Semi-automatic punctuation extensometer

An extensometer and semi-automatic technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of reduced work efficiency and large amount of sample testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

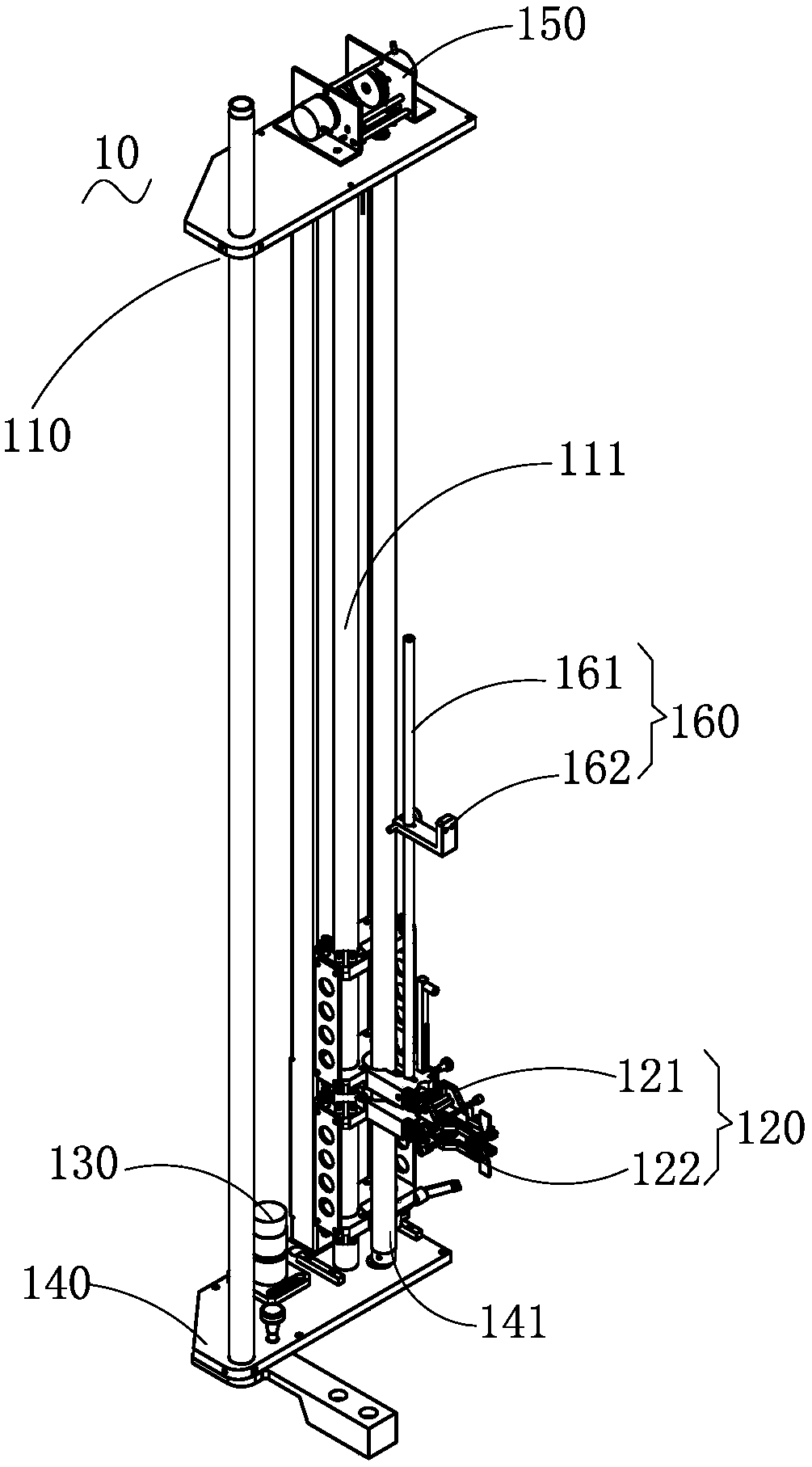

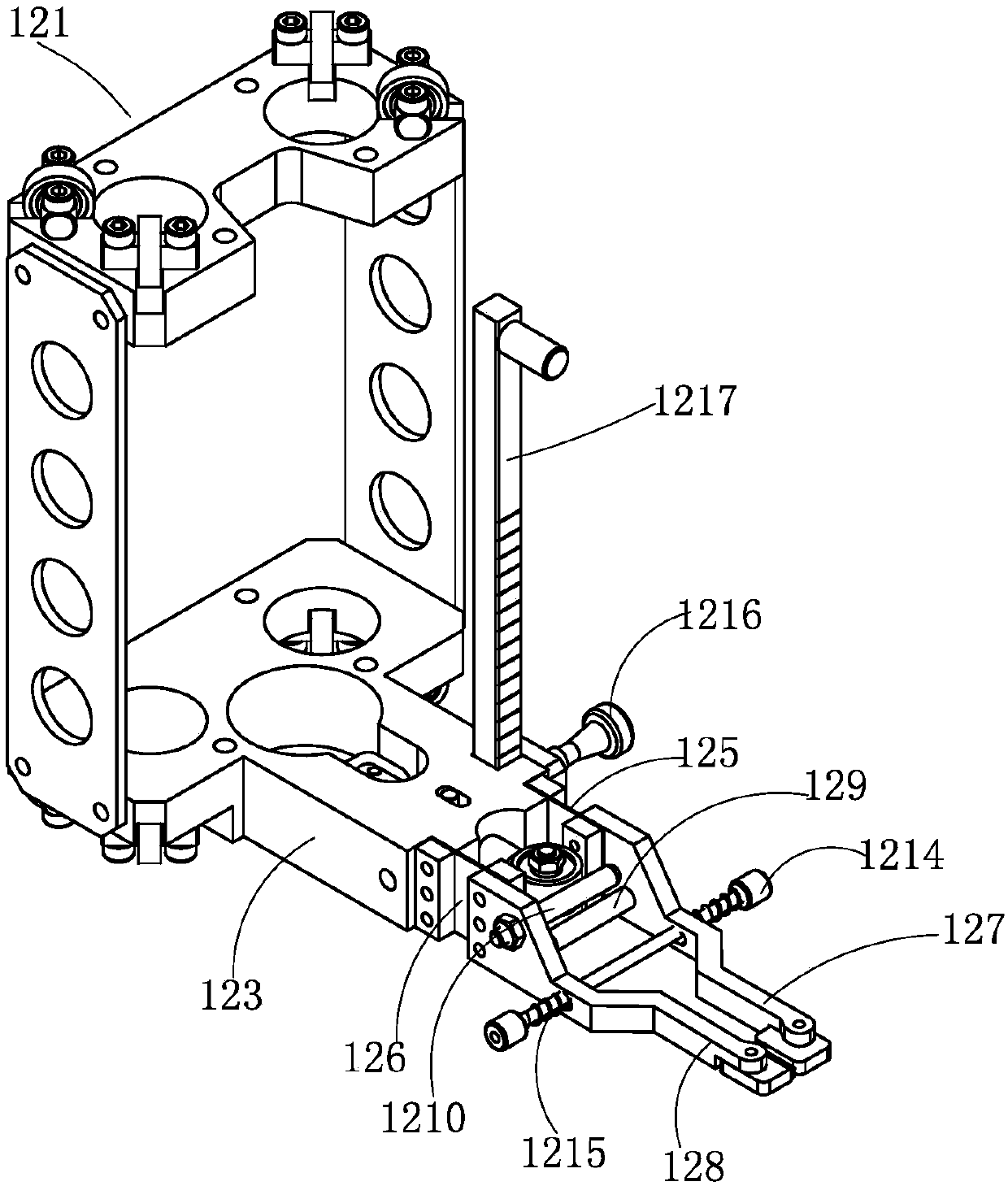

