Self-correction starting method based on rotor position detection for brushless motor

A rotor position, brushless motor technology, applied in the direction of electronic commutator, starting device, etc., can solve problems such as failure to start, wrong determination of rotor position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

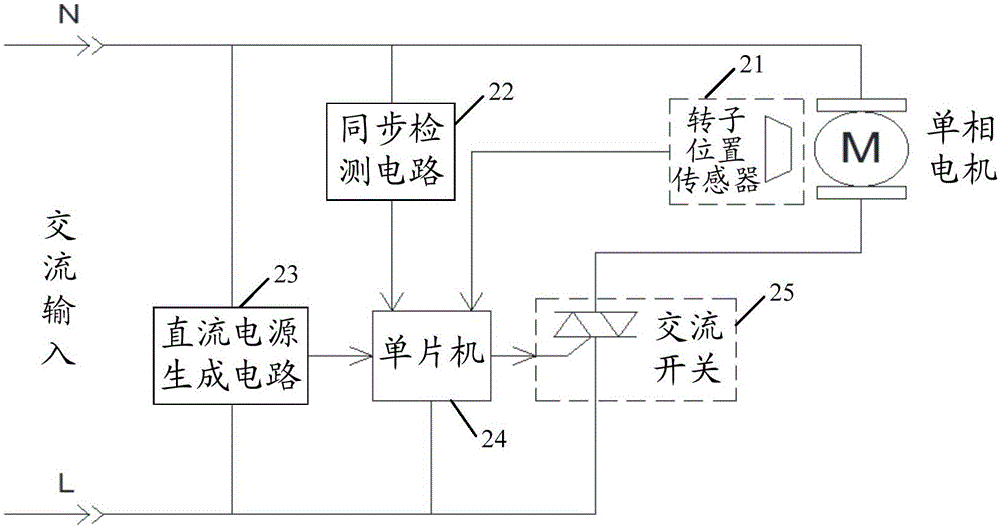

[0039] The present invention will now be described in detail with reference to the accompanying drawings. The present invention is described by taking a single-phase brushless motor as an example to make the principle of the present invention easy to understand, but the description by taking a single-phase brushless motor as an example does not limit the practical application scope of the present invention to single-phase brushless motors. For motors, the method of the present invention is also applicable to multi-phase brushless motors, and multi-phase brushless motors are also within the scope of the present invention.

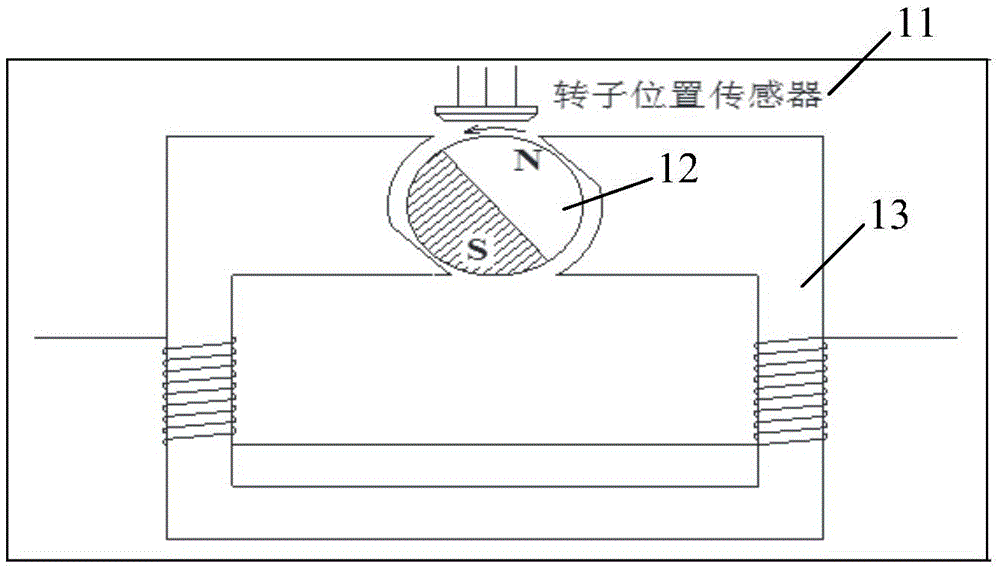

[0040] figure 1 A block diagram showing the internal structure of a single-phase brushless motor. Such as figure 1 As shown, the single-phase brushless motor generally consists of an electronic control system (not shown), a rotor position sensor 11 , a rotor 12 and a stator 13 in structure.

[0041] The rotor position sensor 11 can usually choose a magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com