Damping corrugated board

A corrugated cardboard and corrugated paper technology, applied in the field of corrugated cardboard, can solve problems such as weak impact resistance, increased space occupied by packaging boxes, waste of resources, etc., and achieve the effect of improving impact resistance and saving packaging space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

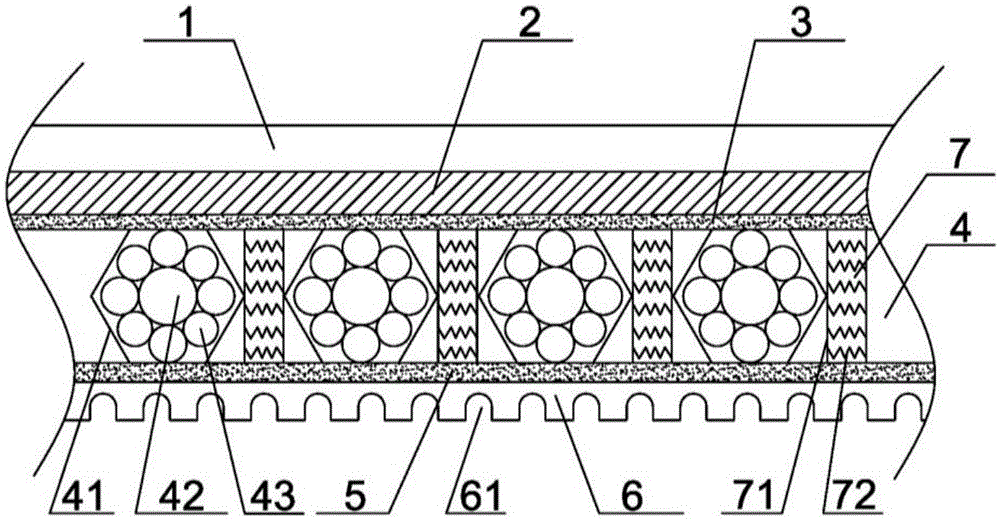

[0011] refer to figure 1 As shown, a kind of corrugated cardboard comprises an outer layer of cardboard paper 1 and an inner layer of cardboard paper 6, the bottom of the outer layer of cardboard paper 1 is provided with a waterproof adhesive layer 2, and the bottom of the described waterproof adhesive layer 2 is provided with The first glue layer 3, the corrugated paper core 4 is arranged under the first glue layer 3, the second glue layer 5 is arranged under the corrugated paper core 4, and the inner box is arranged under the second glue layer 5 Cardboard6.

[0012] The corrugated paper core 4 is composed of a hexagonal paper core 41 and a buffer layer 7 arranged at intervals. The hexagonal paper core 41 is provided with a central circular paper core 42 and a number of paper cores tangent to the outer circumference of the central circular paper core. Small round paper cores 43, preferably eight small round paper cores 43. The hexagonal paper core 41, the central circular p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com