Postponing mold for cutting of hollow rubber hose

A rubber hose and positioning mold technology, applied in metal processing and other directions, can solve the problems of reducing bonding strength, hose deformation, large angle error, etc., to achieve smooth cutting surface, ensure cutting angle, and ensure bonding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

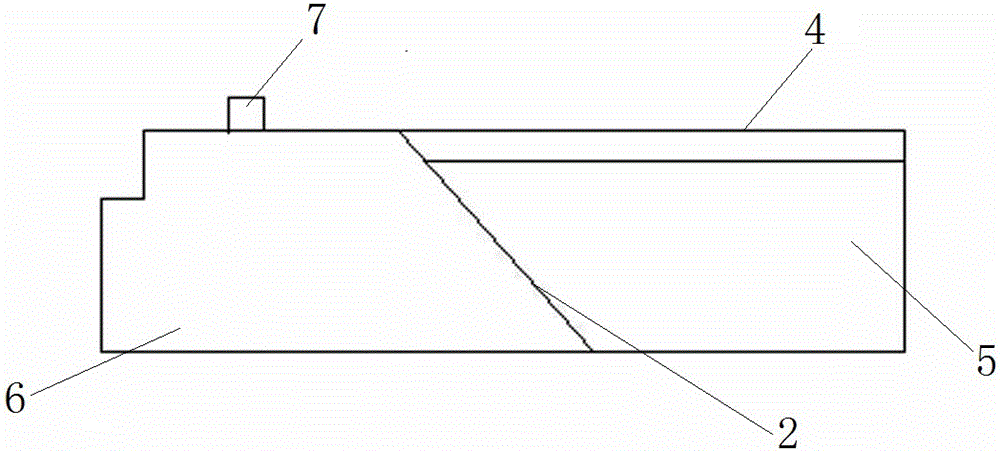

[0019] like Figure 1-5 As shown, a hollow rubber hose cutting and positioning mold, the upper mold 1 with the beveled surface II3 and the lower mold 4 with the beveled surface I2 are movably connected;

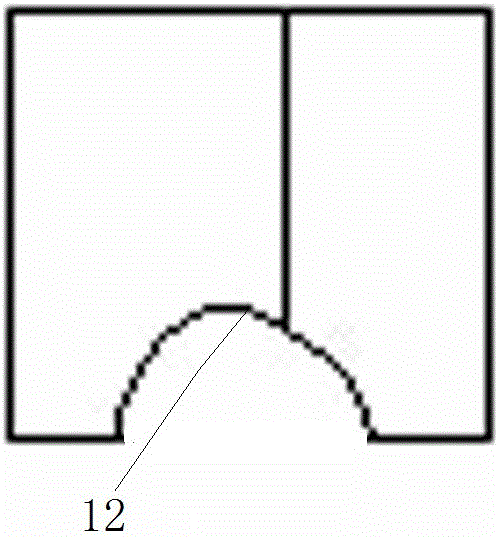

[0020] The lower mold 4 is composed of a positioning plate I5 and a guide block I6 with a beveled surface I2, which are fixedly connected. The heights of the positioning plate I5 and the guide block I6 are equal, and a The positioning pin 7 and the upper end surface of the guide block I6 are provided with an arc-shaped groove I8, and the length of the arc-shaped groove I8 is equal to the length of the upper end surface of the guide block I6;

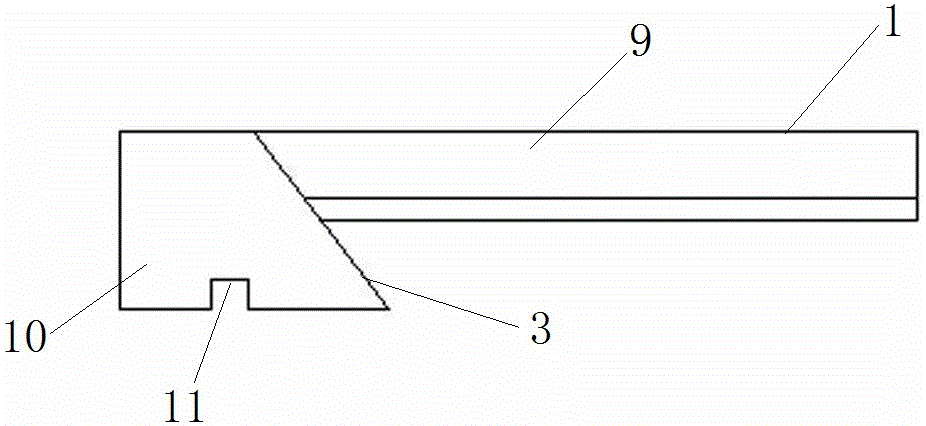

[0021] The upper mold 1 is composed of positioning plate II9 and guide block II10 with inclined plane II3 fixedly connected, positioning plate I5 corresponds to positioning plate II9, inclined plane I2 corresponds to inclined plane II3, positioning plate II9 and guide block II10 The lower end surface of the guide block II10 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com