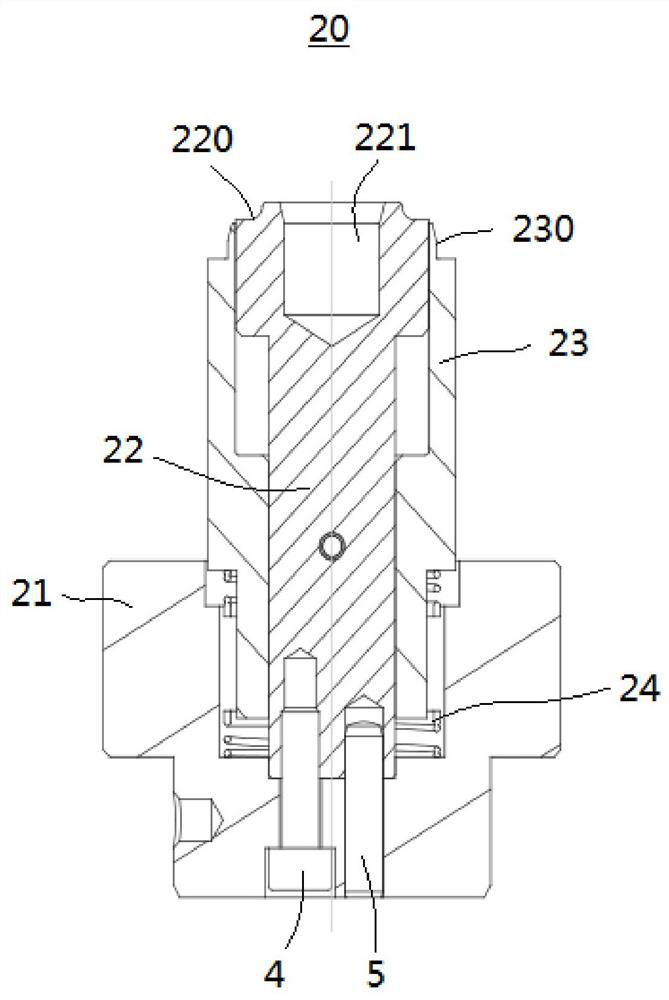

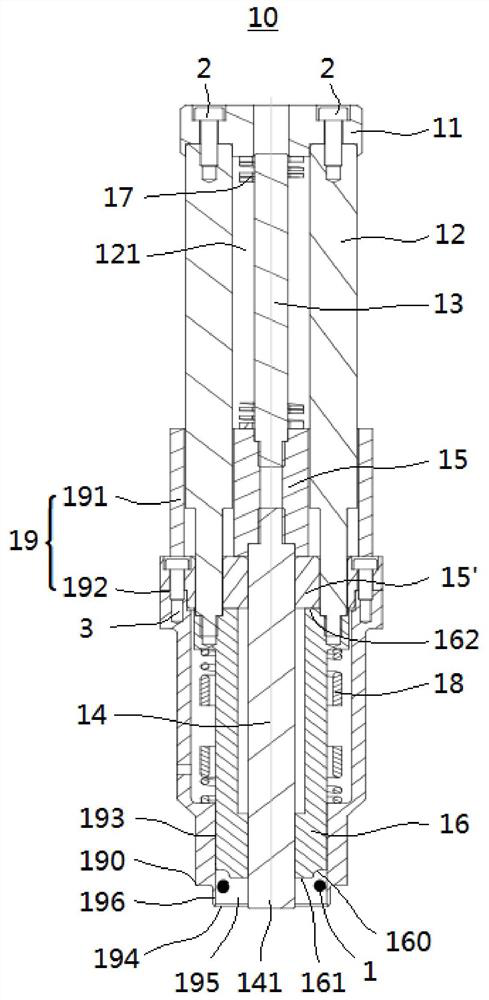

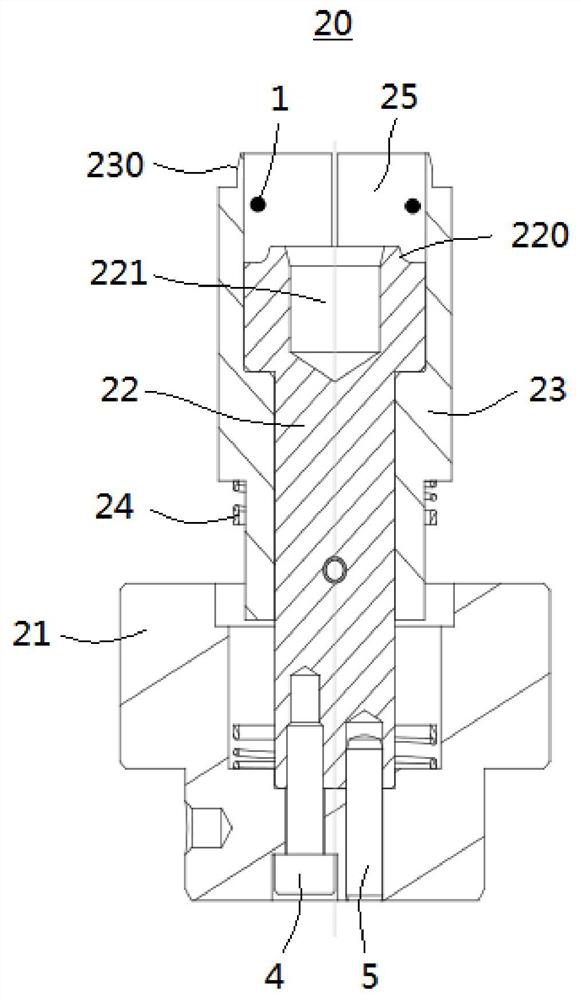

O-shaped ring taking and installing device, O-shaped ring installing assembly and O-shaped ring installing method

A technology for installing components and O-rings, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of relying on the technical level of the staff, unreliable installation quality, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] First of all, it should be noted that the structural composition, features and advantages of the O-ring installation device, O-ring installation assembly and O-ring installation method of the present invention will be described in detail below by way of example, but all descriptions are only It is used for illustration and does not constitute any limitation of the present invention. In this article, the technical term "O-ring" generally refers to various hole sealing rings made of materials such as rubber, rather than shaft sealing rings. The technical terms "first" and "second" are only used For purposes of distinguishing representations and not intended to indicate their order and relative importance, the technical term "connected (or connected, etc.)" covers the direct connection of a particular part to another part and / or the indirect connection to another part, the technical term "Up", "Down", "Top", "Bottom", "Front", "Rear", "Inner", "Outer" and their derivatives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com