Multistage belt conveyer coordination control system based on internet of things and method

A belt conveyor, coordinated control technology, applied in the field of sensing and measurement and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

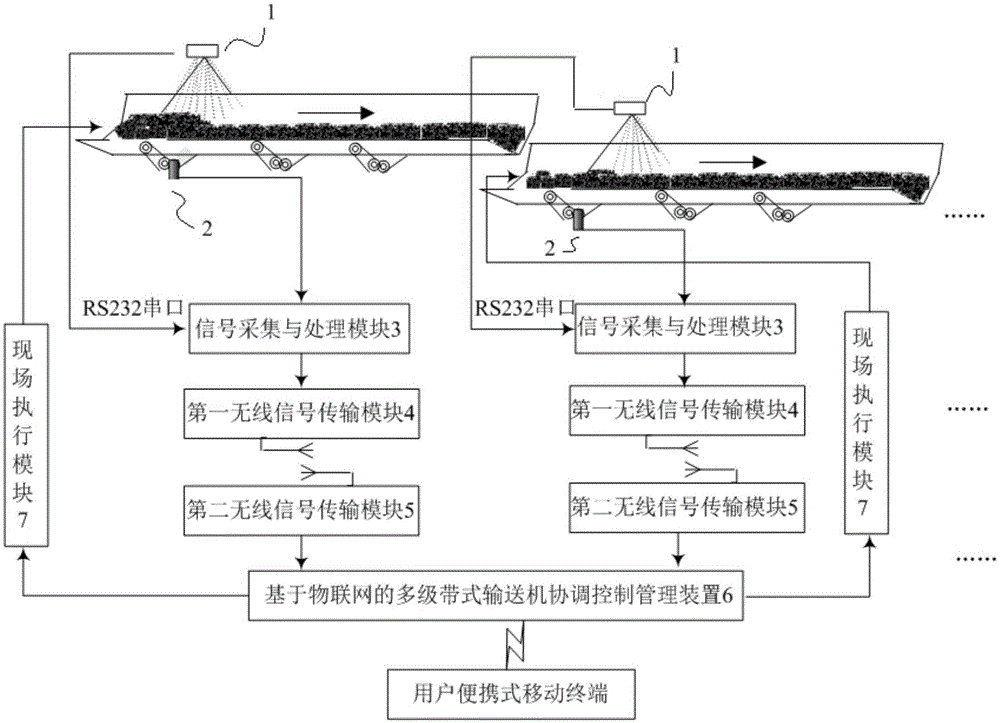

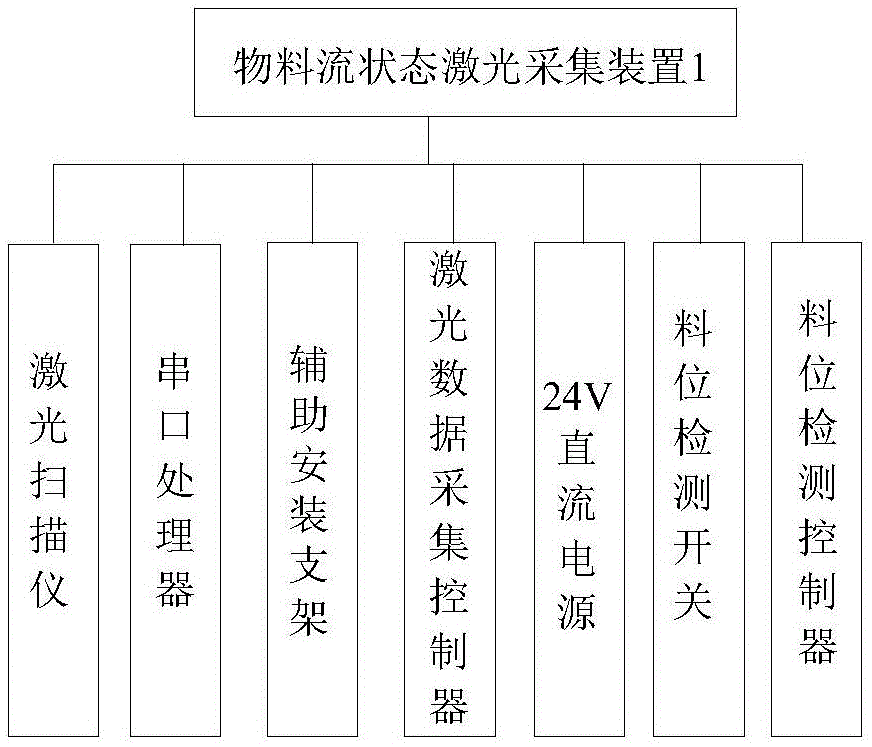

[0076] A coordinated control system for multi-stage belt conveyors based on the Internet of Things, including a material flow state laser acquisition device 1 for monitoring the instantaneous flow of materials in a multi-stage material transfer device, and also includes

[0077] Photoelectric encoder 2, used to monitor the transmission belt speed of the material transmission device;

[0078] The signal acquisition and processing module 3 is used to receive the belt conveyor speed signal sent by the photoelectric encoder 2 and the instantaneous flow rate of the material collected by the material flow state laser acquisition device 1, and to transmit the belt conveyor speed signal and the instantaneous flow rate of the material transmitted to the first wireless signal transmission module 4;

[0079] The first wireless signal transmission module 4 is used to send the speed signal of the belt conveyor and the instantaneous flow rate of the material to the second wireless signal tr...

