3528 full-color LED lamp bead support

An LED lamp bead, full-color technology, used in electrical components, circuits, semiconductor devices, etc., can solve the problems of insufficient second welding tension, single welding wire position, and the impact of ceramic nozzle life, to improve stability and reliability, The effect of increasing the area of the welding line and avoiding the bad two solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

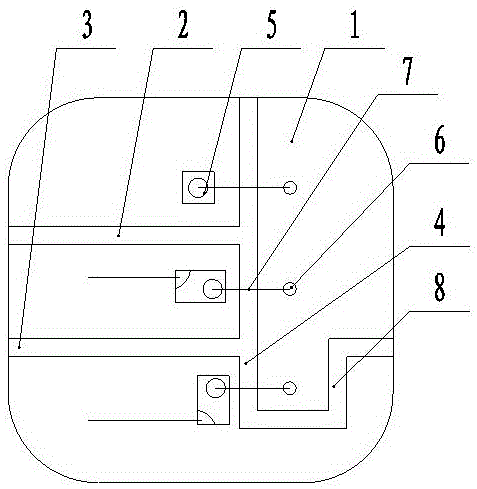

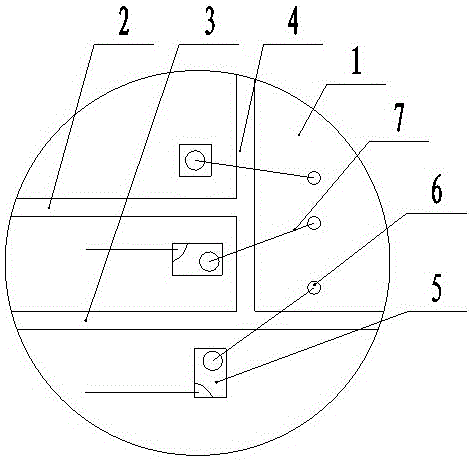

[0012] Such as figure 1 , figure 2 As shown, the 3528 full-color LED lamp bead bracket of the present invention includes a bracket cup 1, a first isolation strip 2, a second isolation strip 3 and a third isolation strip 4, the first isolation strip 2, the second isolation strip 3 and the third isolation strip 4 are all located on the end face of the bracket bowl cup 1, the first isolation strip 2 and the second isolation strip 3 are horizontally spaced apart, and the third isolation strip 4 is perpendicular to the first isolation strip 2 and the second isolation strip. The band 3 is set, and the first isolation band 2 and the second isolation band 3 divide the end surface of the bracket cup 1 on the side of the third isolation band 4 into three parts, each part is provided with a first welding contact 5, so The end longitudinal section of the bracket bowl 1 is elliptical, and the end surface of the bracket bowl 1 on the other side of the third isolation strip 4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com