External-hanging type touch control display device and assembling method of external-hanging type touch control display device

A touch display device, plug-in technology, applied in optics, instruments, electrical digital data processing, etc., can solve the problems of long assembly time, difficult assembly, cumbersome assembly steps, etc., saving time and production cost, and simplifying assembly steps. , The effect of saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

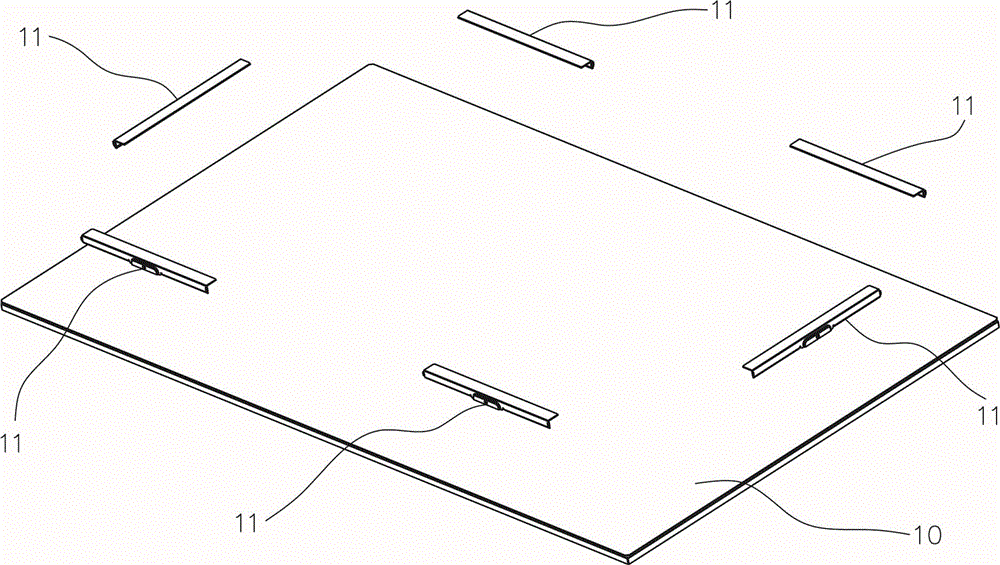

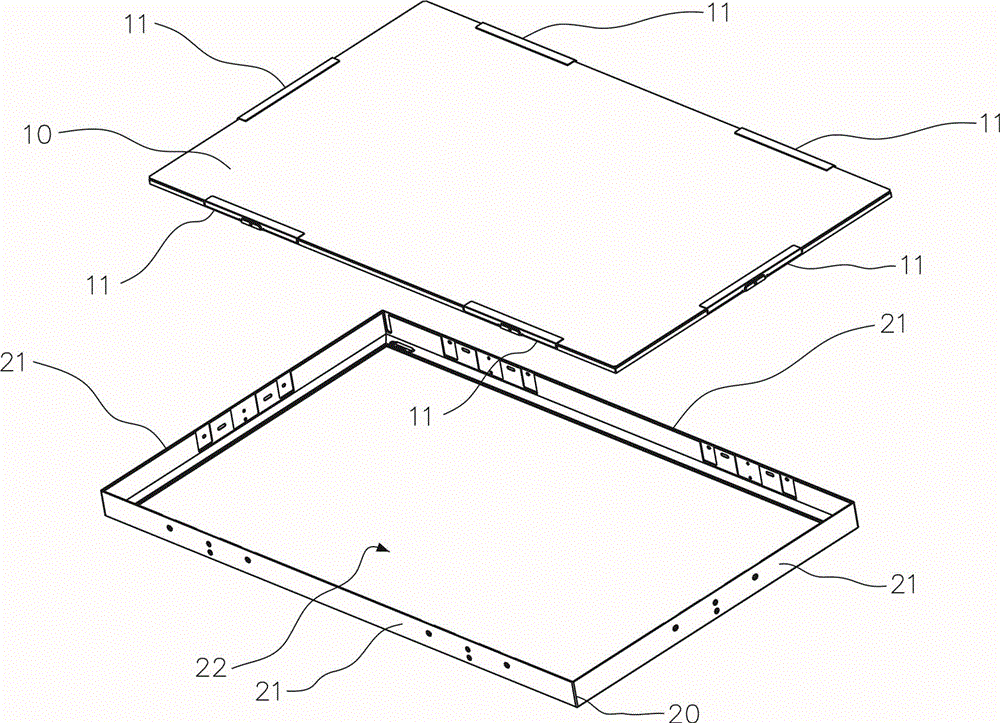

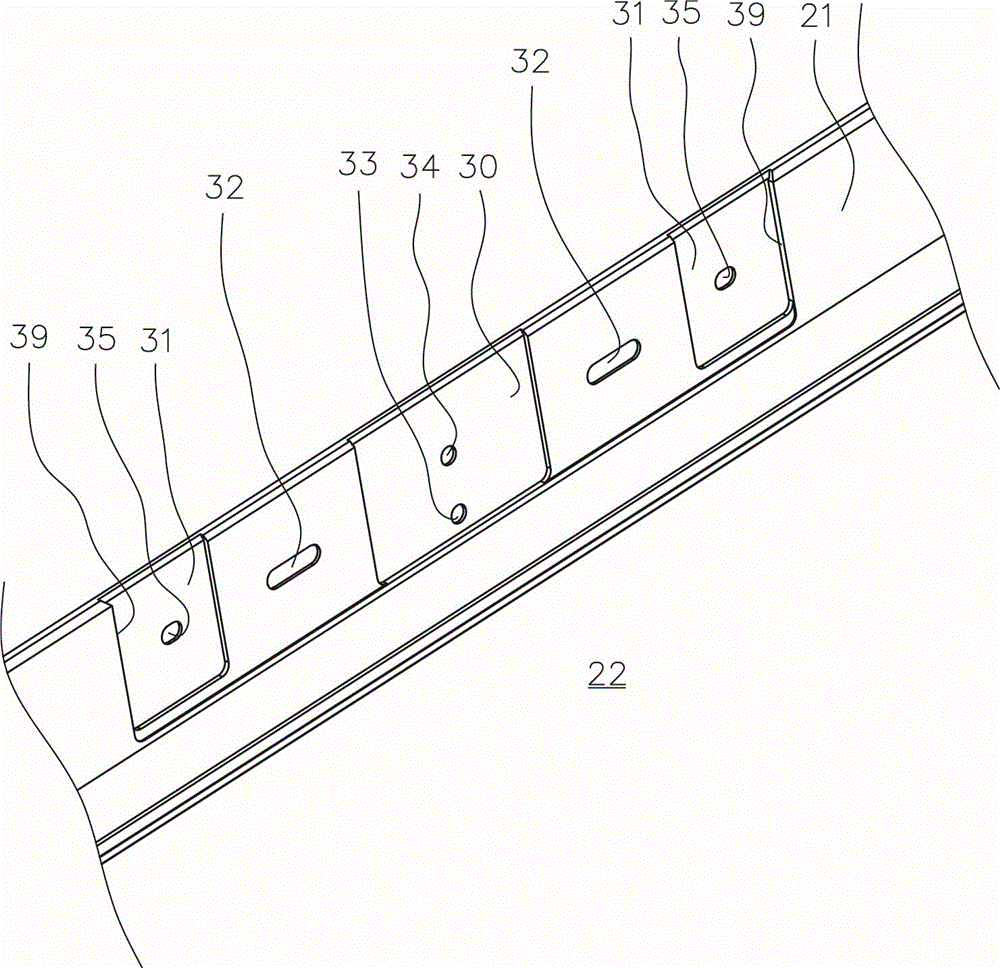

[0050] Please refer to figure 1 , figure 1 Shown is the first step of assembling the external touch display device. The external touch display device includes a touch module 10 and a first positioning member 11. The assembling step is first to set the first positioning member 11 at a predetermined position on the touch module 10. In this embodiment, the touch module 10 A mark can be set on the predetermined position of the, and during assembly, the first positioning member 11 is glued to the touch module 10 where the mark is provided. In addition, the cross section of the first positioning member 11 has an L-shape. Therefore, after the first positioning member 11 is glued to the touch module 10, the first positioning member 11 will contact the side and the back of the touch module 10 at the same time. Although in the exemplary embodiment shown in the figure, the number of the first positioning member 11 is plural and distributed on the four sides of the touch module 10, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com