Fiber optic coupler array

一种光纤波导、接合部的技术,应用在波导输入和输出耦合器领域,能够解决弱偏振依赖性、集成电路制作和封装复杂、增加成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

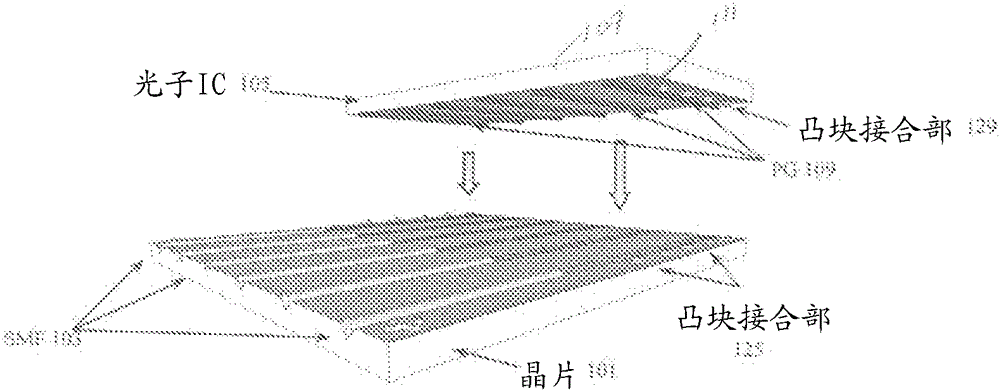

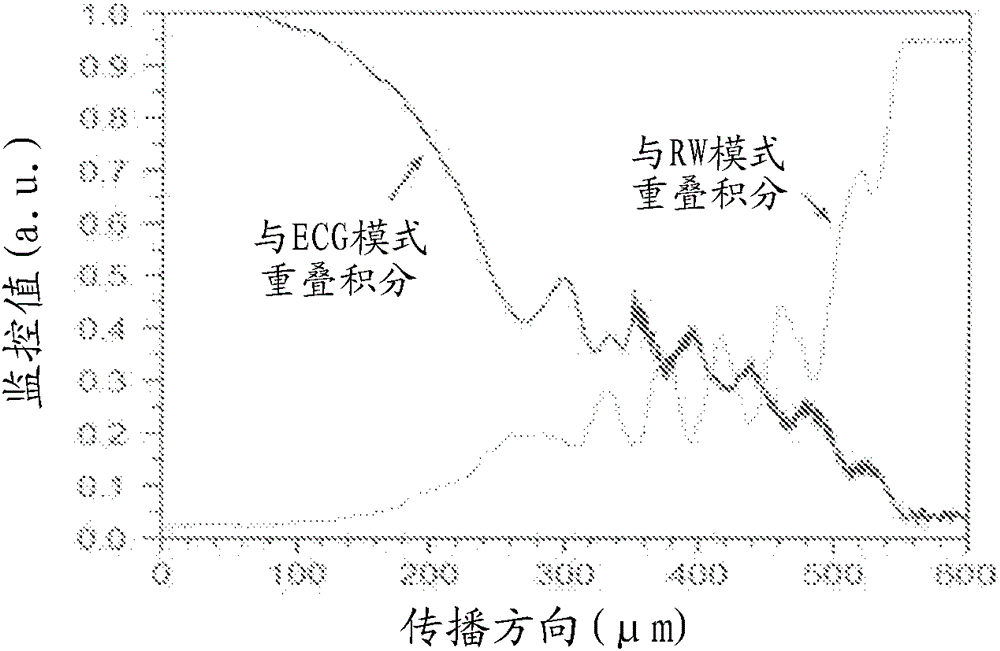

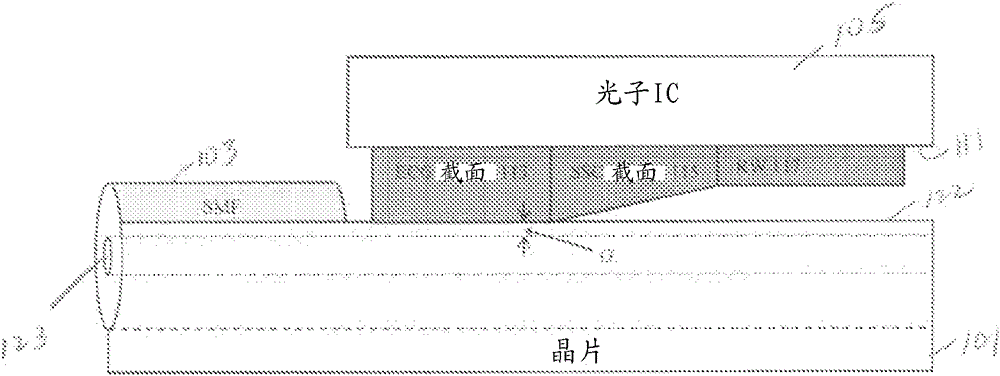

[0026] figure 1 A fiber optic coupler array 100 in accordance with the present application is illustrated. The coupler array 100 consists of two parts: a wafer 101 mechanically supporting a plurality of single-mode optical fibers (SMF) 103; and a photonic integrated circuit (IC) 105 having active electro-optical components operatively coupled to SMF 103 supported by wafer 101 . SMF 103 can extend beyond the periphery of die 101 for connection to other network components as required. Photonic IC 105 is configured in an upside-down configuration (with substrate 107 facing up), with on-chip passive semiconductor waveguide (PG) 109 being an integral part of its top surface 111 (opposite substrate 107 ). Each PG 109 is configured such that it is in intimate contact with a corresponding SMF 103 in which the fiber cross-section has been suitably modified to provide evanescent wave coupling between the SMF 103 and the PG 109 . as in image 3 and 6 As best shown in , each PG 109 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com