Grouped battery pack

A battery pack and group technology, applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems of poor structural strength of battery packs, poor strength of battery packs, and high development costs, and achieve wide applicability, low production costs, and low production costs. The effect of protecting the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

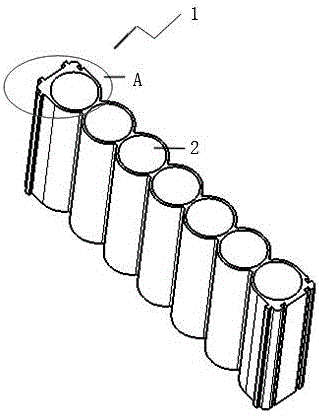

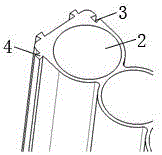

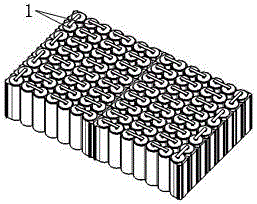

[0016] Such as Figures 1 to 4 As shown, the present invention is a grouped battery pack, the battery pack is formed by clamping several battery packs 1, the battery pack 1 includes a cavity 2 made of aluminum alloy material, the shape and size of the cavity 2 are the same as those of a cylinder The shape and size of the battery are adapted, the battery is placed in the cavity 2, a plurality of grooves 3 are opened on one side of the aluminum alloy cavity 2, and a plurality of grooves 3 are opened on the other side of the aluminum alloy cavity. A plurality of ribs 4 are matched with the grooves 3 and the ribs 4 , and adjacent battery packs 1 are snapped together through the grooves 3 and the ribs 4 .

[0017] The assembled battery pack of the present invention has wide applicability, can freely combine batteries in series and parallel according to vehicle models, and has low production cost. The overall strength of the battery pack with aluminum alloy structure is high, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com