Combustor inlet energy-saving device

An energy-saving device and burner technology, which is applied in the combustion method, combustion engine, charging system, etc., can solve the problems of small contact area, increased air intake resistance, and affect the function of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

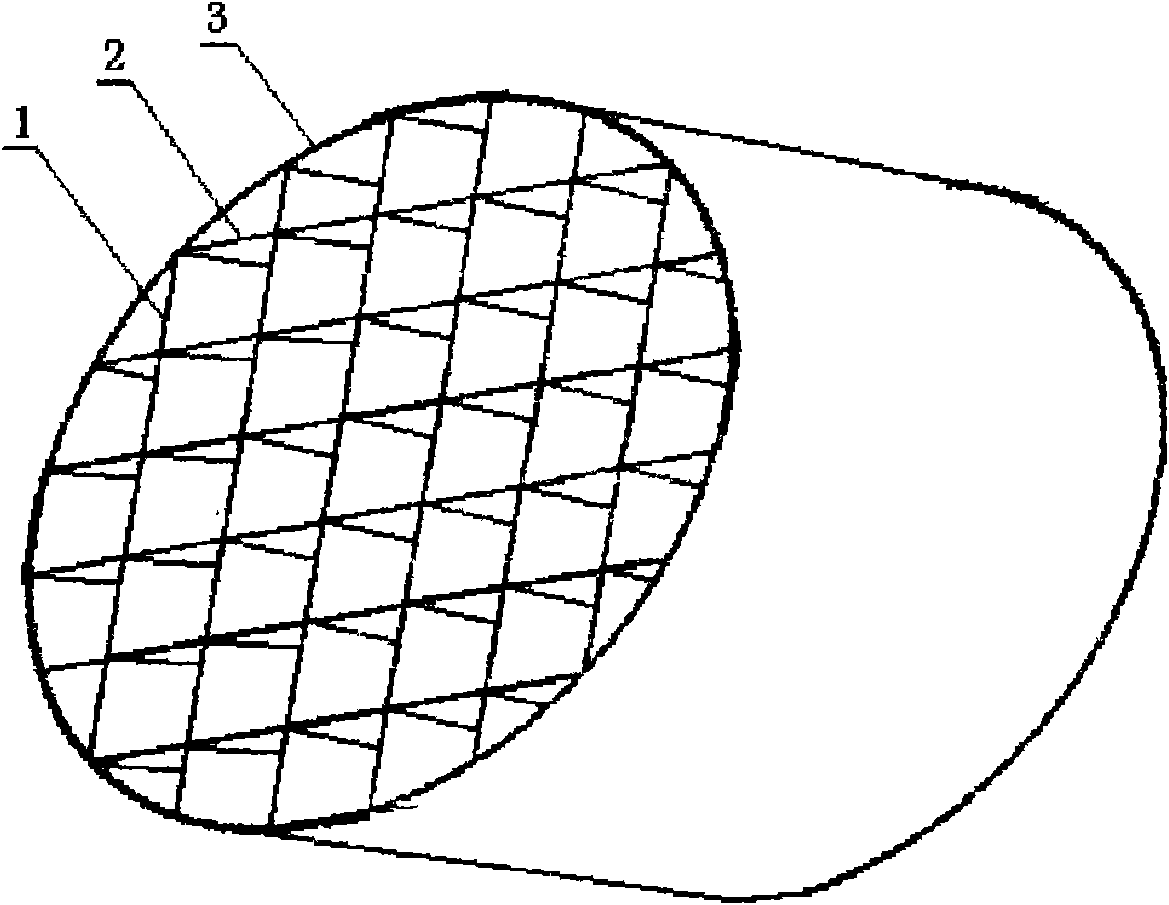

[0007] Attached figure 1 Explain that 1 in the figure below is a vertical partition, which is made of a thinner steel plate or corrugated steel plate of 1 to 2 mm. 2 is a flat partition, along the direction of the pipeline, it is also made of 1 to 2mm thinner steel plate or corrugated steel plate. 3 is a cylinder, made of 2~3mm steel plate, it is slightly smaller than the inner diameter of the air inlet duct so that it can be put into the duct. The welding between the three is firm. Then dip functional paint. Fix 3 in the pipe after the paint is completely dry. This kind of round is generally placed in the oil inlet pipe.

