Piston assembly realizing adjustable diameter through grease injection

A kind of piston and grease injection technology, which is applied to the parts of pumping devices for elastic fluids, variable displacement pump parts, machines/engines, etc. It can solve the problems of accelerated wear parts, pressure piercing, difficult sealing effect , to achieve the effect of saving production cost and time, prolonging service life and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

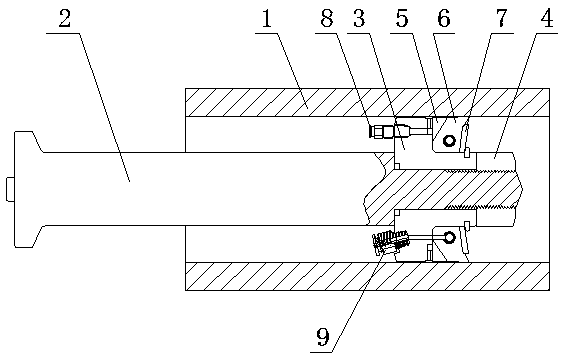

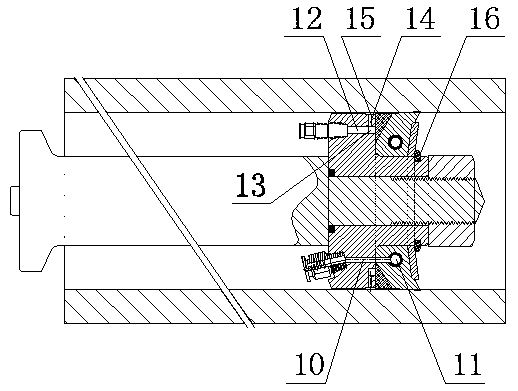

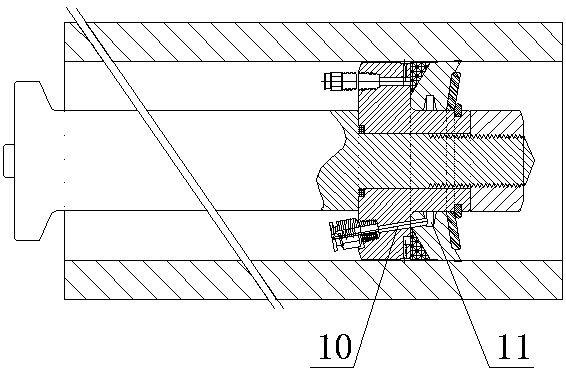

[0015] The grease injection adjustable diameter piston assembly consists of mud pump pull rod 2, piston core 3, lock nut 4, nylon support ring 5, piston rubber 6, rubber compression ring 7, water injection quick joint 8, high pressure cement injection joint 9 Composition, one end of the mud pump pull rod 2 is equipped with a piston iron core 3, the piston iron core 3 is fastened by a lock nut 4, the piston iron core 3 is a stepped cylindrical structure, and the small diameter end of the piston iron core 3 is equipped with Piston rubber 6, the bottom of piston rubber 6 is equipped with nylon support ring 5, and the front edge of piston rubber 6 is equipped with rubber compression ring 7, and rubber compression ring 7 is clamped by elastic circlip 16; Described piston rubber 6 and The joint surface of the inner wall of the mud pump cylinder liner 1 is an inclined conical surface, and its axial section is in the shape of a trumpet. One side of the through hole at the large diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com