Truck washing tank for construction site

A technology for construction sites and car washing tanks, which is applied in the direction of vehicle external cleaning devices, etc., can solve the problems of easy deformation of steel panels, inconvenient entry and exit of slag trucks, and large load capacity, and achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

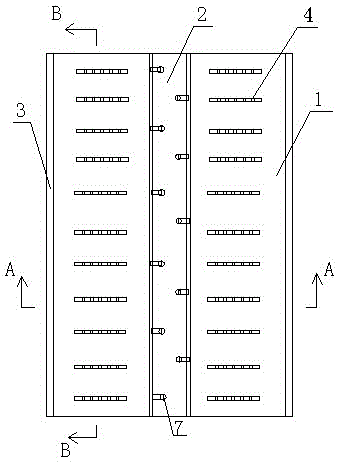

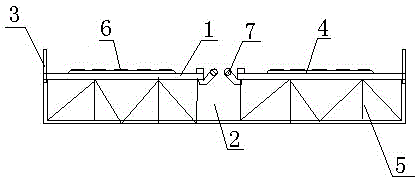

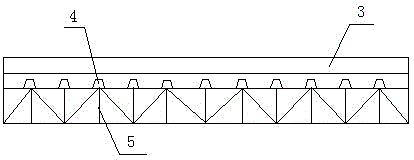

[0022] like figure 1 , figure 2 and image 3 As shown, a car washing tank for a construction site is used for washing off the soil on the vehicle body when the slag truck transports the dregs on the construction site when it enters the road. It includes a vehicle running steel plate 1 and a steel plate Structural base 5, because slag transport vehicles generally have a large load capacity, so the steel structure base 5 generally adopts a herringbone structure and is fixed on the concrete base. The vehicle driving steel plate 1 is arranged on the steel structure base 5. The vehicle weight is large, and the vehicle driving steel plate 1 adopts a flat steel plate with a thickness of about 10 cm. In order to facilitate construction, the vehicle driving steel plate 1 is two pieces, and the two vehicle driving steel plates 1 are welded to form a car washing tank when the vehicle passes through. During the time, a drainage ditch 2 is provided between the two vehicle running steel ...

Embodiment 2

[0025] like figure 1 , figure 2 and image 3 As shown, a car washing tank for a construction site is used for washing off the soil on the vehicle body when the slag truck transports the dregs on the construction site when it enters the road. It includes a vehicle running steel plate 1 and a steel plate Structural base 5, because slag transport vehicles generally have a large load capacity, so the steel structure base 5 generally adopts a herringbone structure and is fixed on the concrete base. The vehicle driving steel plate 1 is arranged on the steel structure base 5. The vehicle weight is large, and the vehicle driving steel plate 1 adopts a flat steel plate with a thickness of about 10 cm. In order to facilitate construction, the vehicle driving steel plate 1 is two pieces, and the two vehicle driving steel plates 1 are welded to form a car washing tank when the vehicle passes through. During the time, a drain ditch 2 is arranged between the two vehicle driving steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com