Preparation method of liquid crystal cell

A technology of liquid crystal cells and liquid crystal droplets, applied in optics, instruments, nonlinear optics, etc., can solve the problems of long alignment time, long alignment time, adverse effects on the display effect of liquid crystal display devices, etc., and achieve the effect of eliminating Mura.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

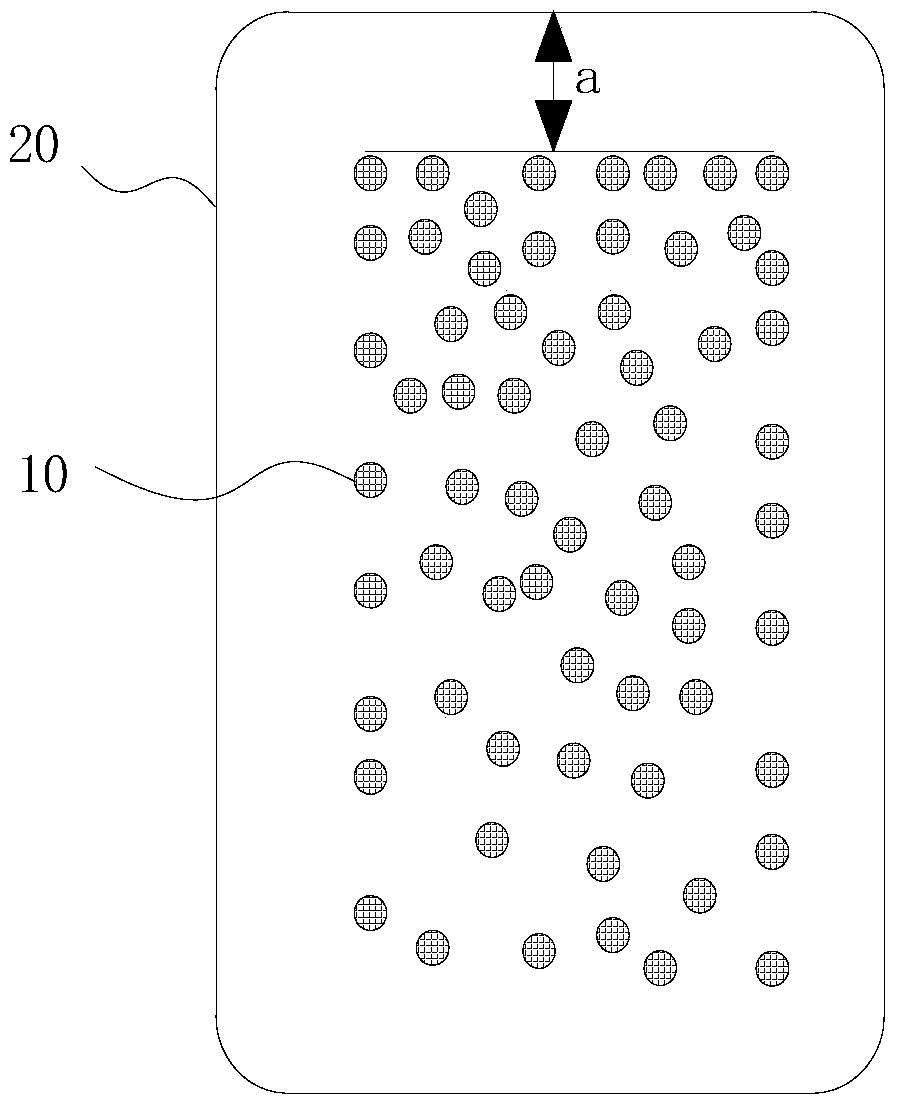

[0047] The technical solutions in the embodiments of the present invention will be clearly described below with reference to the drawings in the embodiments of the present invention.

