New clutch rubber airbag inner tube cutting and pressing integrated equipment

A rubber airbag and clutch technology, applied in metal processing, etc., can solve the problems of airbag inflation and deflation efficiency, size, thickness unevenness, human body and environmental pollution, etc., to achieve semi-automatic and assembly line operations, stable and fast charging and discharging Air, improve the effect of pressing and bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

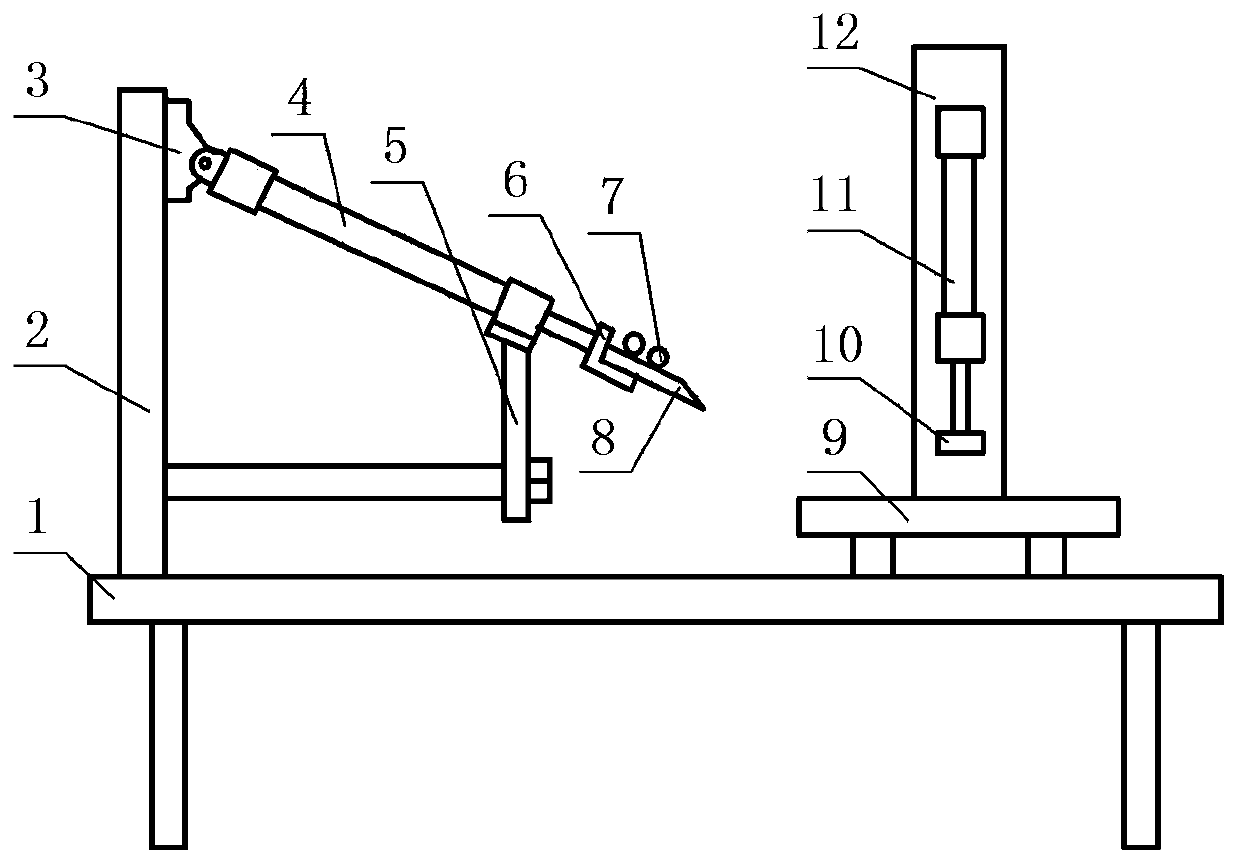

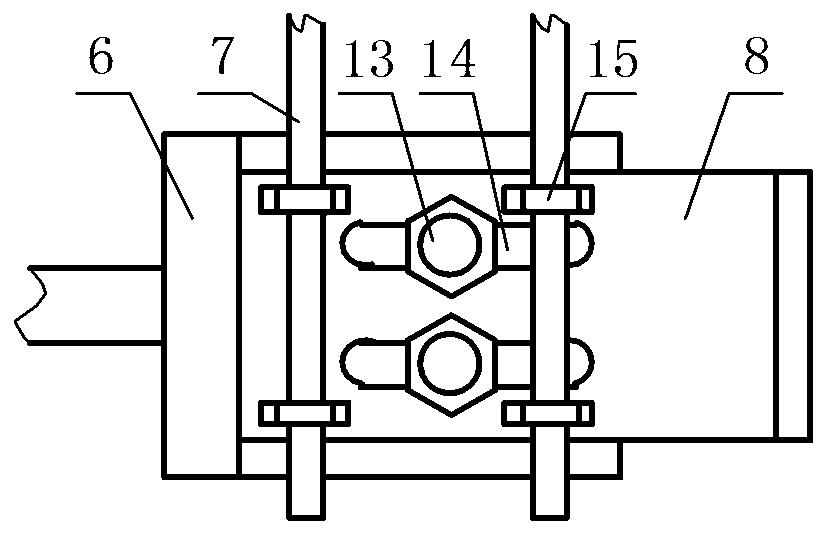

[0016] Example: see figure 1 with figure 2 , in the figure, 1-underframe, 2-tripod support frame, 3-hinge seat, 4-shear air cylinder, 5-adjusting plate, 6-fixing plate, 7-electric heating tube, 8-shear knife, 9 -backing plate, 10-pressing block, 11-pressing air cylinder, 12-stand, 13-connecting bolt, 14-long hole, 15-clip.

[0017] The new clutch rubber airbag inner tube cutting and pressing integrated equipment includes a chassis 1, the chassis 1 is composed of a panel and legs, wherein: one end of the panel is provided with a triangular support frame 2, and one side of the triangular support frame 2 passes through the hinged seat 3 It is rotationally connected with the rear end of the shearing air cylinder 4, the other side of the triangular support frame 2 is connected with the front end of the shearing air cylinder 4 through the adjustment plate 5, and the piston rod of the shearing air cylinder 4 is connected with the fixed plate 6, The fixed plate 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com