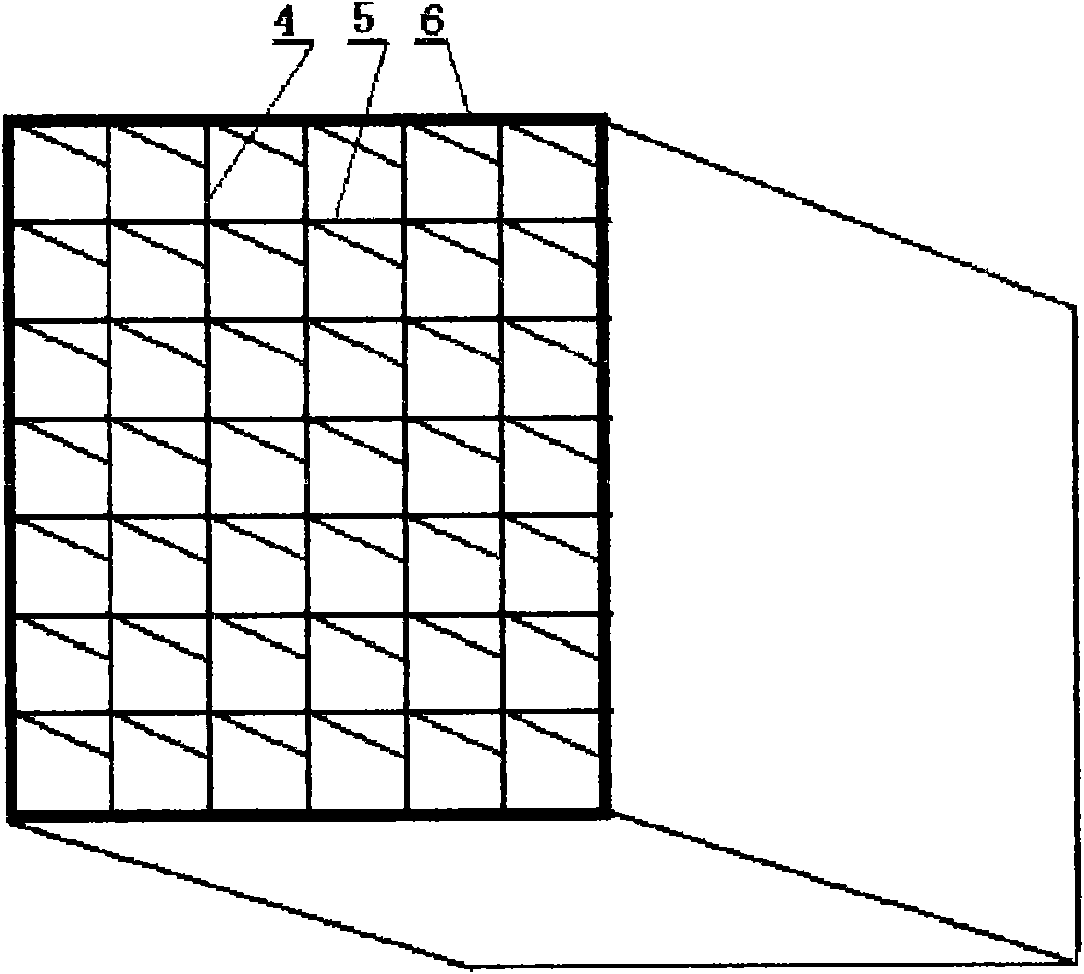

[0008] Attached figure 2 It is square. In the figure, 4 is a vertical partition, which is made of a thinner steel plate or corrugated steel plate with a thickness of 1 to 2 mm. 5 is a flat partition, which is also made of 1~2mm thinner steel plate or corrugated steel plate along the direction of the pipeline. 6 is a box, made of 2~3mm steel plate, it is slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com