Novel textile cart

A trolley, a new type of technology, applied in the direction of trolleys, multi-axis trolleys, motor vehicles, etc., can solve the problems of handling a small part, reduce labor intensity, and low work efficiency, and achieve simple structure, reduce transportation costs, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

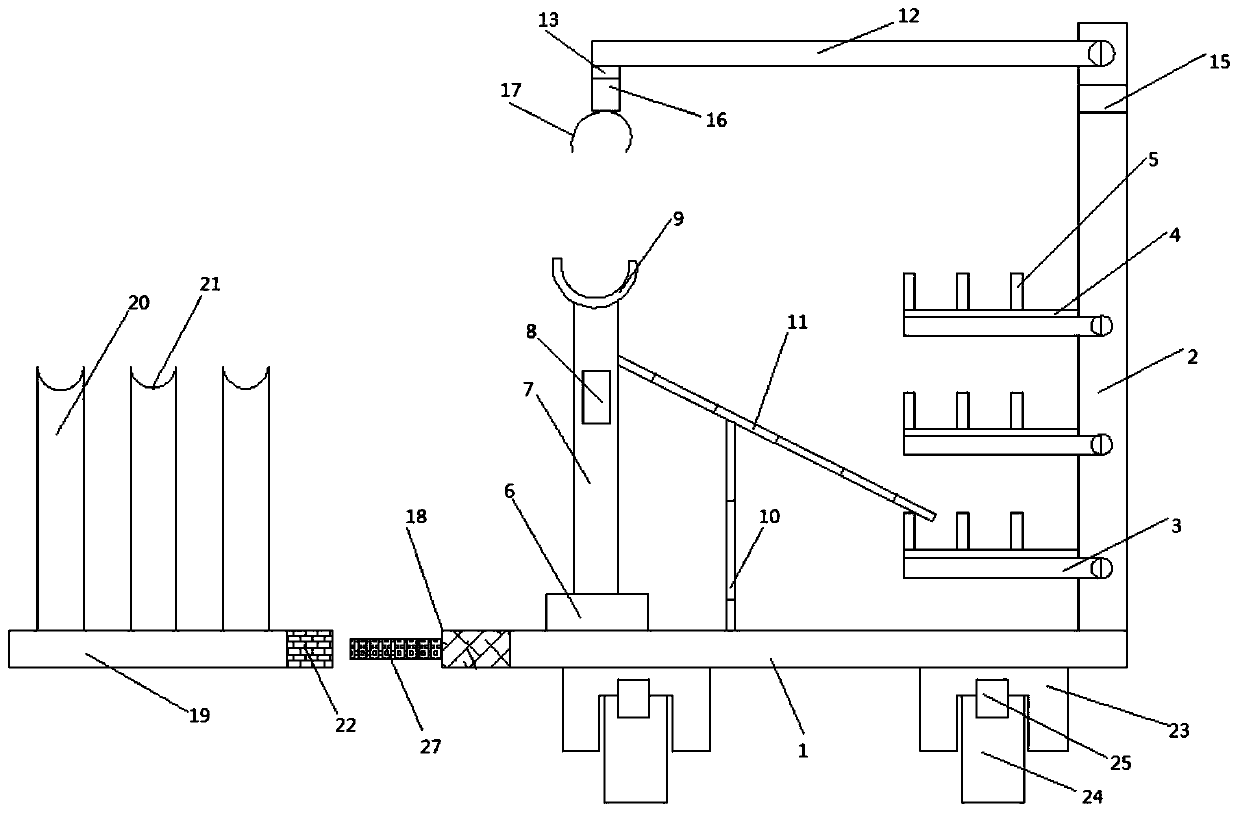

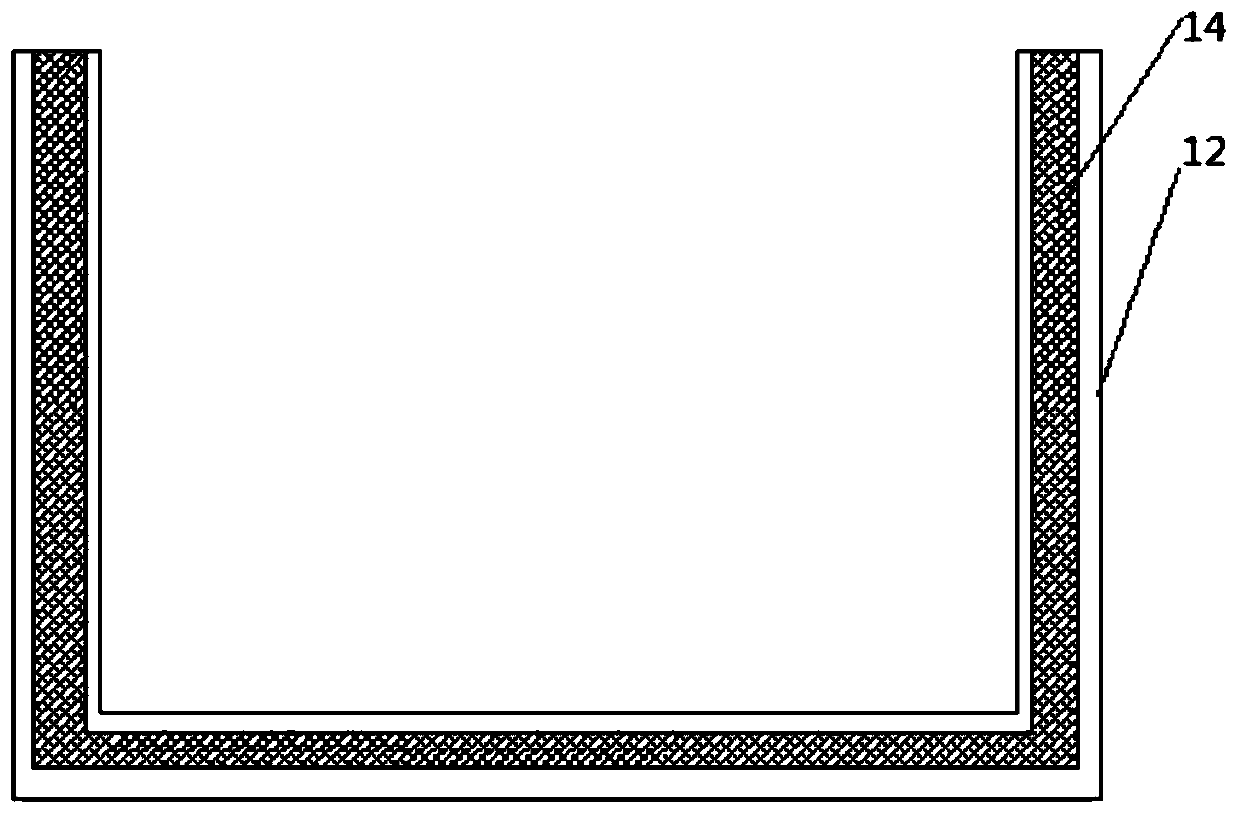

