A kind of natural rubber briquetting machine

A technology of natural rubber and briquetting machine, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of low efficiency and low degree of automation, and achieve the effect of improving production efficiency and solving the difficulty of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

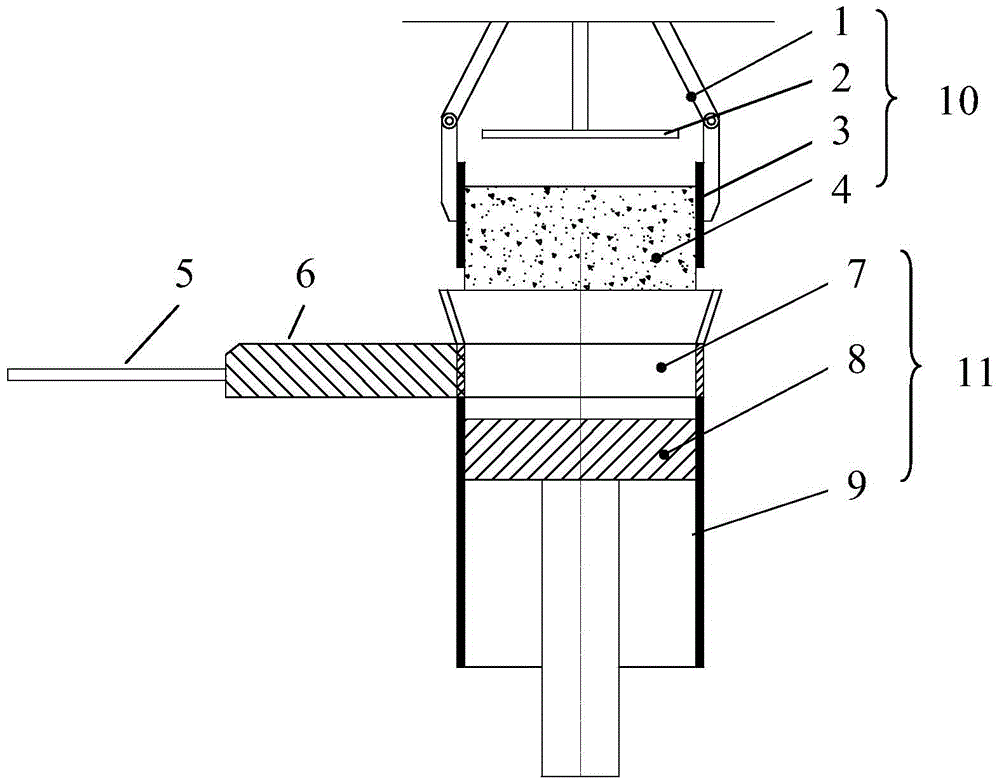

[0029] Such as figure 1 As shown, Embodiment 1 of the present invention provides a kind of natural rubber briquetting machine, and natural rubber block 4 is clamped by the clamping mechanism 1 of mechanical feeding hand 10, and the side of natural rubber block 4 contacts with clamping mechanism 1, contacts Part 3 can be a flat plate or a frame. The mechanical feeding hand 10 moves the natural rubber block to the top of the briquetting machine casing 11 .

[0030] When the mechanical feeding hand 10 moves the natural rubber block to the top of the briquetting machine box body 11, the clamping mechanism 1 of the mechanical feeding hand 10 is released, and at the same time, the pressing mechanism 2 moves downward to contact the natural rubber block 4, and continues to press down. The natural rubber block 4 is pressed into the box body 11, and the clamping mechanism 1 and the pressing mechanism 2 coordinately cooperate to prevent the natural rubber block 4 from tilting during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com