Transport loading & unloading apparatus

A technology of loading and unloading devices and conveying devices, which is applied in the directions of conveyors, loading/unloading, transportation and packaging, etc., and can solve problems such as large devices, inability to perform unloading operations, and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

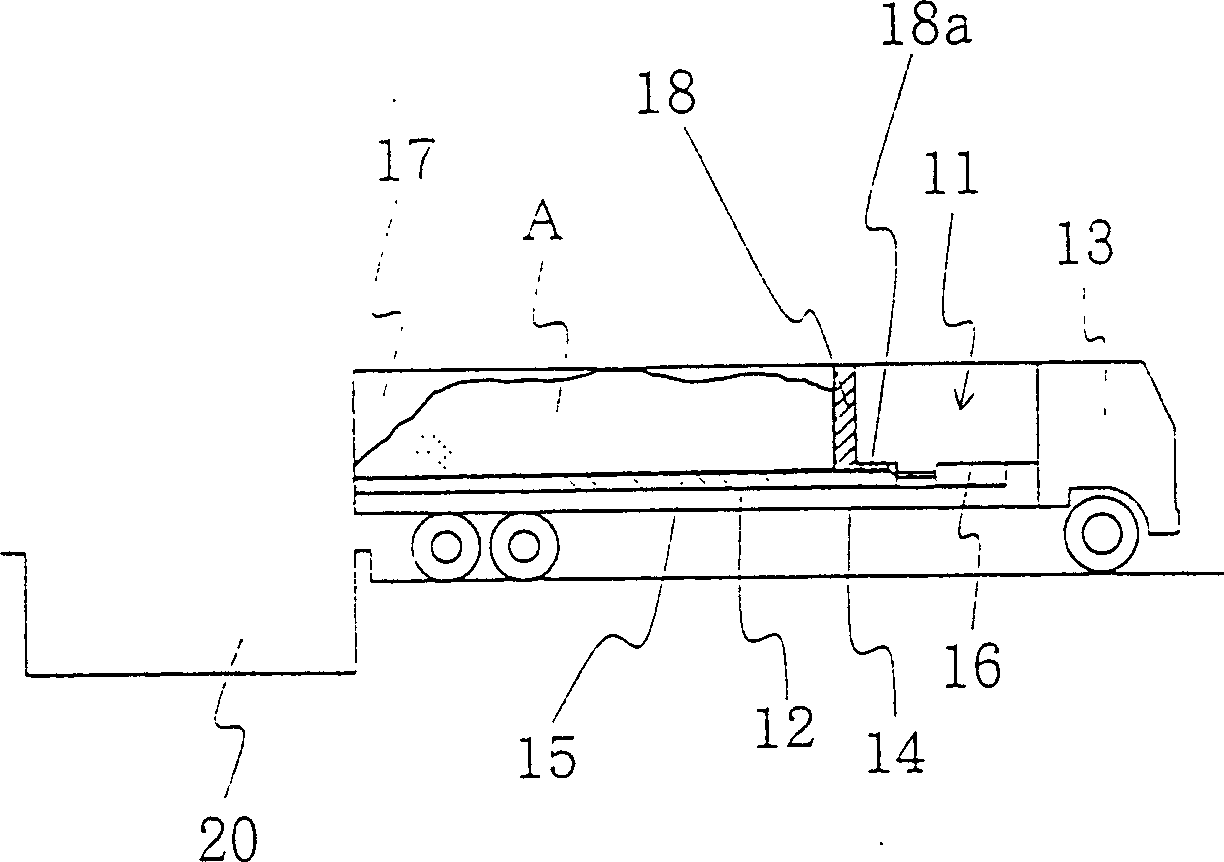

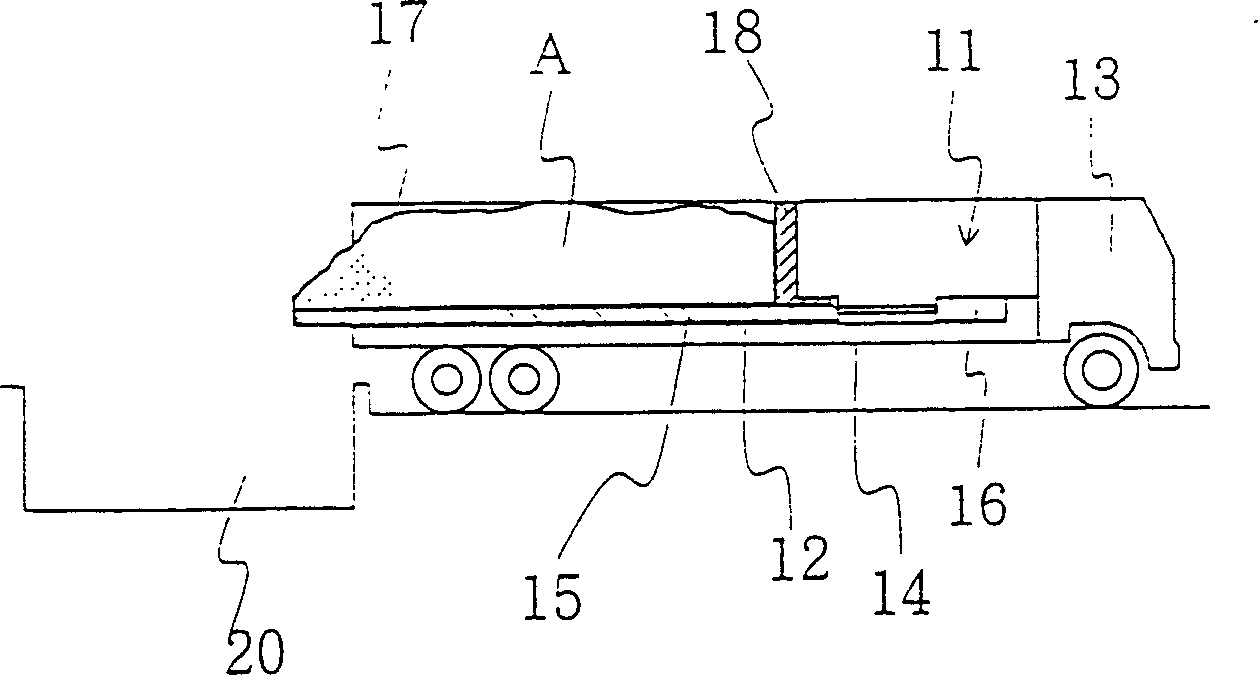

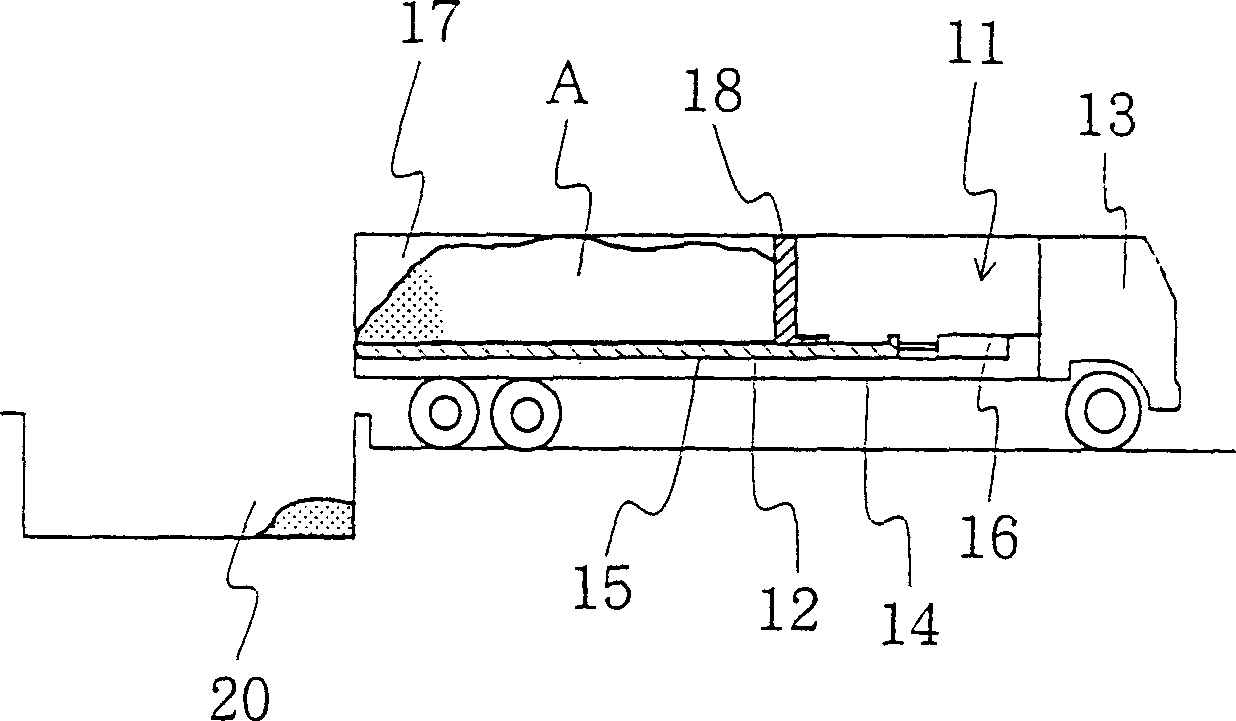

[0036] Figure 1 to Figure 9 It is the first embodiment of the transportation loading and unloading device of the present invention, showing the longitudinal sectional views of the first process to the ninth process when it is used in the truck container unloading device. Figure 10 ~ Figure 18 It is a plan view of the said 1st process - 9th process. Among the figure, 11 is a truck, 12 is a container, and 13 is a cab. The truck 11 is loaded with chipped goods such as iron scraps or granular goods A such as gravel, and is transported.

[0037] The container 12 of the truck 11 has an open rear end. In the present invention, on the base plate 14 of the container 12, a slide plate 15 with the same width as the base plate 14 is placed. The slide plate 15 is made of a steel plate or the like, and an air cylinder 16 for moving the slide plate 15 forward and backwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com