A kind of static pressure type Moringa seed shelling machine and shelling method

A Moringa seed and shelling machine technology, which is applied in the field of Moringa seed shelling, can solve the problems of ineffective control of broken particle rate, poor quality of shelling operation, high processing cost, etc., and achieves simple structure, low processing cost and high cost. The effect of shelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

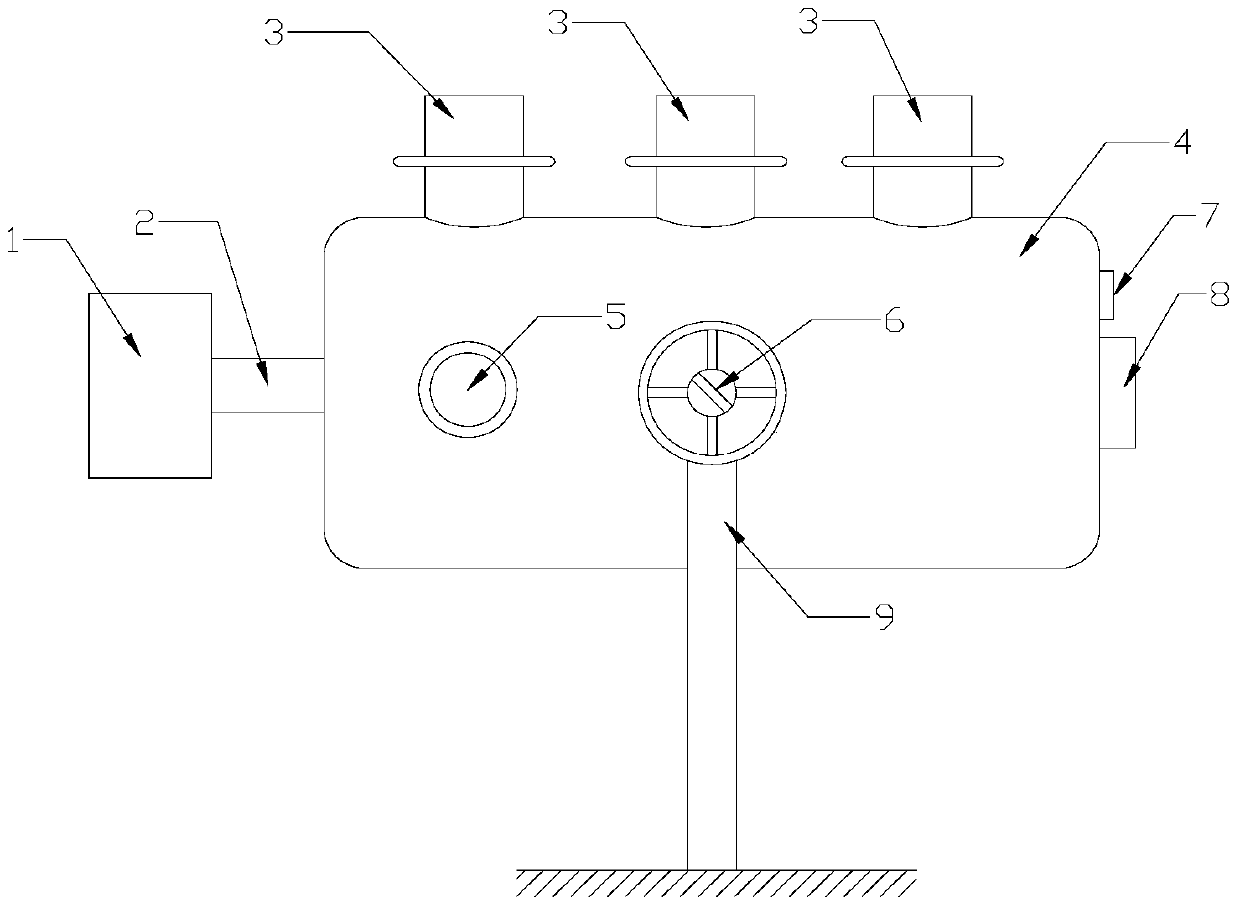

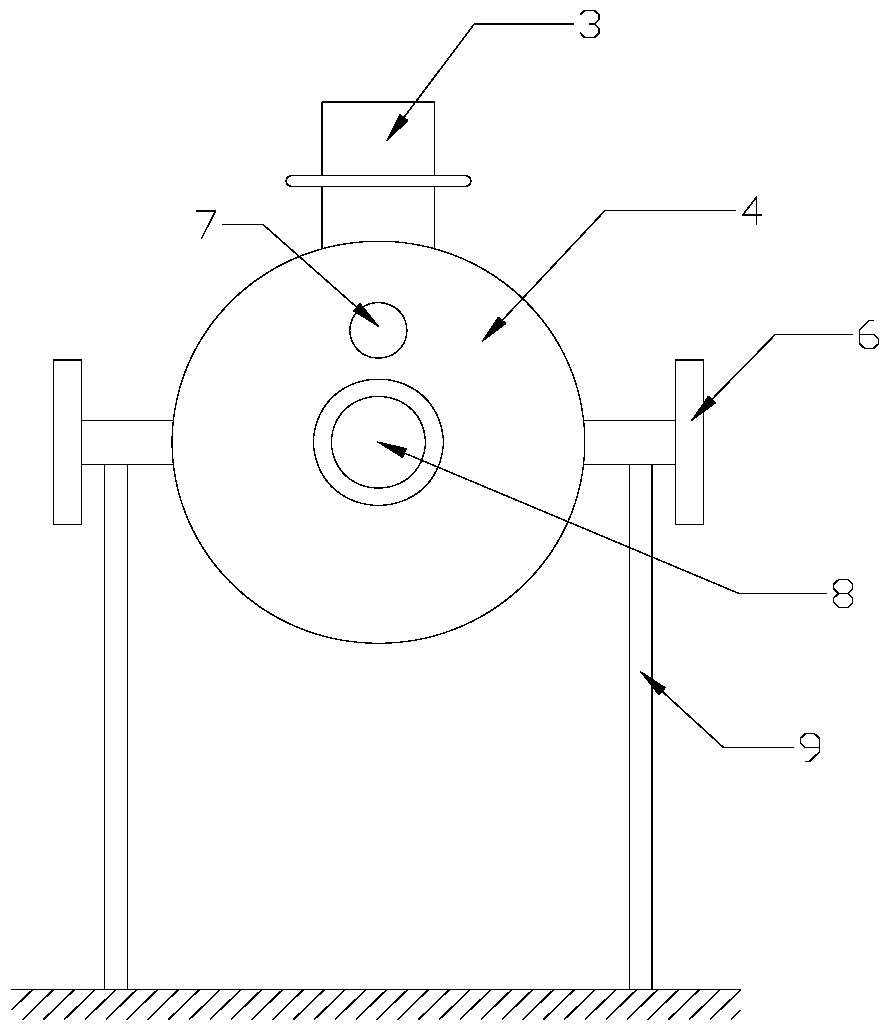

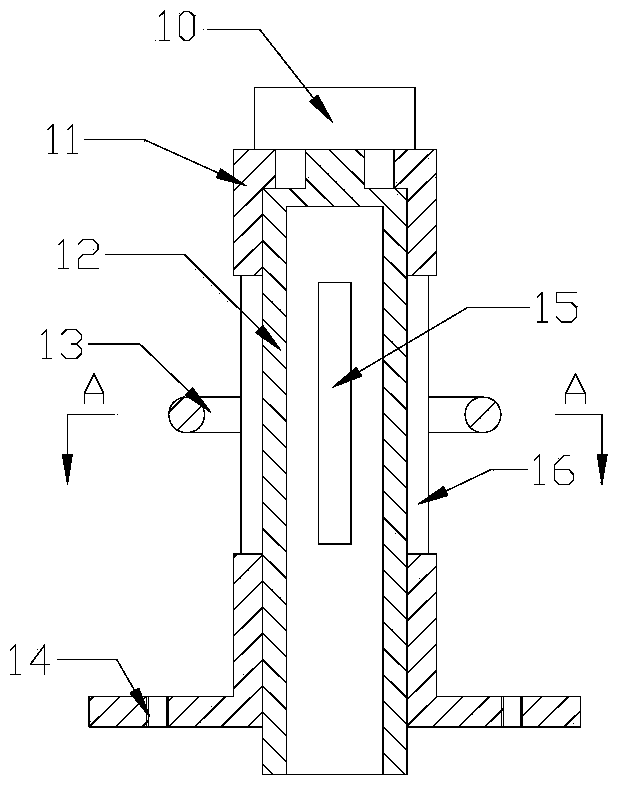

[0031] like figure 1 , figure 2 As shown, a static pressure Moringa seed shelling machine includes: a pressurizing mechanism, an exhaust valve, a high-pressure gas tank, an overpressure protection valve, a steering handle, a pressure gauge, a sealing valve, and a support frame.

[0032] The pressurizing mechanism and the exhaust valve are all connected with the high-pressure gas tank, and the high-pressure gas tank for loading Moringa seeds is installed on the support frame. When the support frame supports the high-pressure gas tank, the height of the high-pressure gas tank to the ground It should be greater than half the length of the high pressure gas tank. The pressurizing mechanism includes an air compressor and a channel, the air compressor is connected to the channel, the channel communicates with the high-pressure gas tank, and the air compressor compresses the air to pressurize the high-pressure gas tank through the channel. Both the overpressure protection valve an...

Embodiment 2

[0036] This embodiment is the same as Embodiment 1 except the following technical features.

[0037] In this embodiment, the high-pressure gas tank in Embodiment 1 is replaced by a sealed container with the same function, and the exhaust valve in Embodiment 1 is replaced by a pressure relief mechanism with the same function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com