Organic molecule capsulated metal nanoparticles as well as preparation method and application thereof

A technology of nano metal particles and organic molecules, applied in the fields of nanotechnology, nanotechnology, nanotechnology for information processing, can solve the problems of reducing the photoelectric conversion efficiency and service life of the device, unreasonable cost structure, etc., to improve the photoelectricity. /Effect of electro-optical conversion efficiency, excellent organic solubility, production cost and time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

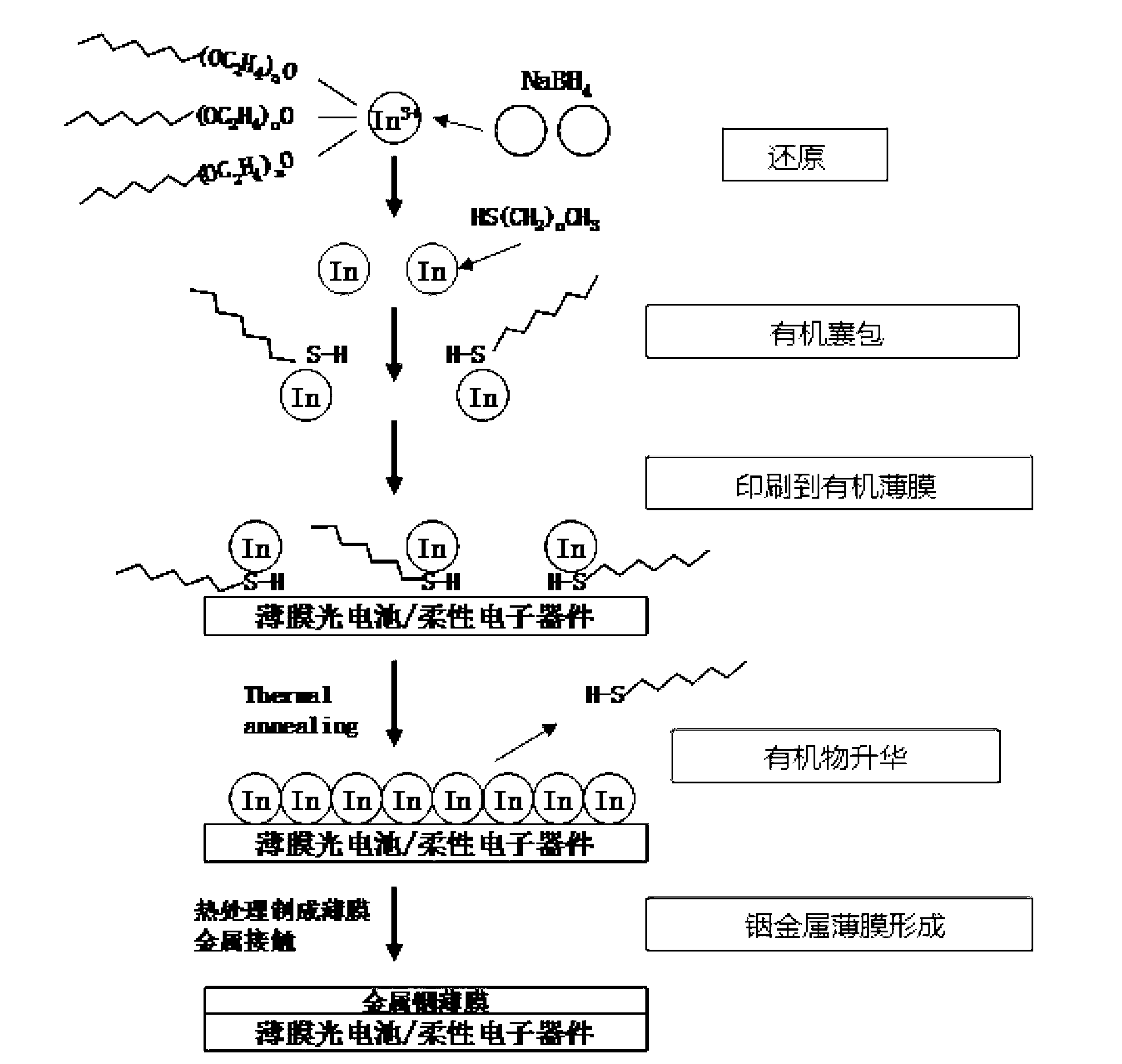

[0025] In order to prepare nano-metals compatible with organic polymer interfaces, this application provides nano-metal indium particles encapsulated by organic molecules (alkanethiols). An alkylthiol can be used: hexanethiol ( Hexanethiol). The size of nano-metal indium particles can be determined by organic alkylthiol and in 3+ to control the molar ratio. The detailed process of this synthesis process method sees figure 1 shown. Concrete process steps are as follows:

[0026] a. First, 2.0 grams of indium chloride (InCl 3 ) was dissolved in 5.0ml of 0.06m HCl solution, and then dissolved in 10.0ml of 20%wt hexane (Hexane) solution, while using 0.4ml of tetrapolyethylene glycol monolauryl ether (C 12 E. 4 : Tetraethylene glycol monododecyl ether) is added into the solution as a non-ionic surfactant to form a solution containing water molecules, surfactants, organic solvents and In 3+ microemulsion molecular clusters.

[0027] b. Add a quantitative amount of hexanethiol...

Embodiment 2

[0031]The preparation method of nano-metal indium particles encapsulated by organic molecules, first dissolves indium chloride into hydrochloric acid, wherein the mass ratio of HCl to indium chloride is 175:1, and then adds it into the hexane solution, and the indium chloride and hexane The mass ratio of alkanes is 4: 1, uses tetrapolyethylene glycol monolauryl ether to add in the solution simultaneously as nonionic surfactant, and the mass ratio of indium chloride and tetrapolyethylene glycol monolauryl ether is 4: 1, with This formation contains water molecules, surfactants, organic solvents and In 3+ The microemulsion micelles molecular group; Quantitative hexanethiol is added in the above-mentioned solution, hexanethiol: in 3+ The molar ratio is 4:1; Metal indium is reduced from the above-mentioned organic solvent using excessive reducing agent sodium borohydride, sodium borohydride: in 3+ The molar ratio is 1.5:1, forming nano-sized metal indium particles encapsulated by...

Embodiment 3

[0034] The preparation method of nano-metal indium particles encapsulated by organic molecules, first dissolves indium chloride into hydrochloric acid, wherein the mass ratio of HCl to indium chloride is 200:1, and then adds it into the hexane solution, and dissolves indium chloride and hexane The mass ratio of alkanes is 2:5, uses tetrapolyethylene glycol monolauryl ether to add in the solution simultaneously as nonionic surfactant, and the mass ratio of indium chloride and tetrapolyethylene glycol monolauryl ether is 5:1, with This formation contains water molecules, surfactants, organic solvents and In 3+ The microemulsion micelles molecular group; Quantitative hexanethiol is added in the above-mentioned solution, hexanethiol: in 3+ The molar ratio is 1:8; Metal indium is reduced from the above-mentioned organic solvent using excessive reducing agent sodium borohydride, sodium borohydride: in 3+ The molar ratio is 1:1, forming nano-sized metal indium particles encapsulated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com