Ultrasonic flowmeter with plugging positioning function

An ultrasonic and flowmeter technology, used in the measurement of flow/mass flow, liquid/fluid solid measurement, and measurement devices, etc., can solve the problems of inaccurate positioning, increase production costs, and measure medium leakage, and achieve high measurement accuracy and fixed Reliable, quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is further described:

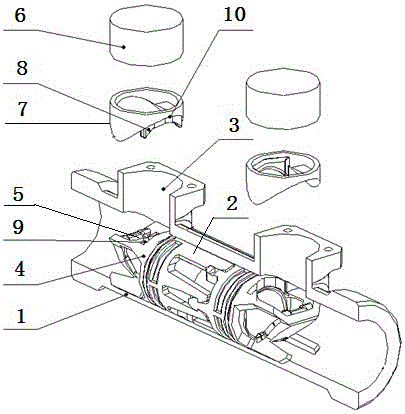

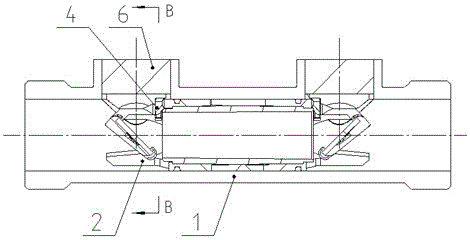

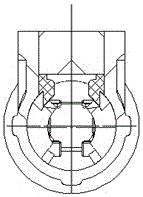

[0017] As shown in the drawings, an ultrasonic flowmeter with plug-in positioning includes a flow pipe body 1, a measuring pipe body 2, a transducer mounting pipe body 3, a reflector mounting seat 4, a reflector 5 and a transducer 6 , the flow pipe body 1, the measuring pipe body 2, the transducer installation pipe body 3, the reflector mounting seat 4, the reflector 5 and the transducer 6 are connected in the same relationship as the prior art, which will not be described in detail here. A positioning sleeve 7 is provided between the flow pipe body 1 and the reflector mounting seat 4, the positioning sleeve 7 is cylindrical, the center of the positioning sleeve 7 is provided with an ultrasonic channel, and the lower end of the positioning sleeve 7 is provided with a positioning insert 8, The positioning insert 8 extends axially along the lower end of the positioning sleeve 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com