Lead-acid storage battery plate curing frame and preparation technology of lead-acid storage battery plates

A lead-acid battery, plate solidification technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of large battery resistance, poor consistency of raw plate components, large power or heat consumption, etc., to achieve uniform heat circulation and reduce costs , the effect of consistent chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation technology of lead-acid battery pole plate of the present invention comprises the following steps,

[0021] S1, prepared apparent specific gravity 4.0g / cm 3 ~4.6g / cm 3 lead paste, and spread the lead paste on the grid;

[0022] S2, rolling the grid to obtain a pole plate;

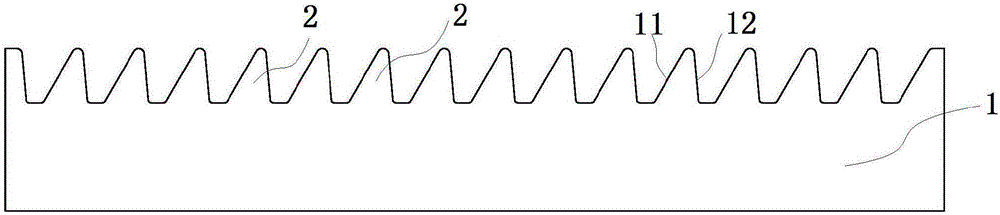

[0023] S3, fixing the polar plates sequentially on the curing rack described in the first aspect of the present invention, inserting a row of polar plates into each adjacent protruding tooth 2;

[0024] S4, sending the curing frame with fixed pole plate into the curing drying room for curing.

[0025] By adjusting the specific gravity of the lead paste and setting the protruding teeth 2, the problems of sticking tape and sticking board that may exist after the acid-free leaching can be solved.

Embodiment 1

[0028] First, put in a specified amount of lead powder, sulfuric acid, water, and auxiliary materials to prepare a compound with an apparent specific gravity of 4.0g / cm 3 ~4.6g / cm 3 lead paste, and spread the lead paste on the grid;

[0029] Secondly, the grid filled with lead paste is rolled to obtain the pole plate;

[0030] Then, the rolled plate is conveyed on the conveyor belt in a single piece, the piece is picked up manually, the plate is placed vertically on the fixed frame, the plate is lifted from the bottom, and the plate is scattered along the inclined direction , so that each adjacent protruding tooth 2 of the fixing frame is inserted into a row of pole plates;

[0031] Finally, the multi-layer curing racks are stacked and sent to the curing drying room for curing.

[0032] The cost advantage of the preparation method of the present invention is:

[0033] (1) Fixture cost: Calculated on the basis of a production line: the processing fee for protruding teeth 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com