Brazing diamond grinding aids abrasion resistance evaluation device and evaluation method

A technology of wear resistance and evaluation device, applied in the direction of testing wear resistance, special data processing applications, instruments, etc., can solve the problems of poor thermal stability of diamond, easy damage and deterioration, thermal damage of diamond abrasives, etc., to save production costs and time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, introduce the content of the present invention in detail.

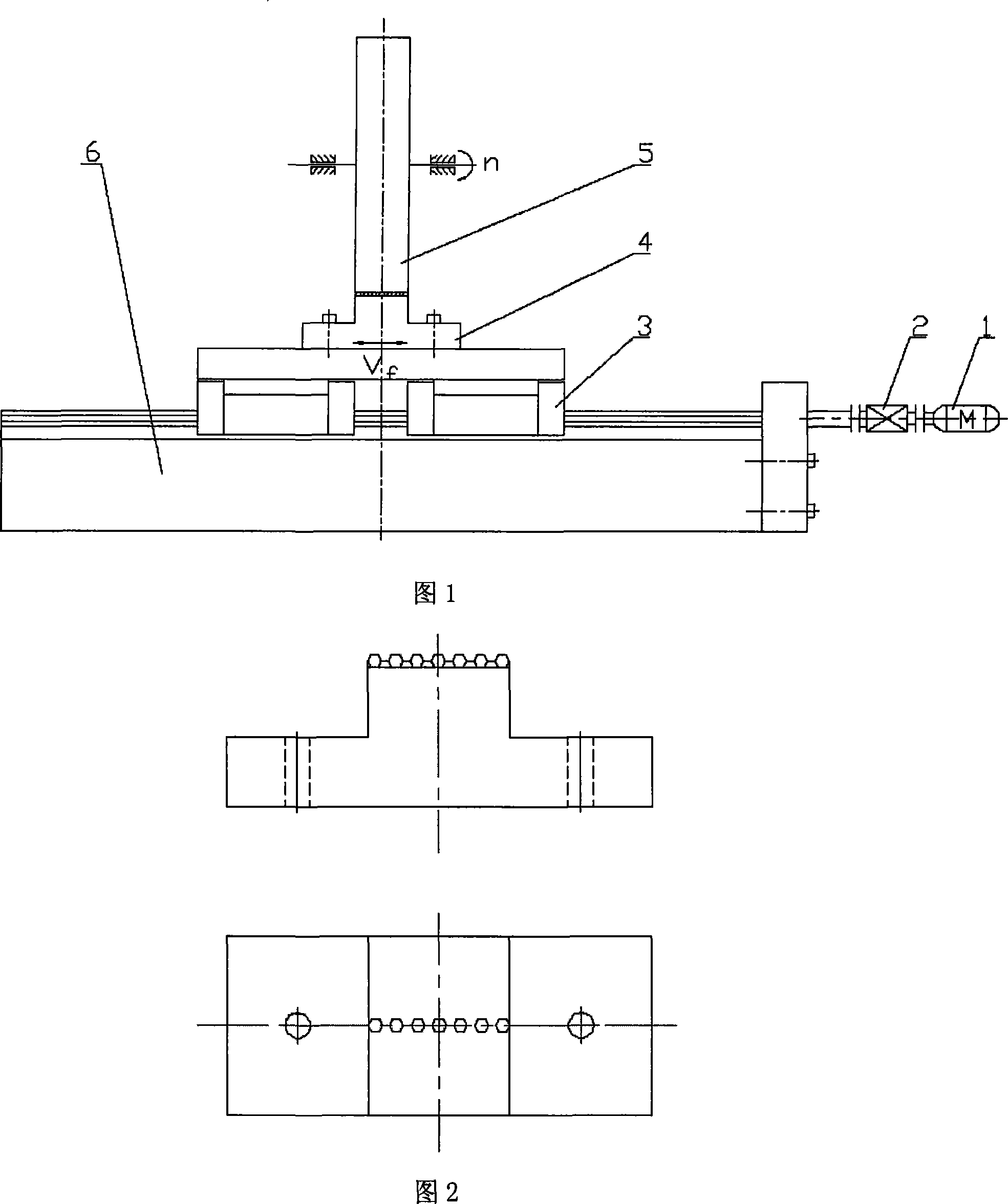

[0028] Fig. 1 is the structure schematic diagram of the evaluation device of the present invention, and this device is made up of stepper motor 1, speed reducer 2, single-coordinate table 3, diamond abrasive segment 4, workpiece 5 and surface grinder 6 with horizontal axis and rectangular table.

[0029] The diamond abrasive segment 4 is connected to the single-coordinate table 3 through bolts; the single-coordinate table 3 is connected to the power part through a coupling, and the power part is composed of a stepping motor 1 and a reducer 2; the workpiece 5 is installed on the grinding wheel spindle On the machine, its power part is provided by the grinder power system.

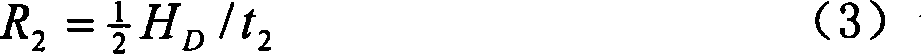

[0030] Fig. 2 is a schematic diagram of a diamond abrasive segment, and the diamond abrasive grains are arranged in a row at the center of the top of the segment. In order to facilitate the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com