Automobile light knob switch elastic sheet contact automatic assembling method

一种旋钮开关、弹片触点的技术,应用在电开关、电气元件、电路等方向,能够解决不能装配多种不同规格的铆钉、达不到高效率、银点不易摆放等问题,达到调试与维修方便、节约人工费、合格率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

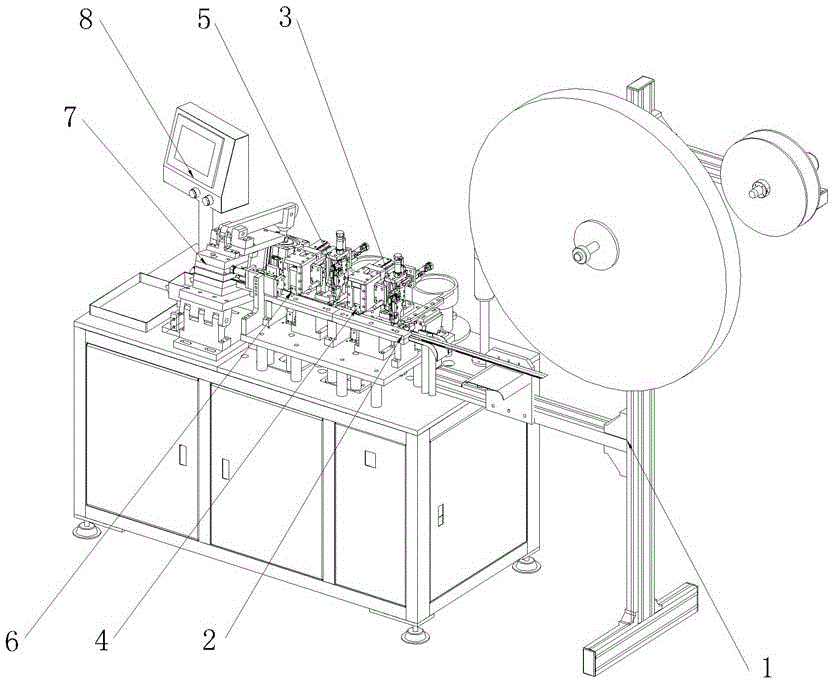

[0038] Embodiment: The overall structure diagram of the automatic assembly line of the shrapnel contact of the car light knob switch in this embodiment is as follows figure 1 shown, including sequentially mounted on the rack:

[0039] Automatic feeding station 1, used for feeding and positioning switch shrapnel strips;

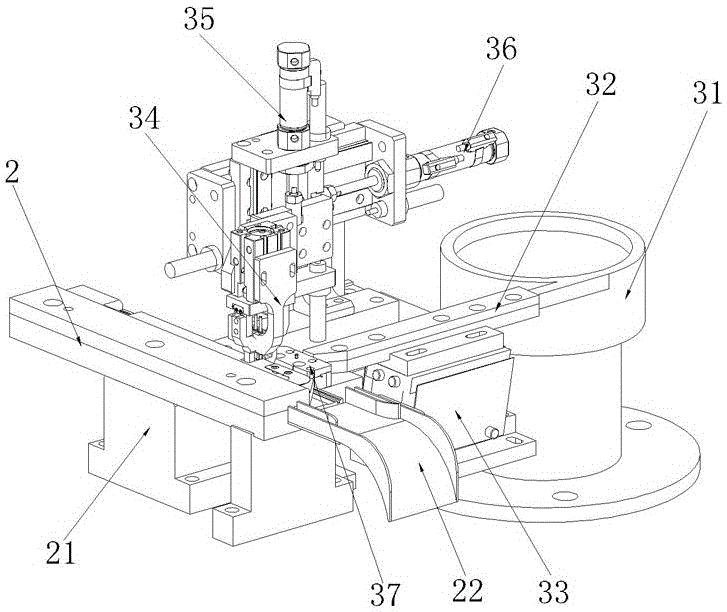

[0040] The guide runner 2, on one side of the guide runner 2, there are successively installed silver dot station 3, riveting silver dot station 4, copper dot station 5 and riveting copper dot station 6 for assembling contacts, and the guide runner 2 The end section is also equipped with a detection device and a pulling belt mechanism;

[0041] Automatic discharge station 7 for separating and outputting products;

[0042] A controller 8 is also installed on the frame, and the controller 8 is connected to the detection device and the actuators of the above-mentioned stations.

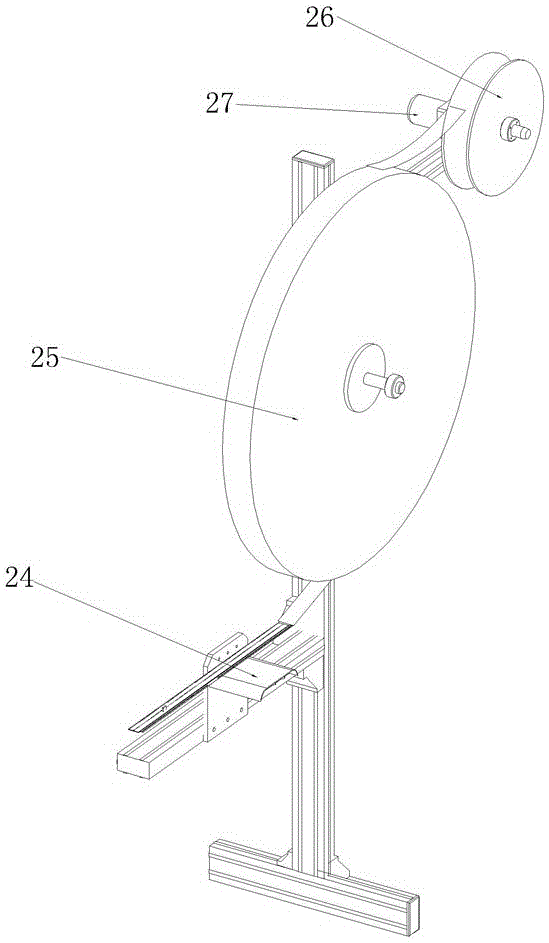

[0043] Such as figure 2 As shown, the automatic feeding station includes a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com