Equipment for cleaning up marginal materials of die-cutting paper products

A technology of scrap removal and paper products, applied in metal processing, transportation and packaging, conveyor objects, etc., can solve the problems of high labor cost, reduced production efficiency, low product transportation efficiency, etc., to improve the efficiency of unboxing, improve The effect of unboxing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

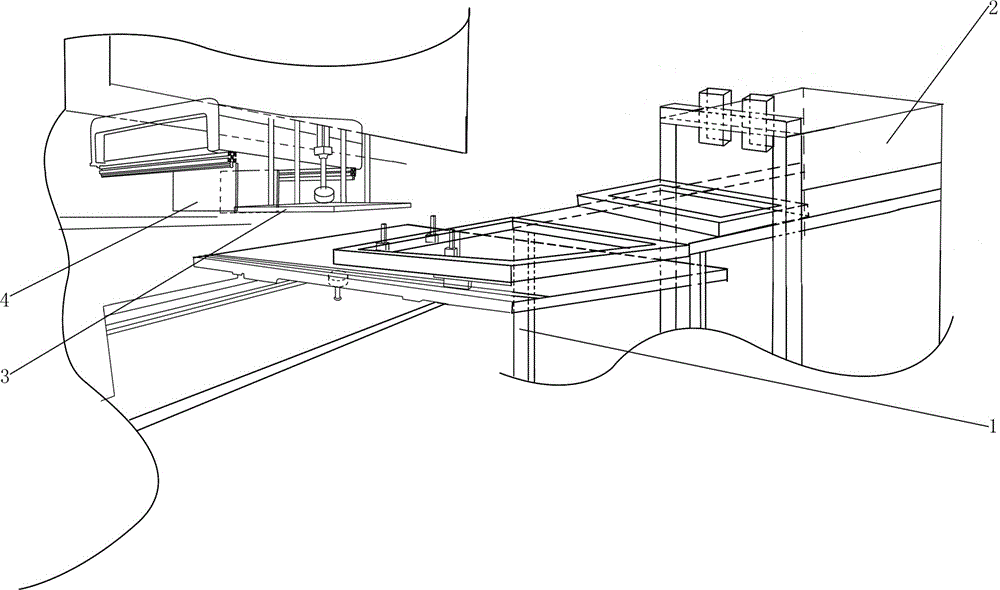

[0031] Such as figure 1 As shown, a die-cut paper product edge removal device includes a frame 1, a feeding mechanism 2, an edge removal mechanism 3 and a finished product removal mechanism 4.