Embodiment 2

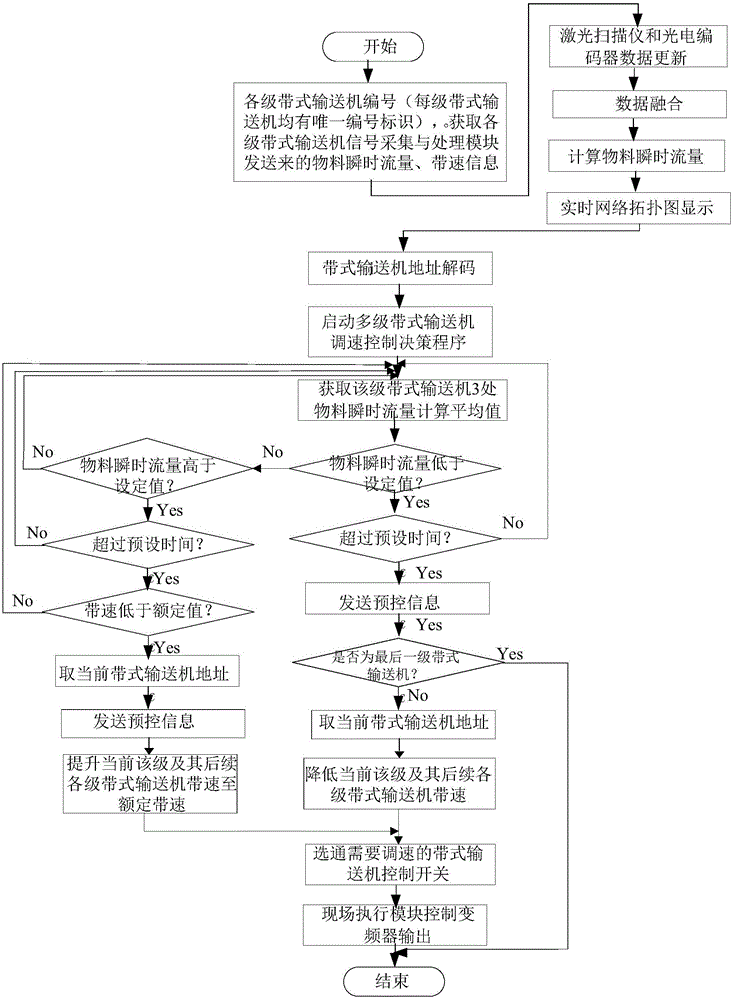

[0098] A method for coordinated control of a multi-stage belt conveyor based on the Internet of Things, comprising the following steps:

[0099] Step 1, the signal acquisition and processing module 3 transmits the collected current-stage belt conveyor material instantaneous flow signal and the collected current-stage belt conveyor belt speed signal through the first wireless signal transmission module 4 and the second wireless signal transmission The module 5 is transmitted to the multi-stage belt conveyor coordination control management device 6 based on the Internet of Things;

[0100] Step 2. The multi-stage belt conveyor coordination control management device 6 based on the Internet of Things obtains the instantaneous flow rate value of the material and the belt speed value of the belt conveyor at the current stage according to the instantaneous flow rate signal of the material and the belt speed signal of the belt conveyor;

[0101] Step 3. Instantaneous material flow rat...

Embodiment 3

[0151] A method for coordinated control of a multi-stage belt conveyor based on the Internet of Things, comprising the following steps:

[0152] Step 1, the signal acquisition and processing module 3 transmits the collected current-stage belt conveyor material instantaneous flow signal and the collected current-stage belt conveyor belt speed signal through the first wireless signal transmission module 4 and the second wireless signal transmission The module 5 is transmitted to the multi-stage belt conveyor coordination control management device 6 based on the Internet of Things;

[0153] Step 2. The multi-stage belt conveyor coordination control management device 6 based on the Internet of Things obtains the instantaneous flow rate value of the material and the belt speed value of the belt conveyor at the current stage according to the instantaneous flow rate signal of the material and the belt speed signal of the belt conveyor;

[0154] Step 3. Find the average value Q of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com