Blocky coal smashing device

A pulverizing device and coal technology, applied in grain processing and other directions, can solve the problems of unstable working current of the motor, reducing the service life of equipment, equipment wear or damage, etc., to achieve the effect of promoting the value of use and ensuring the material flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

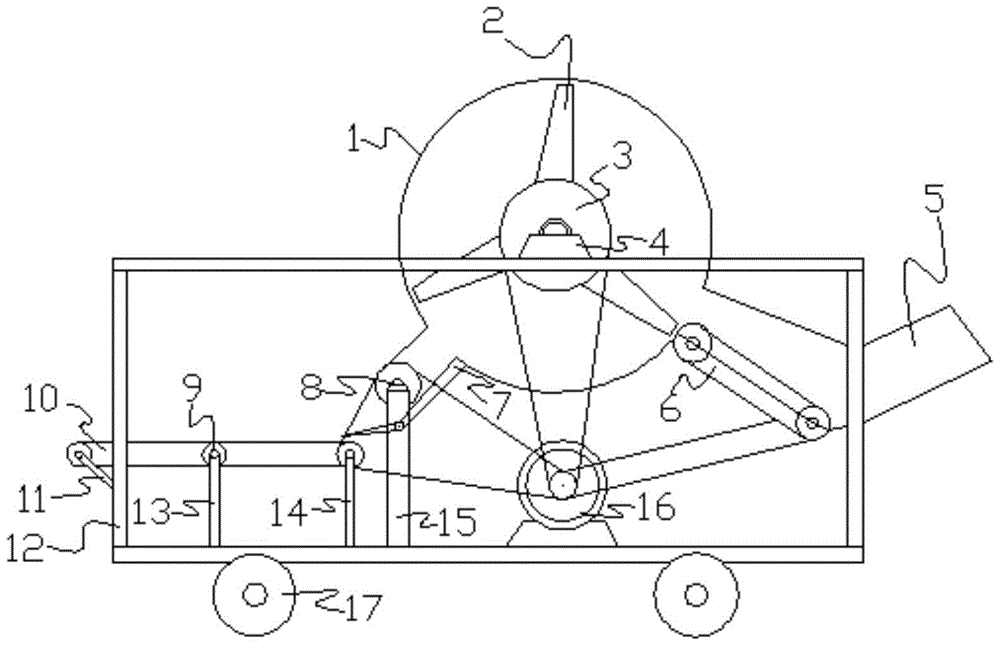

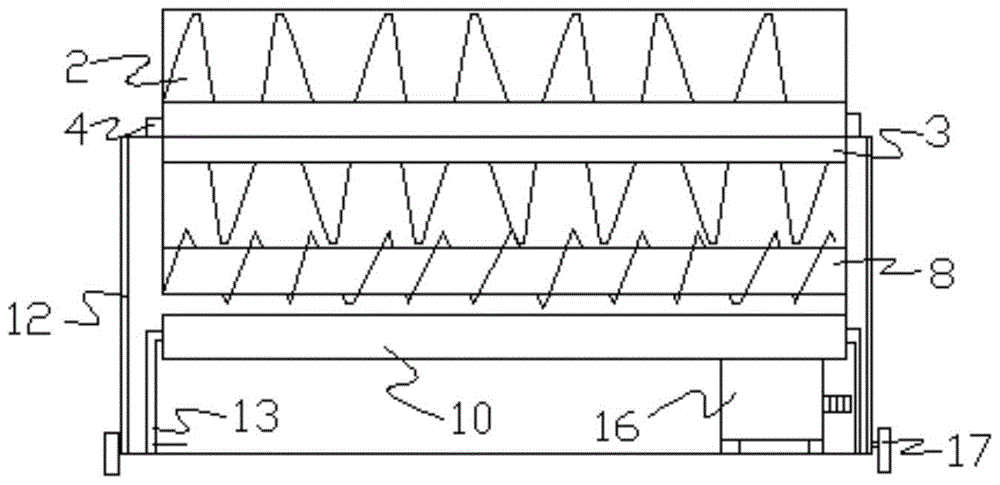

[0018] Such as figure 1 , figure 2 As shown, the structure of this kind of block coal crushing device includes a crushing bin with two ends closed in the transverse direction. The crushing bin includes a bin wall 1, a tapered convex post 2 and a rotating shaft 3. A rotating shaft 3 is provided in the middle of the interior of the crushing bin. The upper surface of the rotating shaft 3 is provided with a tapered boss 2. The crushing bin is fixed on the frame 12 through a fixed support 4. The crushing bin is directly below the A motor 16 is provided, and the rotating shaft 3 is connected with the motor 16 through a belt. When in use, the rotating shaft is driven by the motor, thereby driving the rotation of the conical protrusion, and the conical protrusion crushes the coal blocks entering the crushing bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com