Vertical material weighting operation device

A technology of operating devices and materials, which is applied in the field of oil drilling, can solve problems such as difficult on-site disassembly, complicated on-site construction, and threat to service life, and achieve the effects of efficient loading and unloading operations, reduced labor intensity, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the vertical material weighing operation device of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0045] The invention provides a vertical material weighting operation device.

[0046] In an exemplary embodiment of the present invention, the working device may include: at least one storage tank system and one weighing system, for example, may include 2 to 5 storage tank systems.

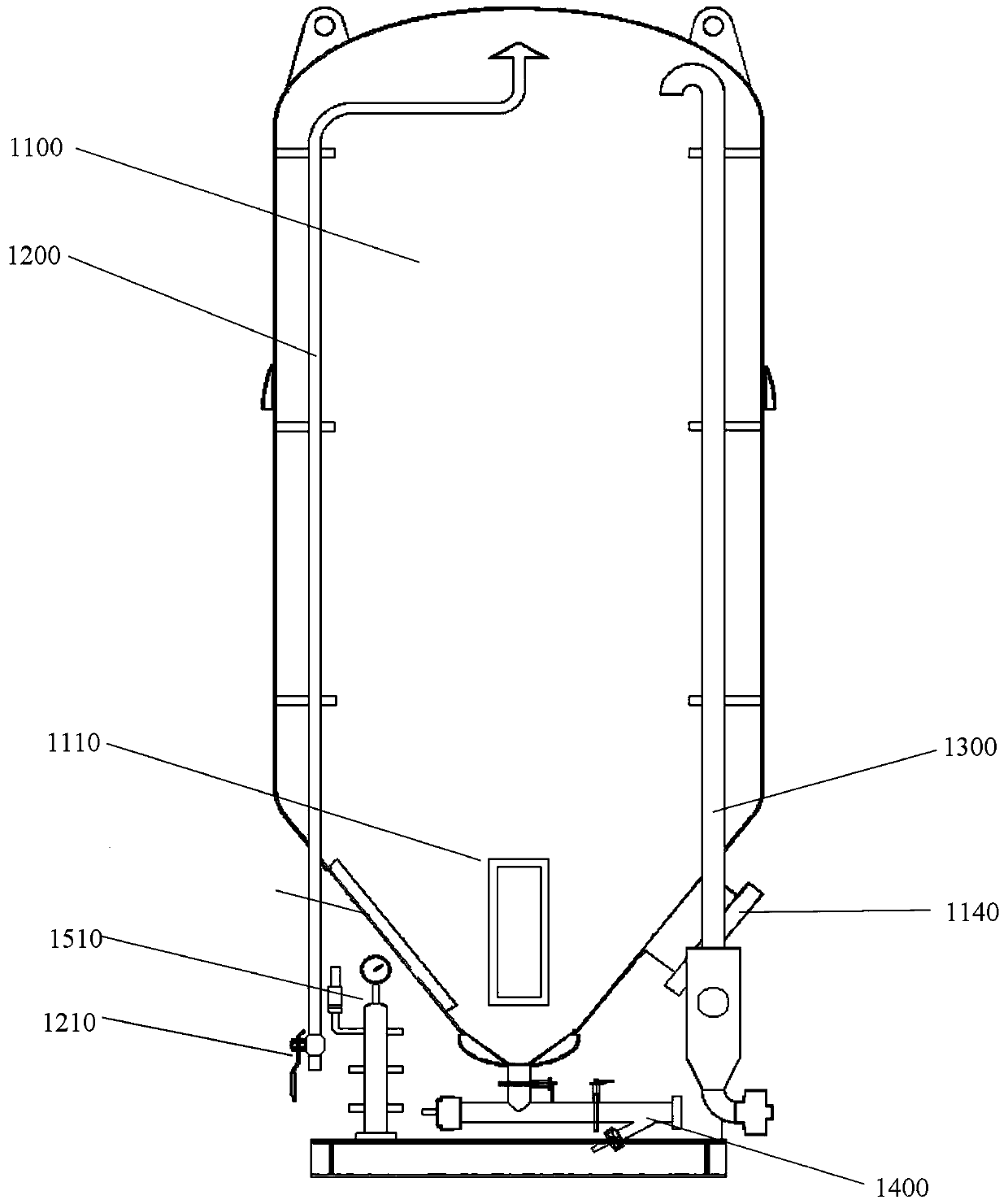

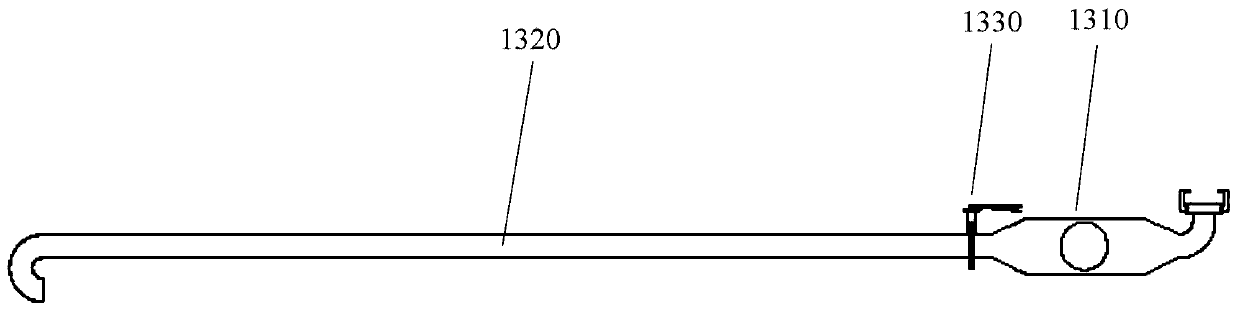

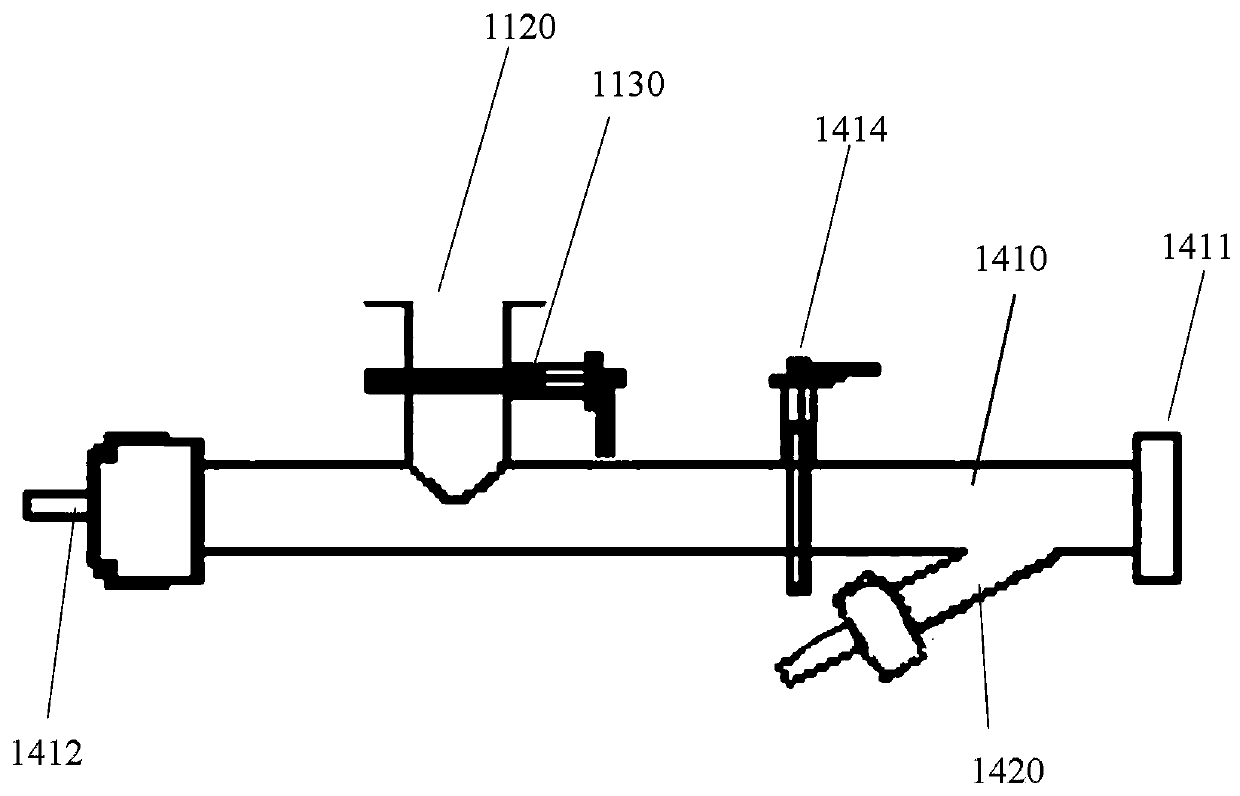

[0047] Such as figure 1 As shown, each storage tank system may include: a tank body 1100, an exhaust pipe 1200, a feeding unit 1300, a discharging unit 1400, a gas distribution unit (not shown in the figure), a base (not shown in the figure) .

[0048] The tank body 1100 can be used to store materials. The tank body 1100 can be a sealing device with a cavity structure. The tank body can include first, second and third parts arranged from top to bottom. The first part can be a hollow spherical segment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com