Double-shaft milling machine

A biaxial milling machine and bed head box technology, which is applied in the direction of milling machines, milling machine equipment, milling machine equipment details, etc., can solve the problems of large dimensional accuracy and position accuracy errors of dovetail slots or dovetail strips, and achieve high dimensional accuracy and position accuracy, Guaranteeing quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing:

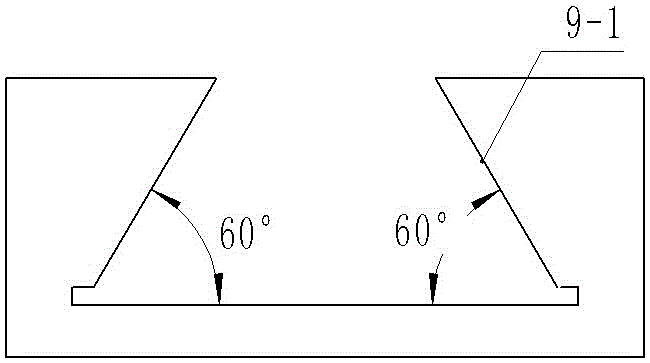

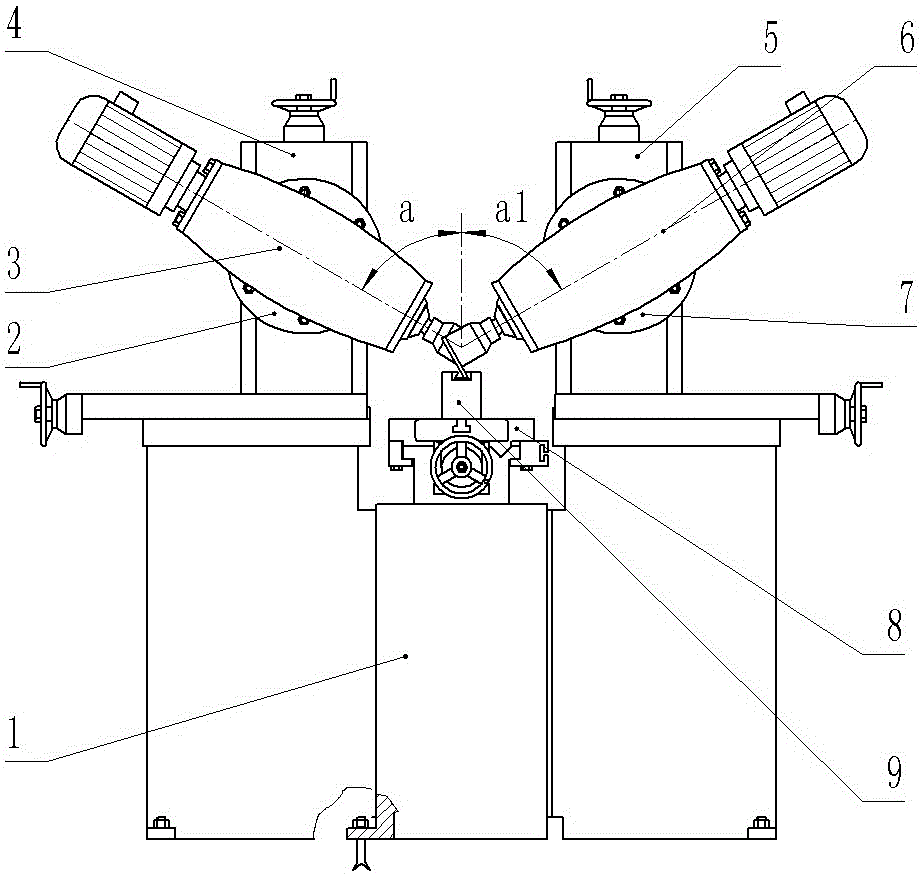

[0010] Such as figure 1 The shown two-axis milling machine includes a body 1, on which a headboard box 4 is housed, and the headboard box 4 is installed on the left side of the body 1; Vertical power head 3 is also equipped with a pair of bedside boxes 5 on the fuselage 1, and the auxiliary bedside box 5 is contained on the right side of the fuselage 1, and the auxiliary bedside box 5 is equipped with vertical Type auxiliary power head 6; workbench 8 with clamping parts between bedside box 4 and auxiliary bedside box 5; vertical power head 3 and vertical auxiliary power head 6 are vertically staggered, vertical auxiliary power Head 6 is positioned at vertical power head 3 front.

[0011] When working, the dovetail groove blank to be processed is clamped on the workbench 8 by the clamping tool; the milling cutter is respectively installed on the tool holder of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com