Preparation method of superparamagnetic carrier for crosslinking and immobilizing lipase

A fat immobilization and superparamagnetic technology, applied in the field of food chemistry, can solve problems such as inability to adapt to lipase interface activation characteristics, functional defects, damage, etc., achieve good magnetic separation performance, and overcome the effect of lipase activity-dependent interface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

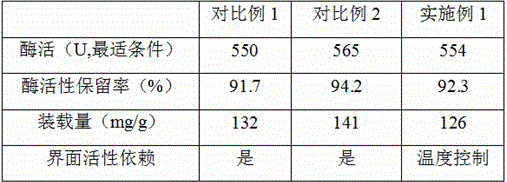

Examples

Embodiment 1

[0024] (1) Nano-magnetic microsphere Fe 3 o 4 Preparation of:

[0025] FeCl 3 ·6H 2 O was dissolved in anhydrous ethylene glycol to prepare a solution with a concentration of 0.13mmol / mL, and then press FeCl 3 ·6H 2 The mass ratio of O to the treatment agent is 1:6. Add the treatment agent, wherein the treatment agent is sodium acetate and polyethylene glycol. After adding the treatment agent, the concentration of sodium acetate is 95mg / mL, and then transfer to the polytetrafluoroethylene coated with inert material. In a reactor made of vinyl fluoride, ultrasonically react at a constant temperature of 200°C for 5 hours. After natural cooling, wash with ethanol and deionized water alternately for several times, then wash with deionized water, and then dry in vacuum to obtain nano-magnetic particles. Ball Fe 3 o 4 ;

[0026] (2) Nano-magnetic microsphere Fe3 o 4 The package:

[0027] Nano magnetic microsphere Fe obtained in step (1) 3 o 4 Mix with the NaOH solution w...

Embodiment 2

[0032] (1) Nano-magnetic microsphere Fe 3 o 4 Preparation of:

[0033] FeCl 3 ·6H 2 O was dissolved in anhydrous ethylene glycol to prepare a solution with a concentration of 0.1mmol / mL, and then press FeCl 3 ·6H 2 The mass ratio of O to the treatment agent is 1:5. Add the treatment agent, wherein the treatment agent is sodium acetate and polyethylene glycol. After adding the treatment agent, the concentration of sodium acetate is 120mg / mL, and then transfer to the polytetrafluoroethylene coated with inert material. In a reactor made of vinyl fluoride, ultrasonically react at a constant temperature of 200°C for 6 hours. After natural cooling, first wash with ethanol and deionized water alternately for several times, then wash with deionized water, and then vacuum dry to obtain nano-magnetic particles. Ball Fe 3 o 4 ;

[0034] (2) Nano-magnetic microsphere Fe 3 o 4 The package:

[0035] Nano magnetic microsphere Fe obtained in step (1) 3 o 4 Mix with the NaOH solut...

Embodiment 3

[0040] (1) Nano-magnetic microsphere Fe 3 o 4 Preparation of:

[0041] FeCl 3 ·6H 2 O was dissolved in anhydrous ethylene glycol to prepare a solution with a concentration of 0.15mmol / mL, and then press FeCl 3 ·6H 2 The mass ratio of O to the treatment agent is 1:4. Add the treatment agent, wherein the treatment agent is sodium acetate and polyethylene glycol. After adding the treatment agent, the concentration of sodium acetate is 80 mg / mL, and then transfer to the polytetrafluoroethylene coated with inert material. In the vinyl fluoride reactor, ultrasonically react at a constant temperature of 200°C for 4 hours. After natural cooling, wash with ethanol and deionized water alternately for several times, then wash with deionized water, and then dry in vacuum to obtain nano-magnetic particles. Ball Fe 3 o 4 ;

[0042] (2) Nano-magnetic microsphere Fe 3 o 4 The package:

[0043] Nano magnetic microsphere Fe obtained in step (1) 3 o 4 Mix with the NaOH solution whos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com