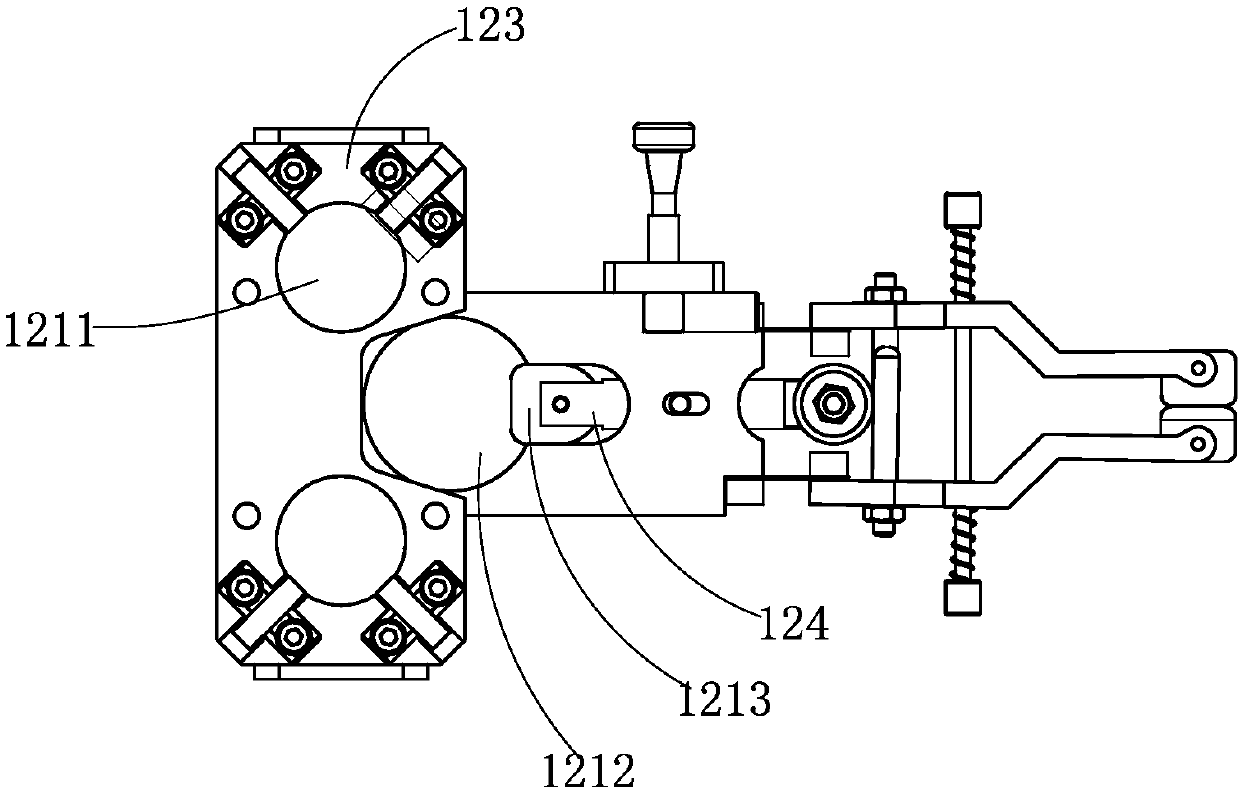

[0029] See attached figure 1 , which is a structural schematic diagram of a semi-automatic punctuation extensometer 10 of an embodiment, wherein figure 1 The specimen is included in , but only to clearly show the clamping position of the specimen, and does not mean that the equipment itself contains the specimen.

[0030] The semi-automatic marking extensometer 10 includes: a frame 110 , a clip device 120 , a motor 130 , a transmission device 140 , an extension sensing device 150 , a control device (not shown in the figure) and a return device 160 .

[0031] The frame 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com