Testing device used for testing resin liquid components

A test device and resin liquid technology, applied in the direction of mixers with rotating stirring devices, material inspection products, dissolution, etc., can solve the problems of large volume and waste of pre-processing mechanisms, so as to facilitate popularization and application and improve product quality , the effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

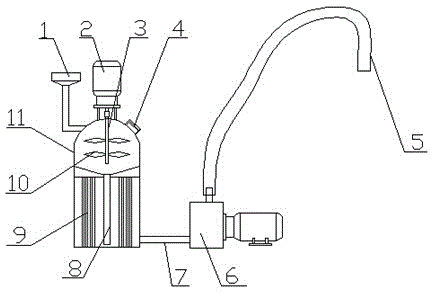

[0008] Depend on figure 1 It is known that a test device for testing resin liquid components is composed of a stirring mechanism and a filtering mechanism. The stirring mechanism is composed of a stirring motor 2, a power shaft 3, an observation port 4, a tank body 11, and a stirring blade 10; composition.

[0009] The stirring mechanism, when the raw material is injected into the tank body 11, the stirring motor 2 starts to rotate, and the rotation of the electrical appliance drives the power shaft 3 and the stirring blade 10 to rotate, and the blade 10 stirs the raw material. 11 for observation. The filter mechanism enters the filter screen 9 through the feed pipe 8 after the raw material is stirred, and after the raw material is filtered through the filter screen 9, it is sucked out of the tank body 11 by the electric pump 6 through the discharge pipe 7.

[0010] When the present invention is in use, the raw materials to be tested are manually poured into the hopper 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com