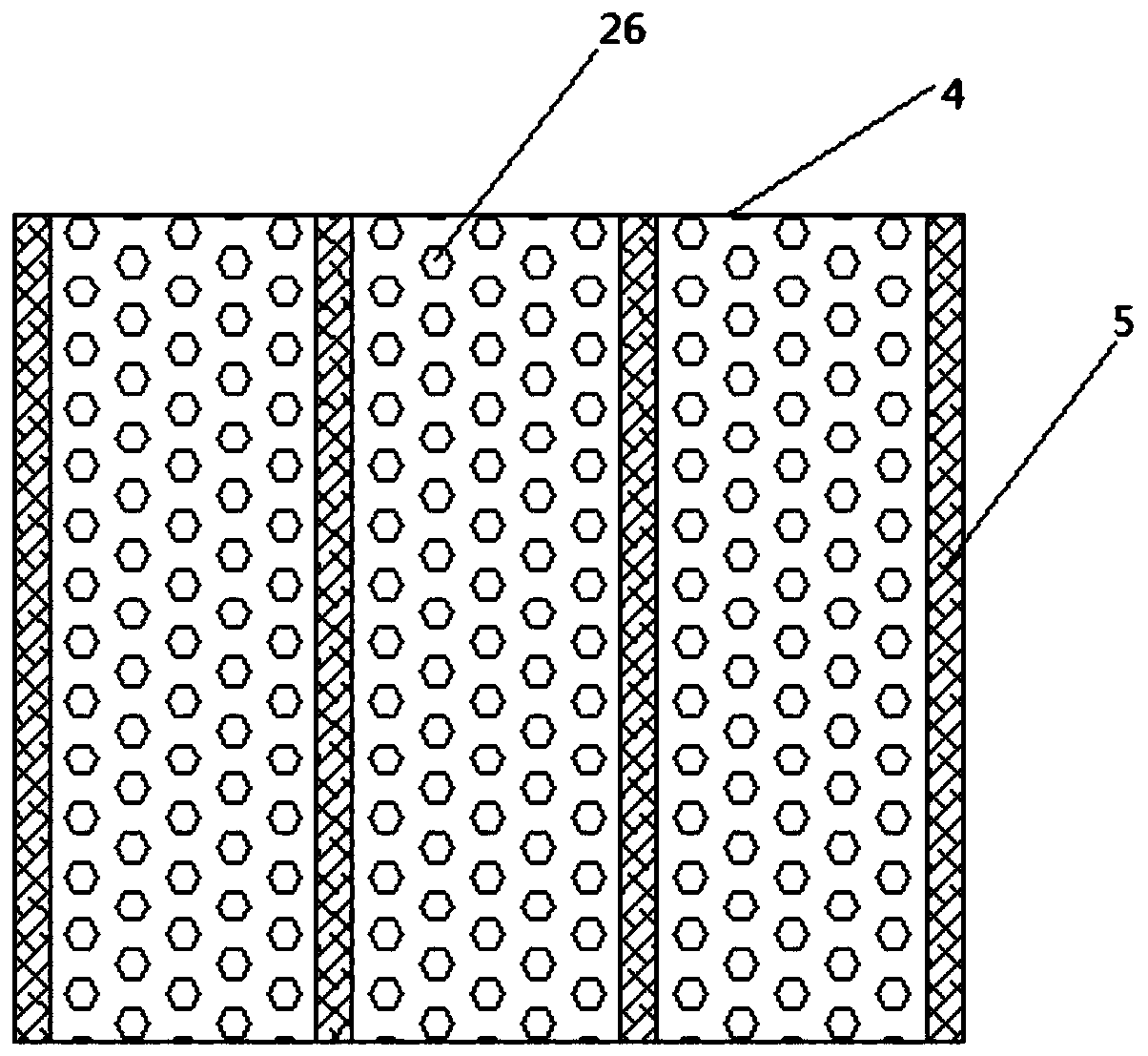

[0015] Refer to attached figure 1 , the present invention provides a novel textile cart, comprising a car body, a bottom plate 1 is provided at the bottom of the car body, a rolling device is provided below the bottom plate 1, two mutually parallel pillars 2 are vertically provided on one side of the bottom plate, Both sides of the two pillars 2 are provided with supporting rollers 3, and the supporting rollers 2 are provided with threaded holes, and the supporting rollers 3 are provided with transparent circular holes corresponding to the threaded holes. The supporting rollers 3 and the supporting pillars 2 are connected to each other by bolts, and the idlers 3 of the two pillars 2 are provided with a metal plate 4, and the metal plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com