Dust remover

A technology of dust collector and dust removal box, which is applied in the field of machinery, can solve problems such as explosion and fire extinguishing treatment, achieve high dust removal efficiency, and improve the effect of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

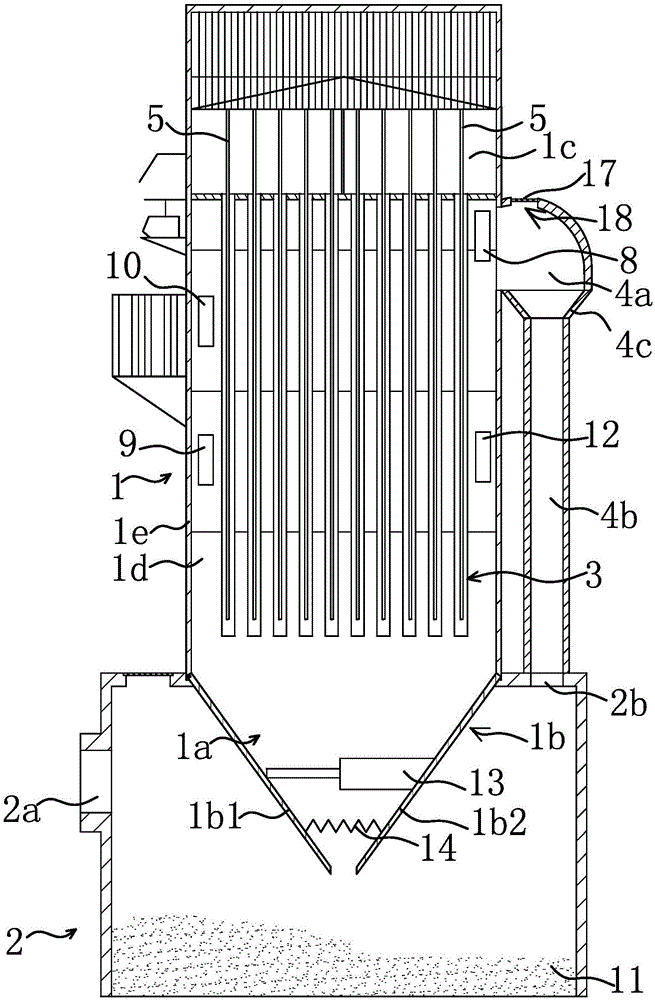

[0039] Such as figure 1 , figure 2 Shown, a kind of dust remover comprises dust removal box 1 and is positioned at dust storage box 2 below dust removal box 1, and dust removal box 1 is fixedly connected with dust storage box 2; Dust removal box 1 comprises dust removal chamber 1d and clean air chamber 1c, described A filter bag 3 is fixedly connected to the dust removal chamber 1d; after the air flows through the filter bag 3, the dust 11 is absorbed and then discharged again. The filter bag 3 can be a cloth bag or a filter cartridge, as long as it can achieve the effect of filtering the dust 11 . The ash storage box 2 is provided with a primary air inlet 2a and a primary air outlet 2b connected with the inner cavity of the ash storage box 2. The wind with dust 11 will first enter the ash storage box 2, and then pass through the ash storage box 2. To the dust removal box 1, the primary air outlet 2b of the ash storage box 2 is connected to the vertical branch pipe 4b, and ...

Embodiment 2

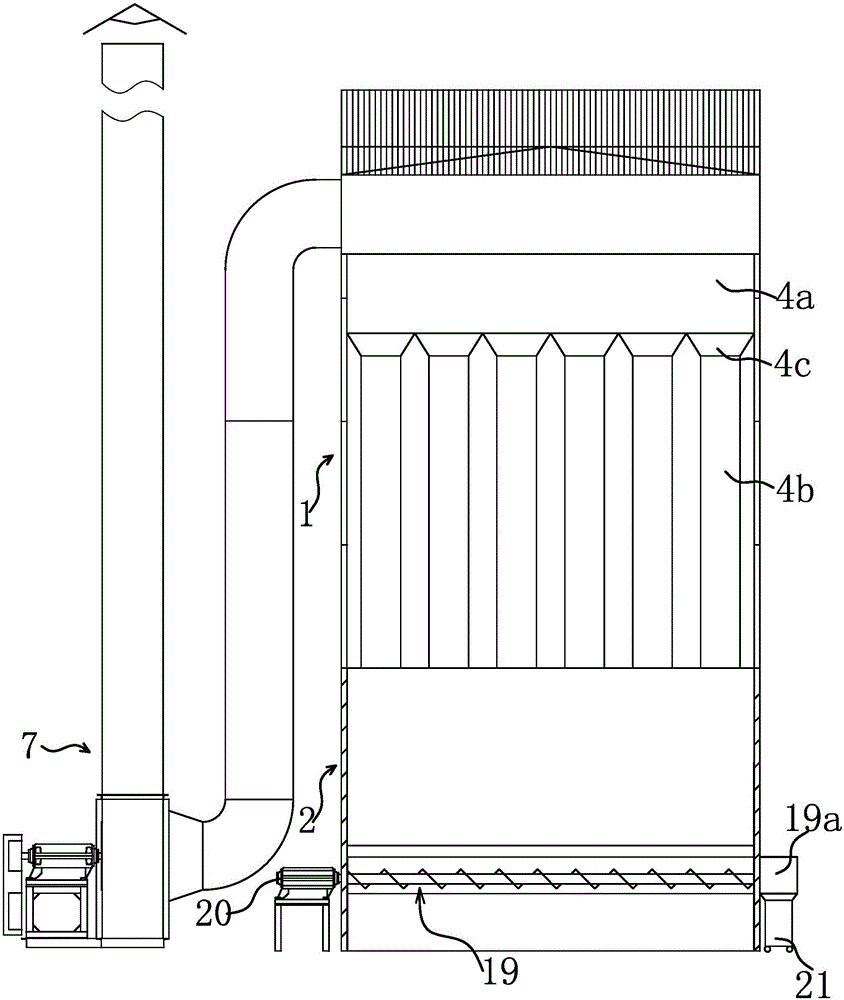

[0046] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is: the control element in this embodiment is a screw conveyor 19, and a motor for driving the screw conveyor 19 is arranged outside the dust removal box 1 20. Due to the poor working environment in the dust removal box 1, if the motor 20 is installed in it, it is easy to cause damage, so the motor 20 is installed on the bottom outside the dust removal box 1, between the first side plate 1b1 and the second side plate 1b2. A screw conveyor 19 is installed between the formed dust collection channel 1a and the motor 20, and the dust 11 at the bottom of the ash storage box 2 is transported to the outside of the dust removal box 1 for centralized recovery through the screw conveyor 19. For example, the ash outlet 19a of the spiral conveyor 19 can be positioned at the outside of the dust removal box 1, and the dust collection box 21 is connected below the ash outlet 19...

Embodiment 3

[0048] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the fixing member includes a hinge 15, at least one ash discharge side plate 1b is hinged with the upper side plate 1e and the ash discharge side plate 1b is fixedly connected with the bottom of another ash discharge side plate 1b through a hinge 15 . When it is necessary to unload the ash, it is only necessary to remove the hinge 15, without the constraints of the hinge 15, at least one ash unloading side plate 1b is placed in a vertical state under the action of gravity, and its bottom edge is in contact with the adjacent A gap is formed between the ash discharge side plates 1b, and the ash collection channel 1a is in a connected state, and due to the blocking effect of the ash discharge side plates 1b, no ash phenomenon will occur during ash discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com