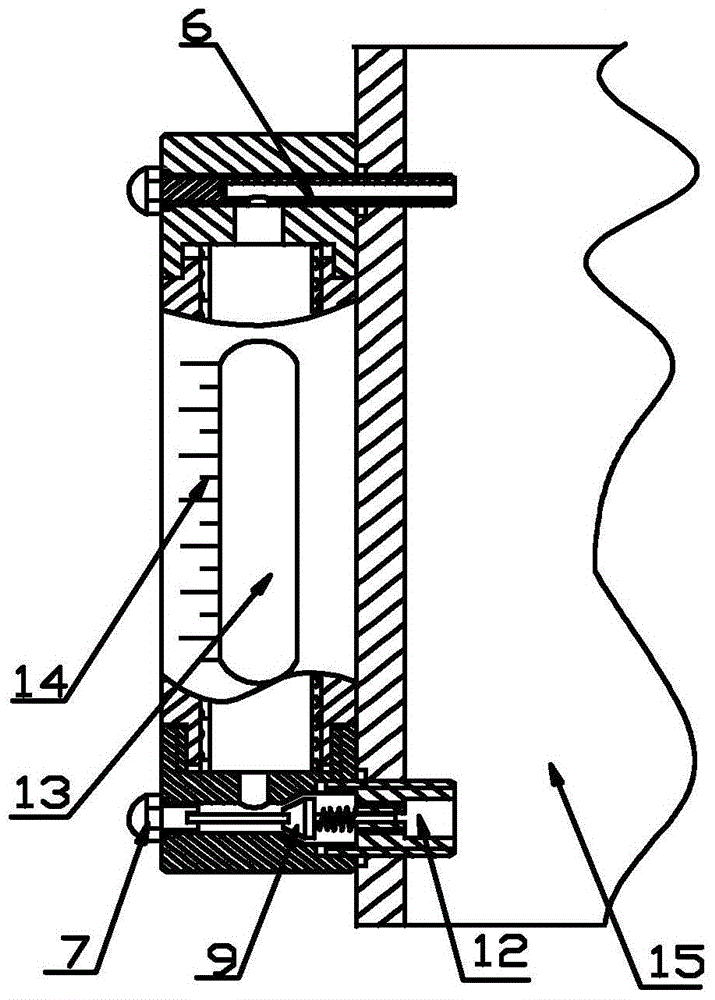

[0028] Such as figure 1 As shown, an oil level gauge includes a main body 1, a top seat 3 located above the main body 1, and a base 4 located below the main body 1, the interior of the top seat 3 and the base 4 are respectively provided with through holes communicating with the main body 1 15. A protective cover 2 is provided on the periphery of the main body 1 to protect the integrity of the main body 1. At least one window 13 is provided on the protective cover 2, and a scale line 14 is provided on the edge of the window 13. It is convenient to observe the oil quantity and quality of the oil in the main body 1 .

[0029] The inside of the base 4 is provided with a passage 18, and the passage 18 communicates with the through hole one 5. One end of the passage 18 is provided with a plug 7, and the other end is provided with a fastener two 12. The passage 18 The middle part is also provided with a non-return device, the non-return device includes a guide rod 10 and an oil plug...

Embodiment 2

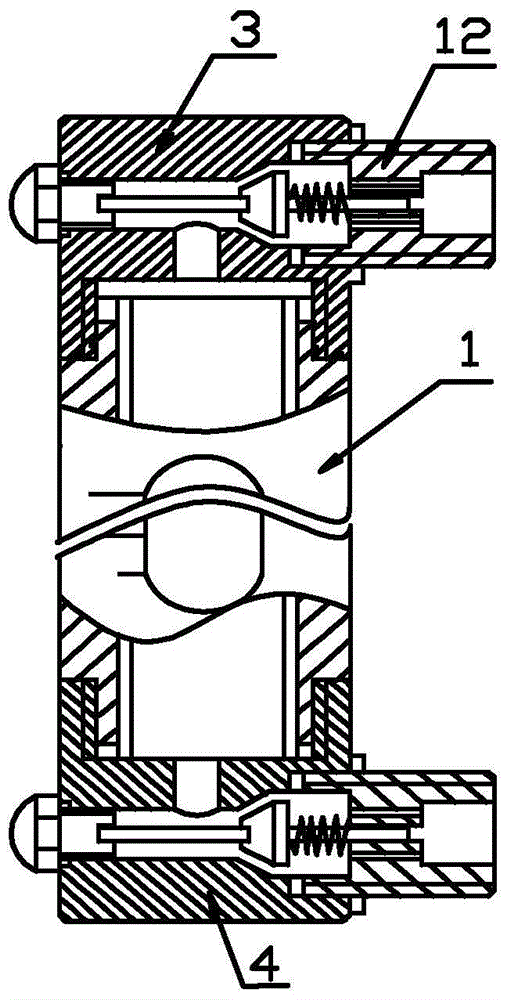

[0032] Such as figure 1 , Figure 4 As shown, the second fastener 12 is provided with a second through hole 16 and a third through hole 17 connected to the guide rod 10, and the diameter of the second through hole 16 matches the diameter of the guide rod 10, and the guide rod The diameter of the second through hole 10 is slightly smaller than the diameter of the second through hole 16, so that the second through hole 16 plays a role in fixing the guide rod 10, and the third through hole 17 is arranged on the periphery of the second through hole 16 to facilitate oil in and out. bit meter.

[0033] The oil plug 9 and the screw plug 7 are respectively located on both sides of the through hole 15. When the oil level gauge is maintained and replaced, only the screw plug 7 needs to be removed to separate the ejector rod 8 from the oil plug 9. , the oil plug 9 moves in the channel 18 of the conical structure under the elastic force of the elastic member 11, the oil plug 9 is set to...

Embodiment 3

[0036] Such as image 3 As shown, the internal structure of the top seat 3 is the same as that of the base 4. In special cases, excessive lubricating oil needs to be added to the interior of the reducer 15, causing the oil level in the oil level gauge to exceed its upper limit. Both the upper and lower parts of the oil level gauge are provided with non-return devices. When the oil level gauge is repaired and replaced, oil leakage can be prevented from the upper and lower parts of the oil level gauge. The position meter is connected by two fasteners 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com