Granulator convenient to adjust

The technology of a granulator and a rack is applied in the field of granulators that are easy to adjust, which can solve the problems of troublesome cleaning of the discharge tray, and achieve the effects of easy adjustment, convenient cleaning and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

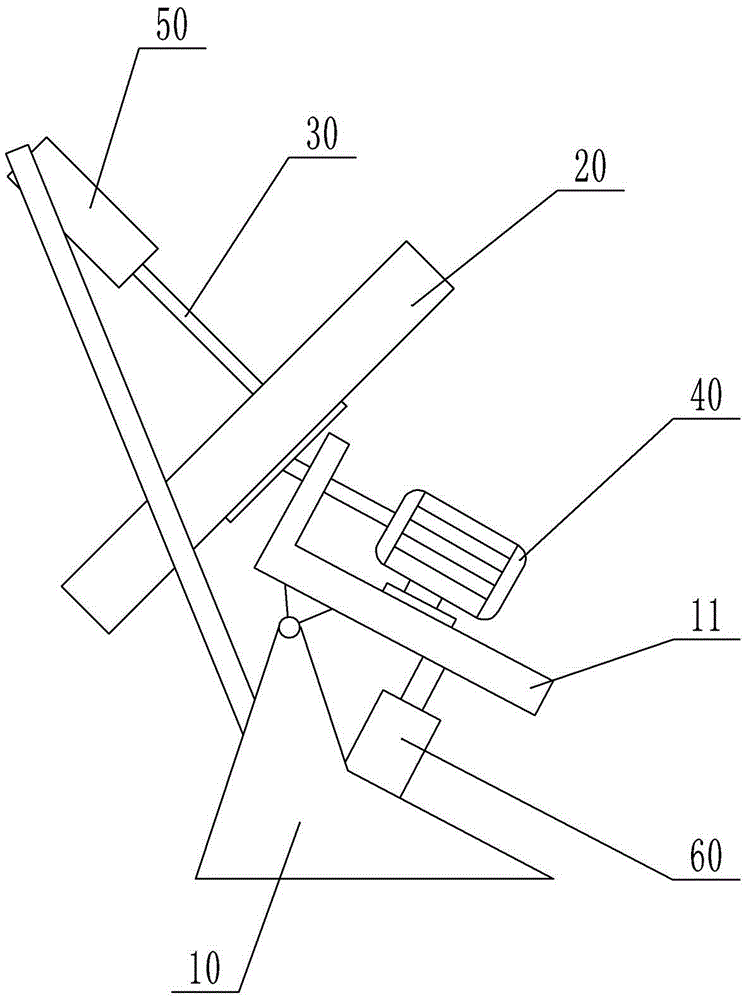

[0015] The reference numerals in the accompanying drawings of the description include: frame 10 , support base 11 , discharge tray 20 , scraper 30 , servo motor 40 , worm gear screw lifter 50 , and hydraulic jack 60 .

[0016] Such as figure 1 As shown, the granulator that is easy to adjust includes a discharge tray 20, a scraper 30, a nozzle, a servo motor 40 and a frame. The discharge tray is installed at the output end of the servo motor 40 and is set at an angle of 55° to the ground. The shower head faces the discharge tray 20. The inner wall and the bottom plate of the discharge tray 20 are covered with a layer of polypropylene plastic plate, which can reduce the adhesion of materials in the discharge tray 20 and make it easier to clean. In addition, it also includes a support base 11 , a QF electro-hydraulic jack 60 and a SWL series worm screw lifter 50 , the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com