Rope head seat for non-machine-room lift car

A technology without machine room and rope head, applied in the field of elevators, can solve the problems of no reserved holes, nowhere to fix the auxiliary channel steel, no damage to the house beams, etc., so as to reduce the burden, the structure is stable, and the connection is tight. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

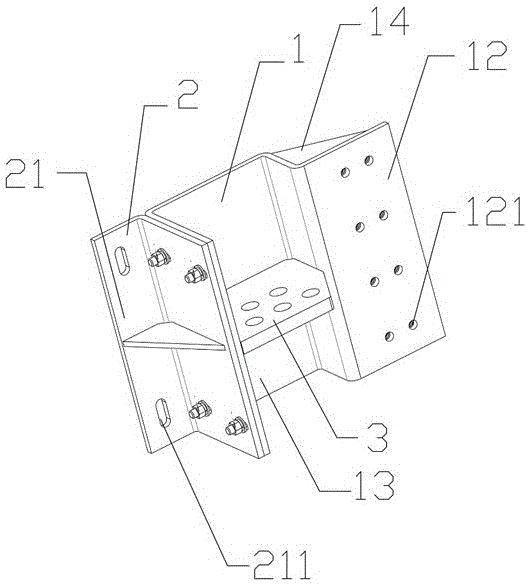

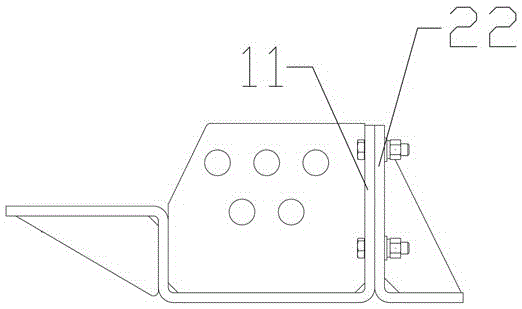

[0017] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. A machine room-less car rope end seat, comprising a bracket 1 for installing the rope end seat on a guide rail, a bracket assembly 2 for installing the rope end seat on the hoistway wall, a rope end plate 3; and a rope end plate 3 It is fixedly arranged on the bracket 1, and the bracket assembly 2 is detachably arranged on the bracket 1 through bolts.

[0018] In order to improve the connection strength of the bracket 1, the bracket 1 can be bent three times by a steel plate to form the first component mounting surface 11, the guide rail mounting surface 12, and the connecting plate 13, and the connecting plate 13 is arranged on the first component mounting surface 11 and the guide rail mounting surface Between 12. The first component mounting surface 11 is connected to the bracket component 2 , and the guide rail mounting surface 12 is arranged in two ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com