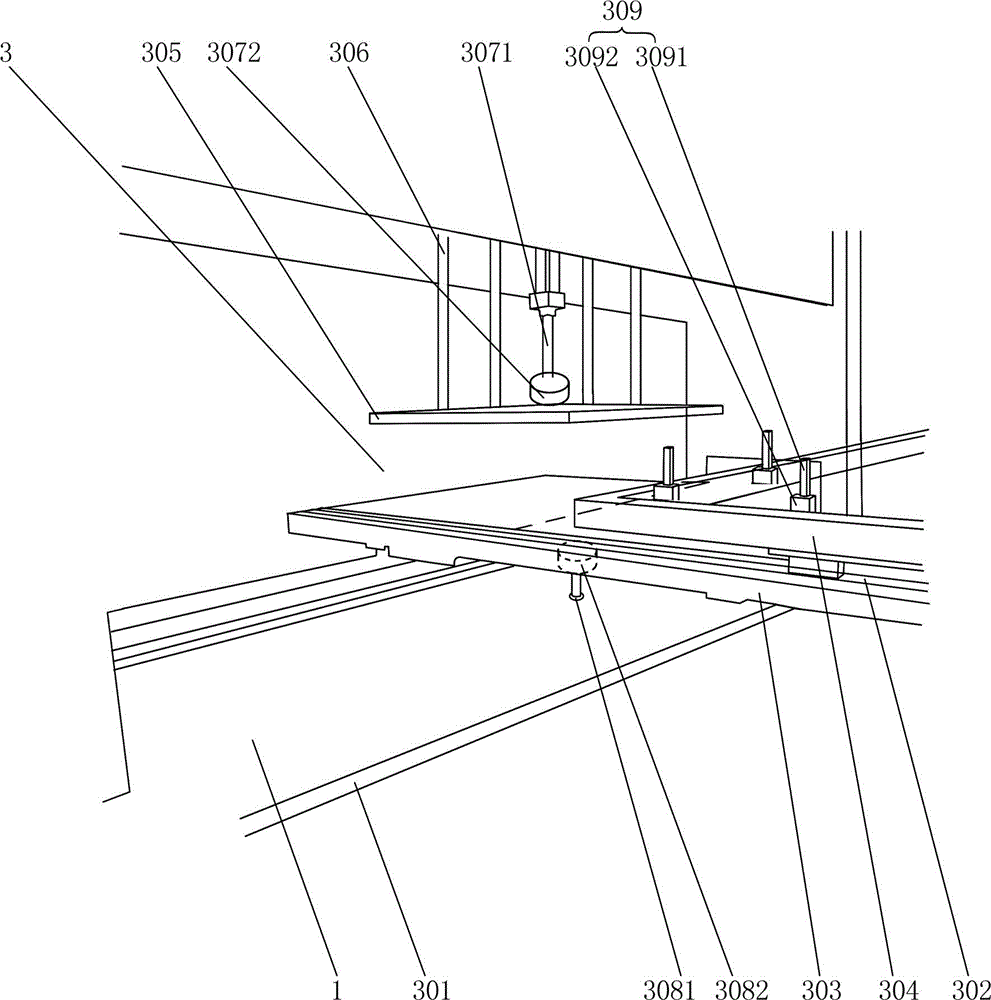

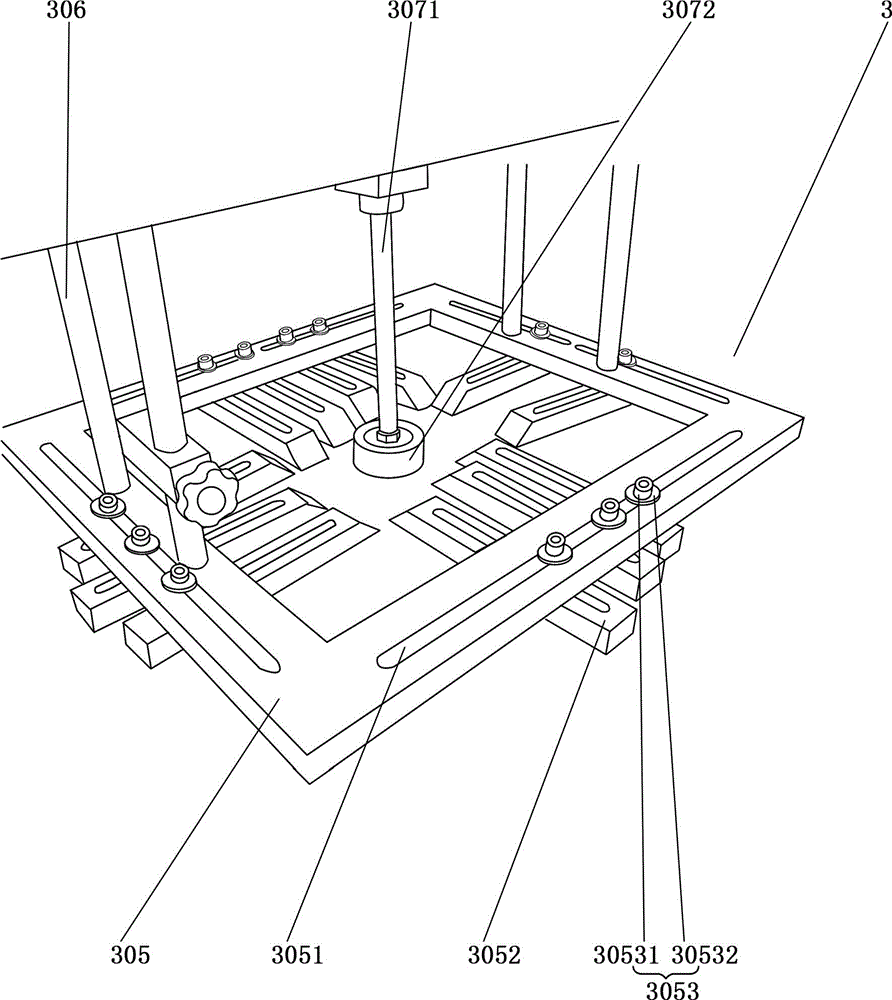

[0032] Such as figure 2 As shown, the edge removal mechanism 3 includes two x-guiding rails 301, two y-guiding rails 302, an X-direction translation mechanism (blocked and not marked in the figure), and a Y-direction translation mechanism (blocked and not marked in the figure) , sliding base 303, cardboard support seat 304, press frame 305, press lift mechanism 306, upper pressing mechanism 3071, lower pressing mechanism 3081, upper pressing piece 3072, lower pressing piece 3082; x guide rail 301, X direction translation The mechanism (blocked and not marked in the figure) is installed on the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com