Light emitting diode (LED) dimming color temperature adjusting circuit

A color temperature, LED light string technology, applied in the field of lighting, can solve the problem of insufficient adjustment levels, and achieve the effect of precise adjustment of color temperature and brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

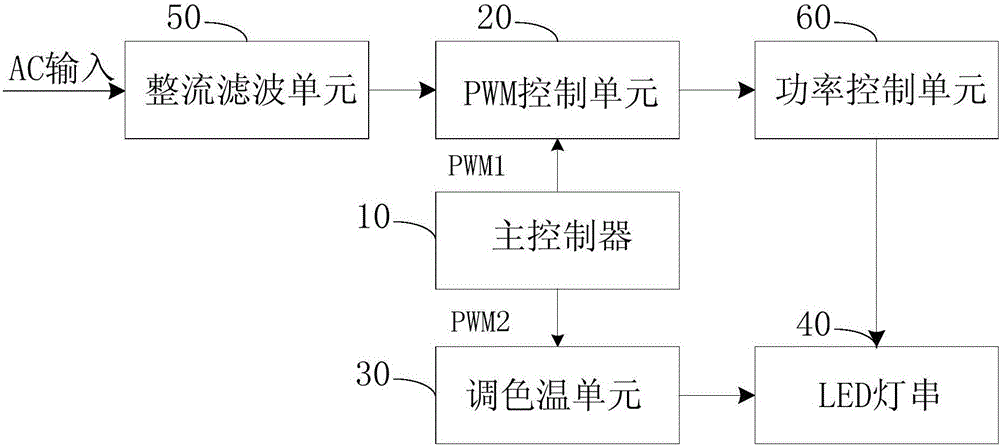

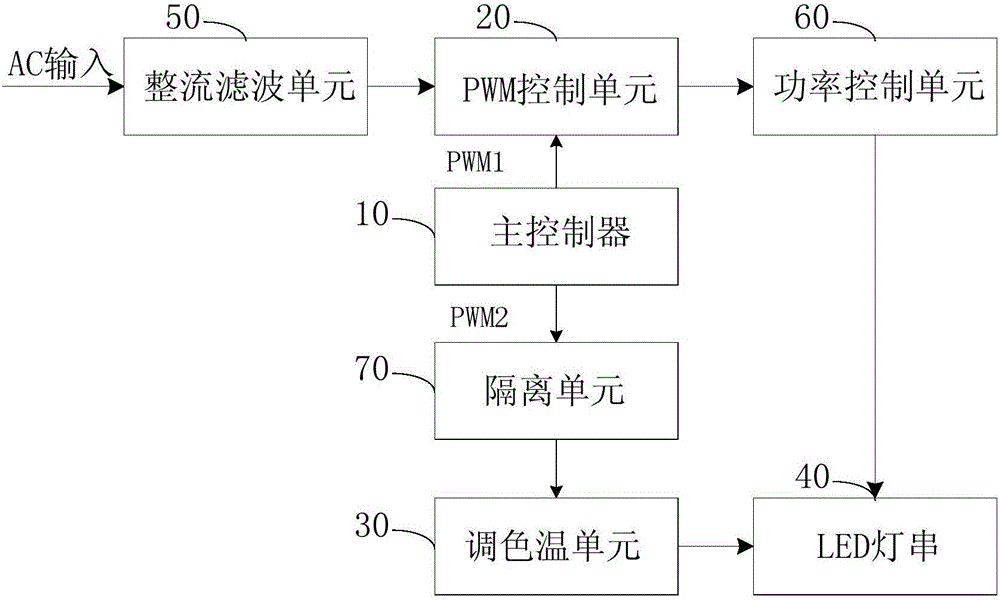

[0036] refer to figure 1As shown, in some embodiments of the present invention, the LED dimming and color temperature circuit includes a main controller 10, a PWM control unit 20 and a color temperature unit 30, wherein the main controller 10 is used to generate One path of dimming PWM signal PWM1 and one path of color temperature PWM signal PWM2, the input side of the PWM control unit 20 is connected to the AC input end through a rectification and filtering unit 50, and the output side is connected to the LED lamp through a power control unit 60 connected in series 40, the PWM control unit 20 receives the dimming PWM signal from the main controller 10 and completes the level conversion, and then outputs a first PWM control signal that controls the on-off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com