Automatic opening device for container twist locks

An automatic unlocking and container technology, applied in the field of port machinery, can solve problems such as low efficiency of manual unlocking, and achieve the effect of overcoming insufficient security, overcoming low efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A specific embodiment of the present invention will be briefly described below in conjunction with the accompanying drawings.

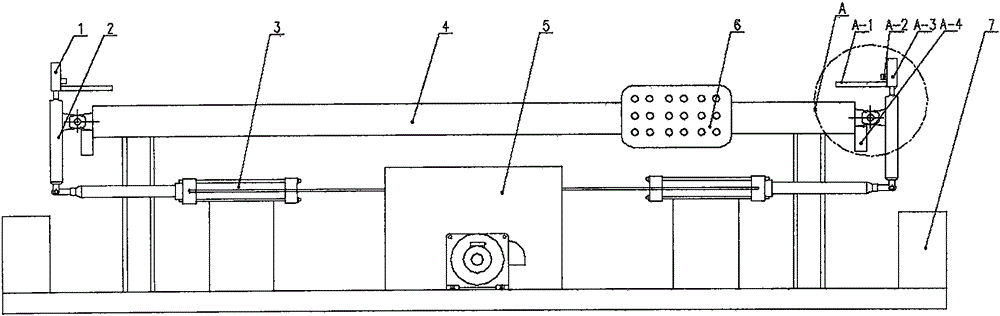

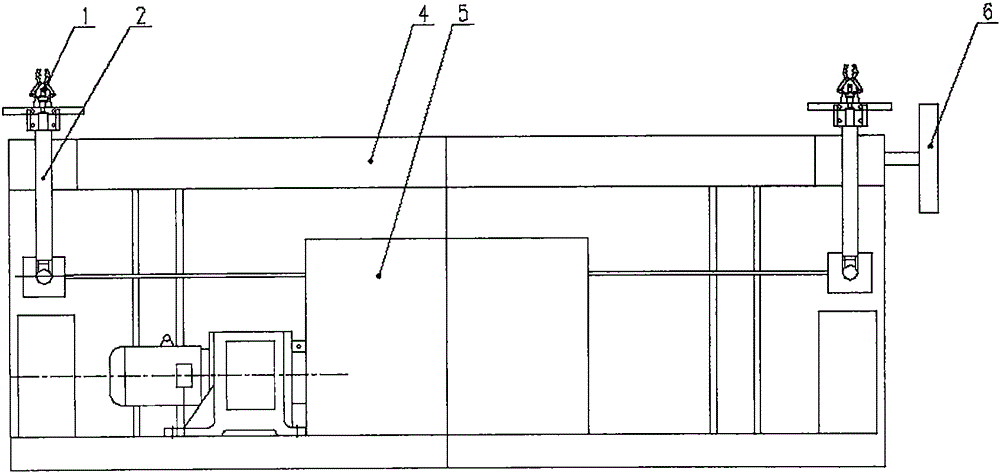

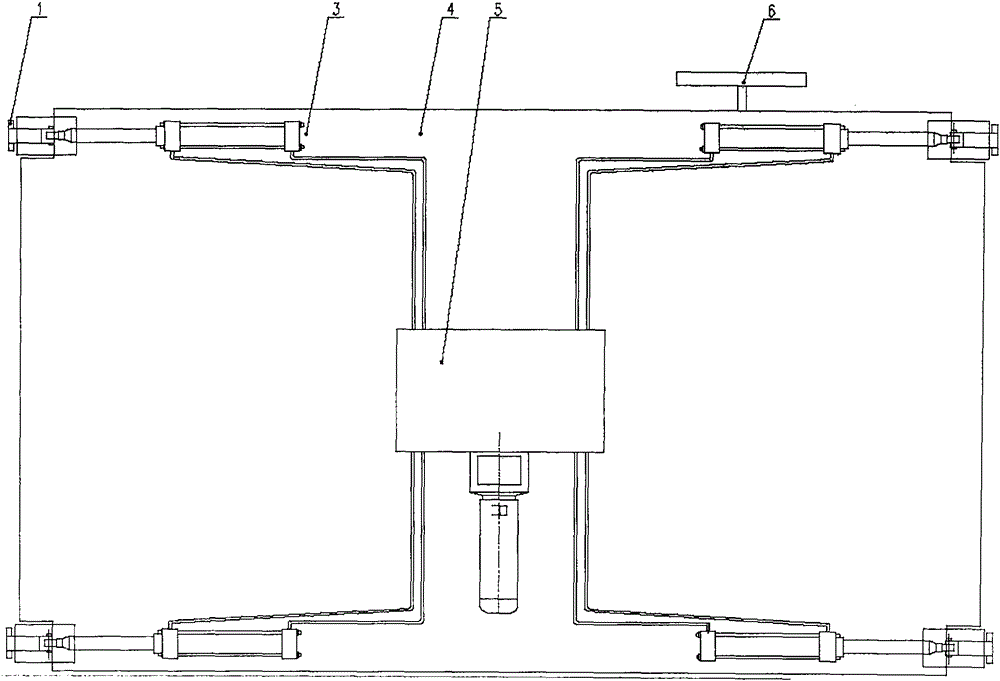

[0026] Such as figure 1 , 2 , As shown in 3 and 4, the container twist lock automatic unlocking device is mainly composed of an unlocking actuator 1, a claw bracket 2, a linear thruster 3, a working platform 4, a power system 5, a control system 6, and a twist lock collection box 7.

[0027] The container twist lock automatic unlocking device is characterized in that the claw bracket 2 is hinged with the working platform 4, the linear pusher 3 is hinged with the claw bracket 2, and the linear pusher 3 is powered by the power system 5; the twist lock collection box 7 It is arranged under the claw bracket 2, which is convenient for collecting the twist locks that have been taken off.

[0028] The unlocking actuator 1 includes several jaw assemblies A. Each assembly described includes twist lock receiving tray A-1, visual identification system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com