Sealing structure and sealing method for lifting cord hole of metro vehicle

A sealing structure and lead-in technology, which is applied to pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of reducing the service life of sealing structures, complicated on-site construction, and increased maintenance difficulty, and achieves the reduction of the size of the opening , Simplify on-site construction and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

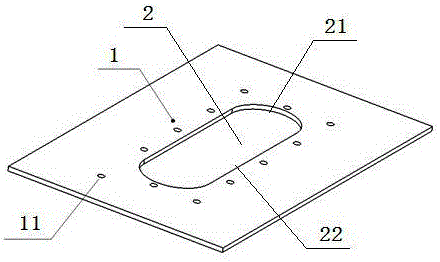

[0053] Such as figure 1 As shown, a lead wire hole 2 is provided on the car body chassis 1 of the subway vehicle. The lead wire hole 2 is a long circular hole with two semicircular holes 21 and a rectangular hole 22 between the two semicircular holes 21 .

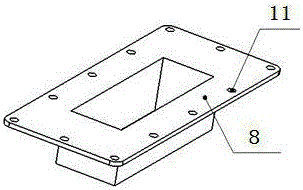

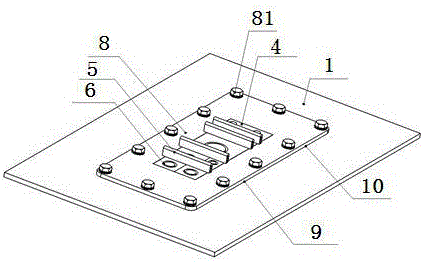

[0054] In the prior art, in order to facilitate the installation of the lead wire clamp block mounting bushing 8 and the bushing mounting fastener 81, it is necessary to set up several such as: figure 1 The bush installation hole 11 shown in the present invention does not need to be provided with the bush installation hole 11 .

[0055] In the present invention, a sealing structure for a lead wire hole of a subway vehicle includes a lead wire clamp block and lubricating oil, and the lead wire clamp block is arranged in the lead wire hole 2 on the car body chassis 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com