A miniature electric sprayer

An electric sprayer and miniature technology, which can be applied to spray devices, single handheld devices, etc., can solve the problems of large frictional resistance, waste of energy, short battery life, etc., and achieve reduced contact area, convenient and fast operation, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

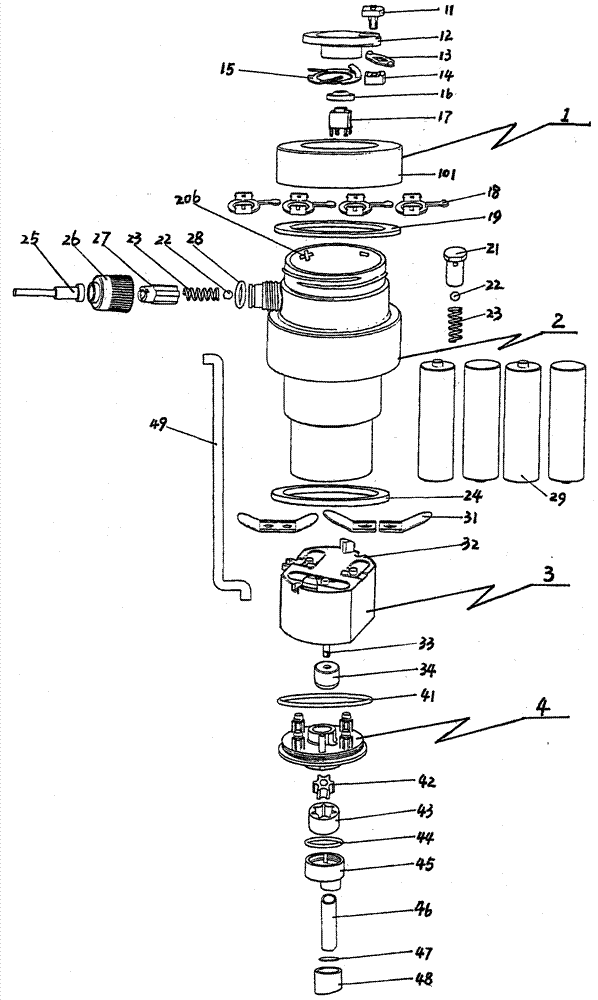

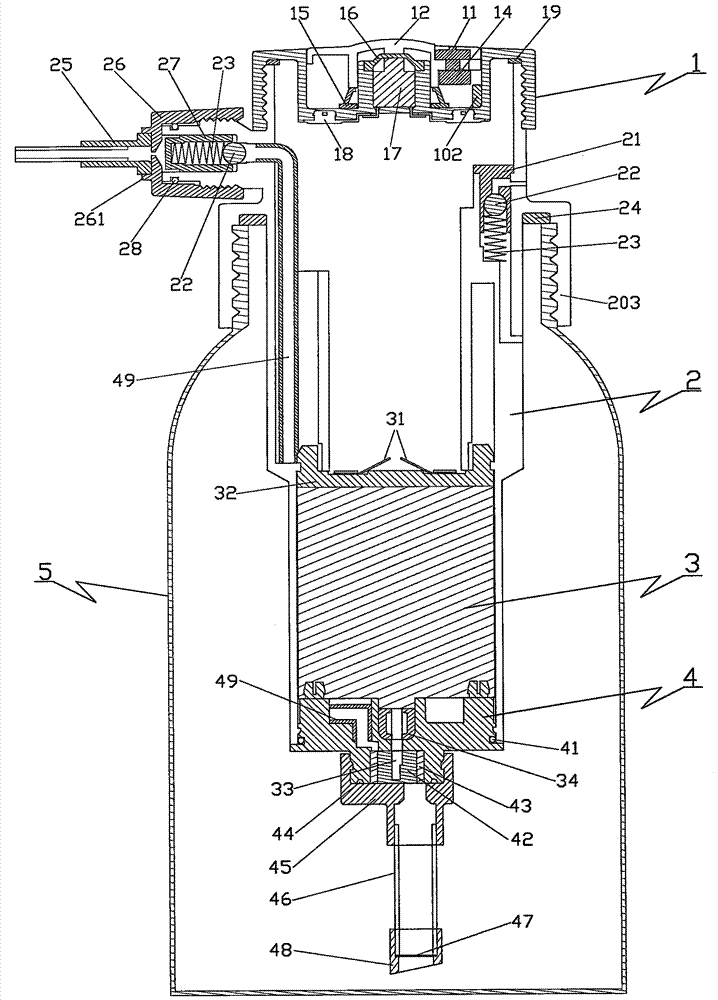

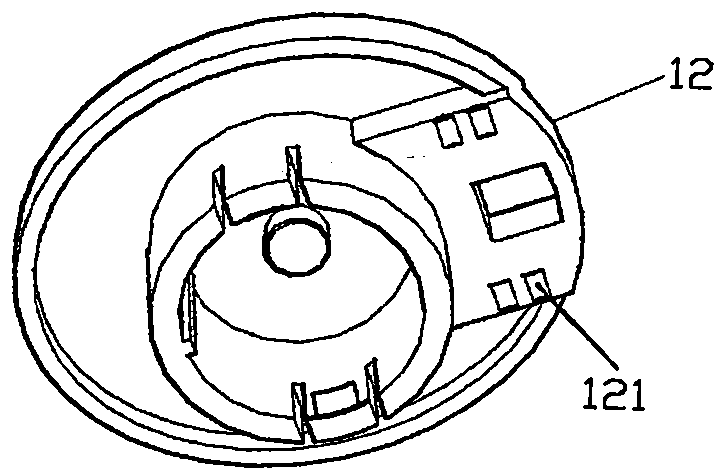

[0029] The main structural features, working principle and use of the miniature electric sprayer will be further described in conjunction with the accompanying drawings. please see figure 1 with figure 2 , a miniature electric sprayer, its structure from top to bottom, including battery box cover 1, main body 2, motor 3 and pump body 4 four parts, motor 3 and pump body 4 are located in the lower part of the main body 2. The battery case cover 1 is equipped with a button 12, an anti-maloperation switch assembly, a power switch 17, a battery connection piece 18, and the battery case cover 1 and the main body 2 are screwed or flipped. The main body 2 is cylindrical, and the inner cavity of the upper part of the main body 2 is a battery compartment 204 for placing a battery pack 29. There is a nozzle 202 on one side of the upper part of the main body 2, and a nozzle assembly and a nozzle cover 26 are installed on the nozzle 202. A waterproof sealing ring 41 is provided between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com