Building block and building material cutting fixing device and implementation method

A technology of fixing devices and positioning devices, which is applied in the direction of stone processing equipment, working accessories, manufacturing tools, etc., can solve the problems of low efficiency, flying debris, and difficulty in controlling the cutting size of building materials by hand-cutting blocks, so as to solve the problems of low efficiency, Effect of improving efficiency and precision, improving work efficiency and operation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

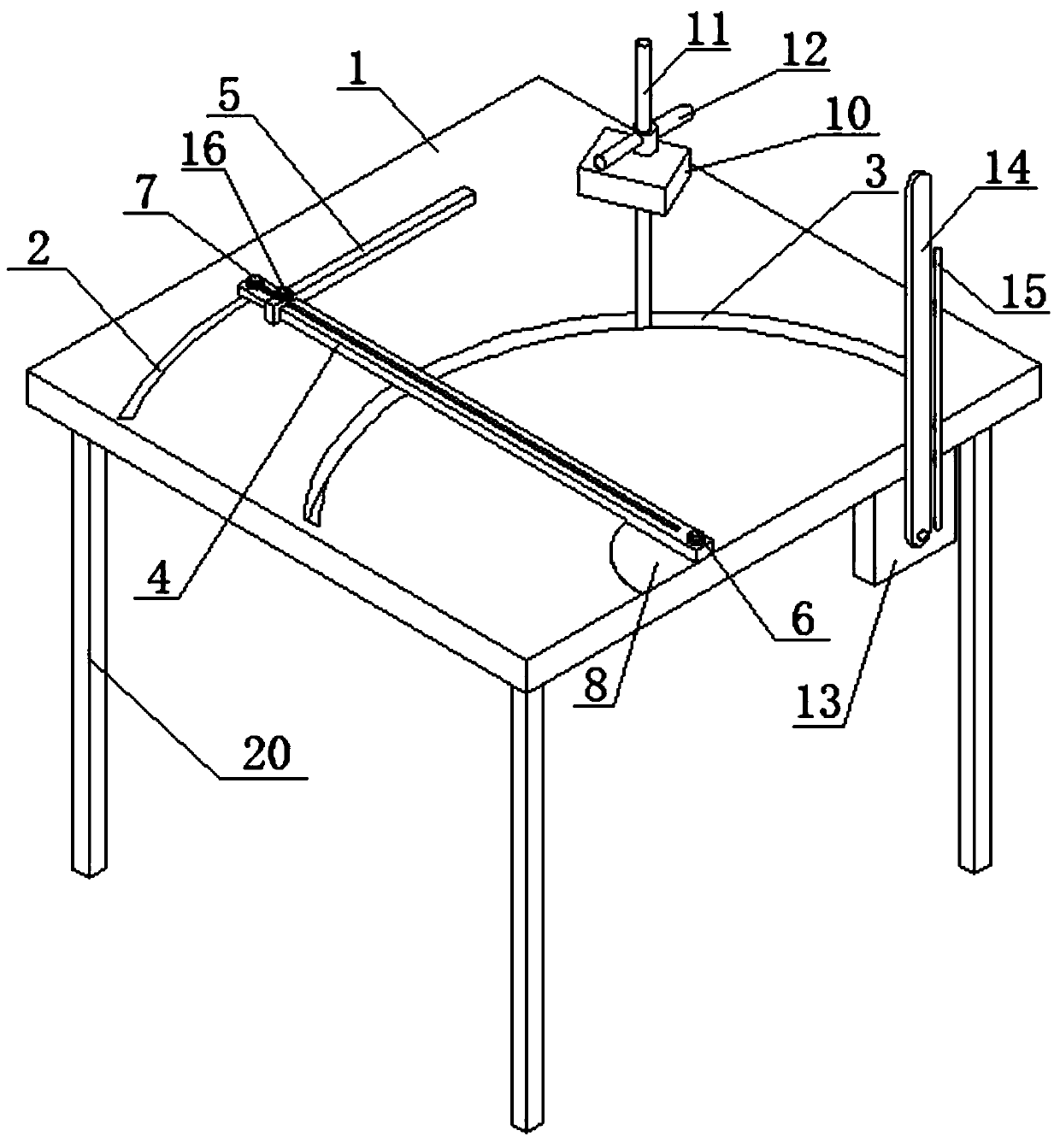

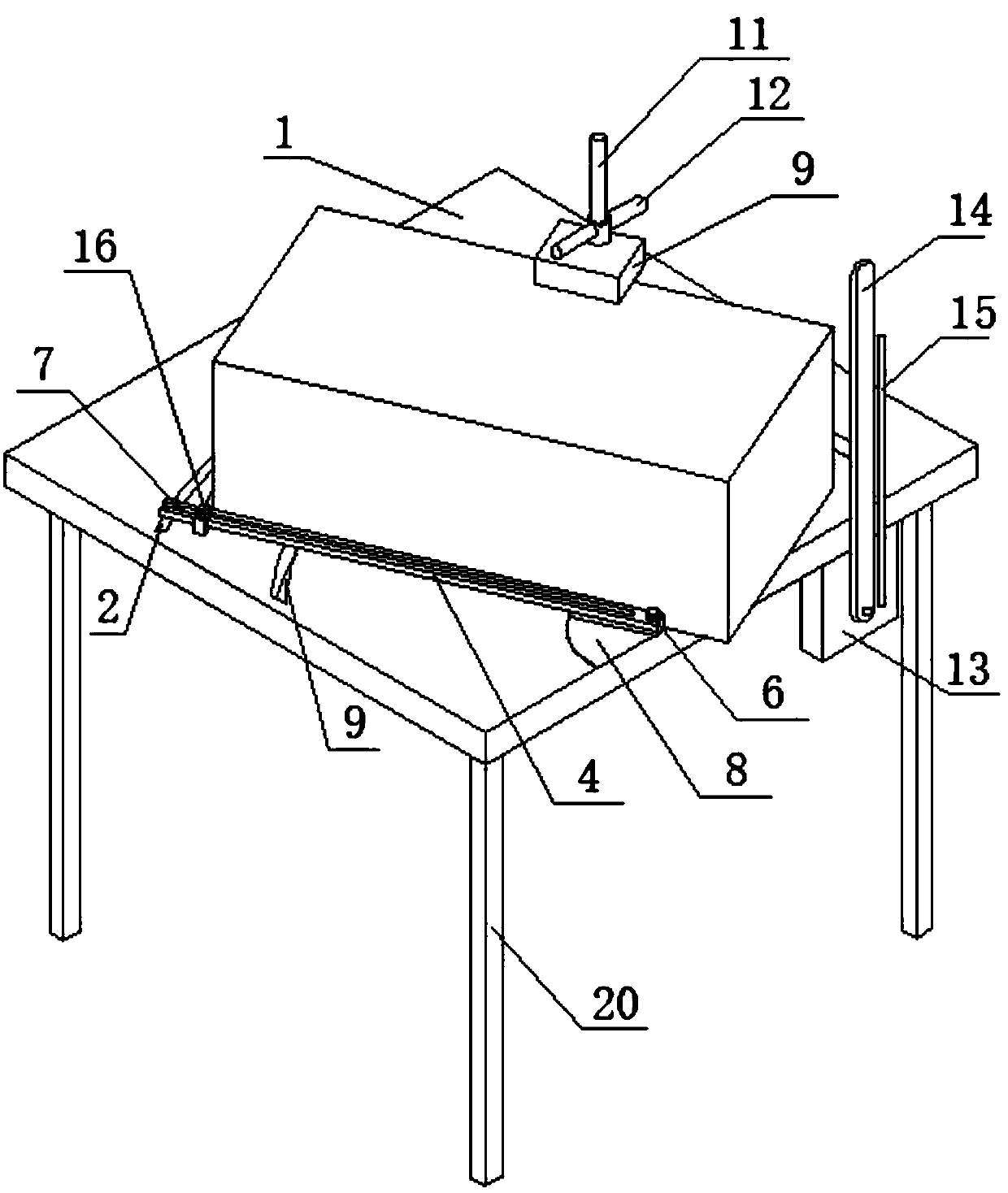

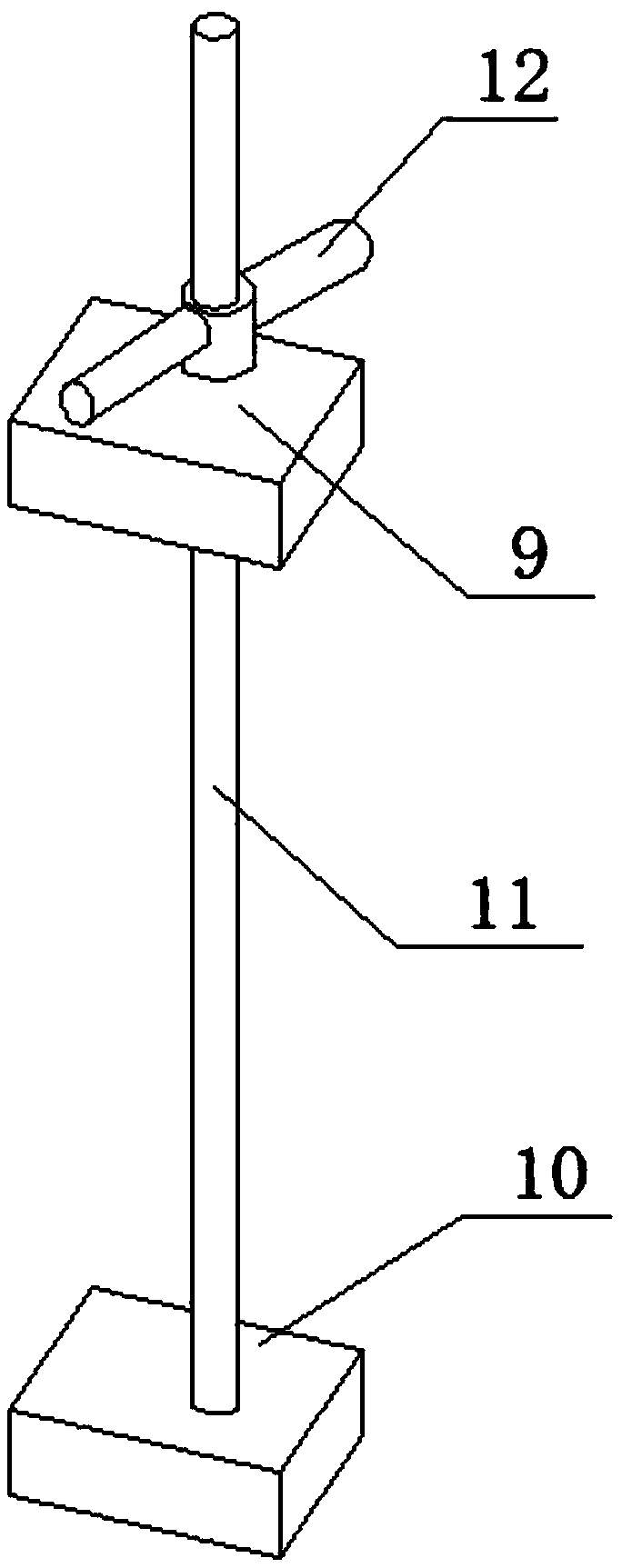

[0033] Such as Figure 1 to Figure 3 The shown block building material cutting and fixing device includes an operating platform 1, and is characterized in that it also includes a positioning device, a clamping device and a cutting auxiliary device,