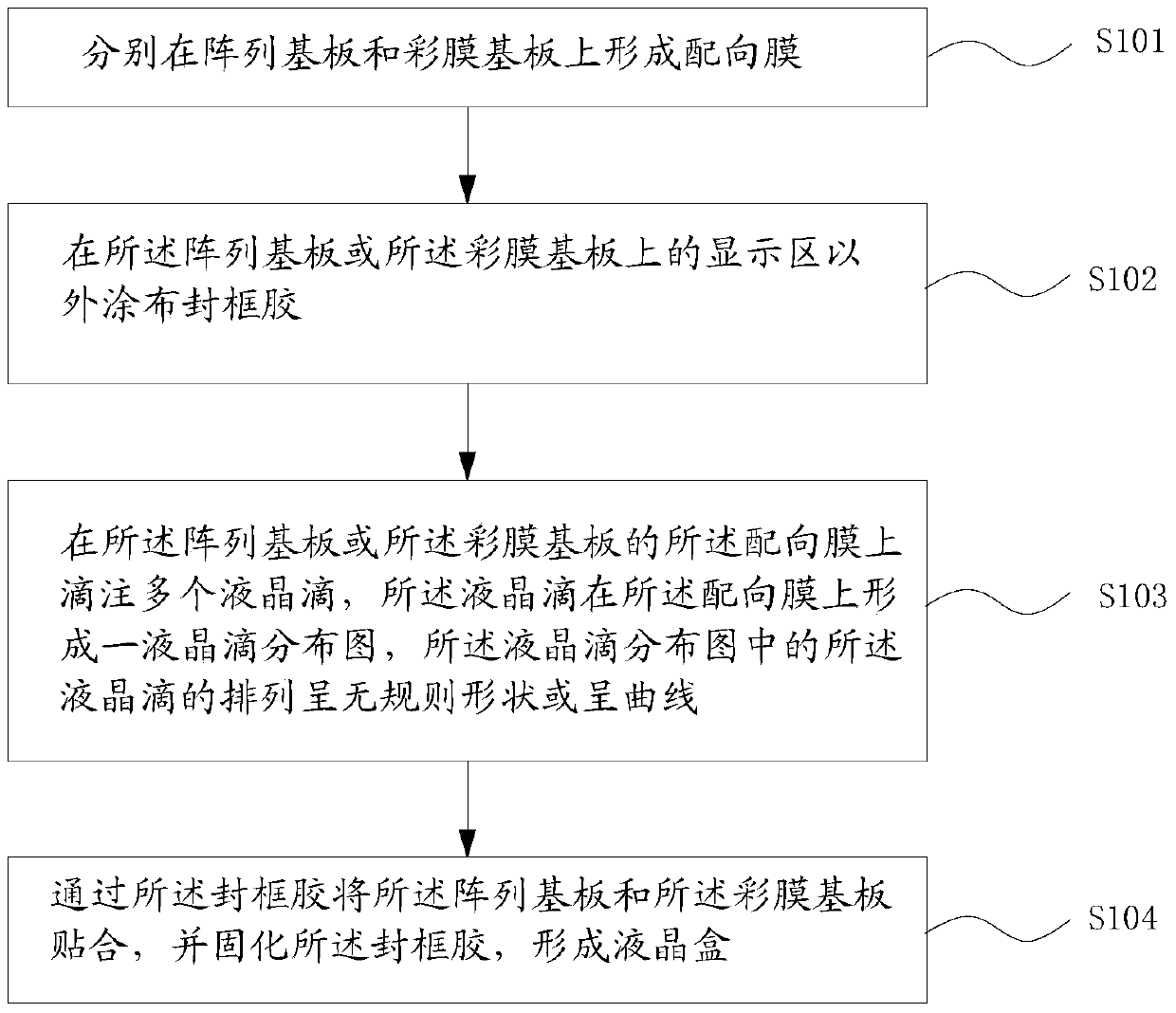

[0048] see figure 2 , figure 2 It is a flow chart of the liquid crystal cell preparation method in the first embodiment of the present invention. An embodiment of the present invention provides a method for preparing a liquid crystal cell, including steps S101 , S102 , S103 and S104 , which are specifically described as follows.

[0049] S101, forming an alignment film on the array substrate and the color filter substrate respectively, specifically:

[0050] In one embodiment of the present invention, the polyamic acid solution is coated on the array substrate and the color filter substrate respectively, and then the array substrate and the color filter coated with the polyamic acid solution are The substrate is pre-baked at a temperature range of 90°C to 115°C for 12 to 18 minutes, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com