[0034] The upper surface of the operating platform 1 is provided with a ruler chute 2 and a screw chute 3, and the lower end of one side of the operating platform 1 is fixedly connected with a cutter guide rail 17;

[0035] The positioning device includes a ruler 4, the upper end surface of the ruler 4 is provided with a scale mark, the upper surface of the ruler 4 is also provided with a groove rail, and the outside of the ruler 4 is provided with a clip 5, and the clip 5 and the ruler 4 is connected with the surface of one end connected with the first fastening bolt 16, the bottom end of the first fastening bolt 7 runs through the clip 5 and extends into the groove rail of the ruler 4; the two ends of the ruler 4 are respectivel...

Embodiment 2

[0040] Such as Figure 1 to Figure 3 The implementation method of a block building material cutting and fixing device shown is:

[0041]Before use, ensure that the ruler 4 of the cutting fixture is perpendicular to the side where the electric cutter 13 is arranged on the operating platform 1, and the reading on the angle plate 8 on the side of the ruler 4 is 0°;

[0042] When in use: First, position and reinforce the cutting building materials: place one side of the cutting building materials in close contact with the ruler 4, and ensure that the first side of the cutting building materials is flush with the side of the operating platform 1; 5. Slide on the ruler 4 until it fits with the other side of the aforementioned side of the cutting building material, slide the clip 5 according to the scale mark on the ruler 4, and push the cutting building material to the operating platform 1. Set one of the electric cutters 13 On the side, when the moving distance meets the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com