A treatment device and method for organic silicon waste liquid

A technology of treatment device and treatment method, which is applied in the field of organic silicon industry, and can solve problems such as storage tank corrosion, leakage accidents, tank body expansion and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

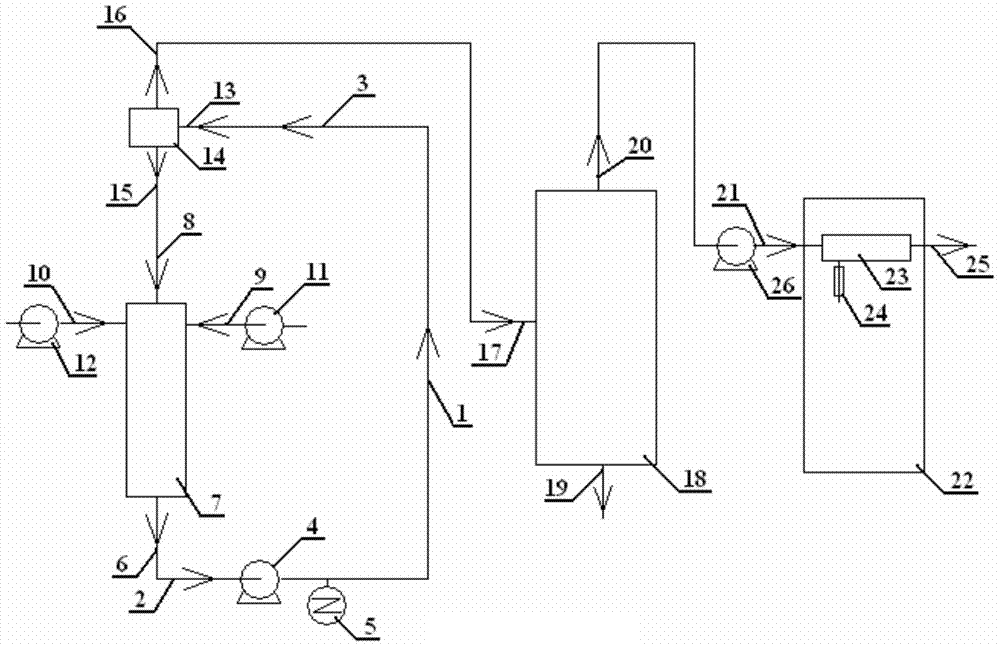

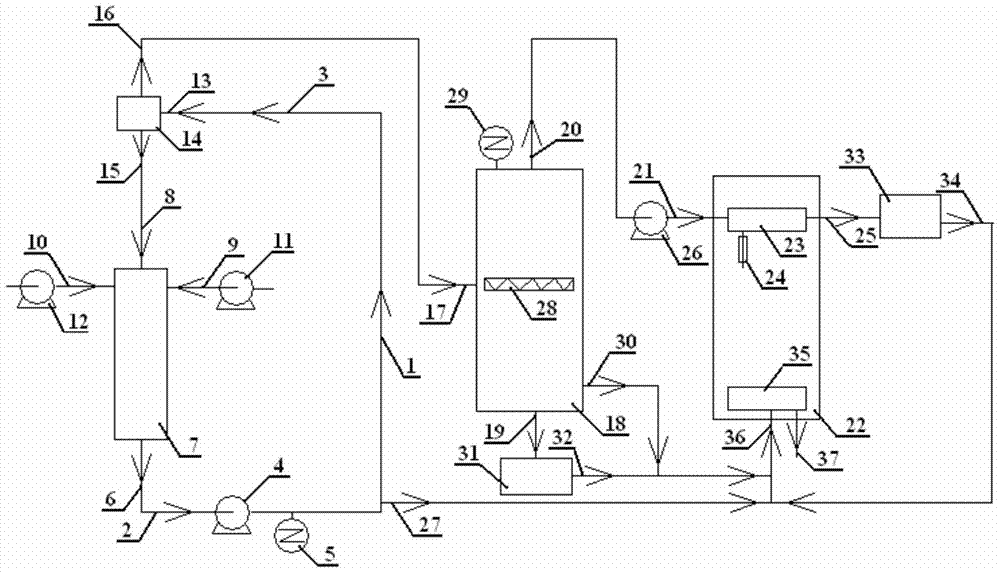

[0075] The structural representation of the treatment device of the organosilicon waste liquid that embodiment 1 provides is as follows figure 2 shown. Among them, 1 is the hydrolysis loop, 2 is the feed port of the hydrolysis loop, 3 is the discharge port of the hydrolysis loop, 4 is the circulation pump, 5 is the cooler, 6 is the discharge port of the static mixer, and 7 is the static mixer, 8 is the inlet of static mixer, 9 is the inlet of water, 10 is the inlet of organic silicon waste liquid, 11-12 is the delivery pump, 13 is the inlet of gravity overflow separator, 14 is the inlet of gravity overflow separator, 15 is The first outlet of the gravity overflow separator, 16 is the second outlet of the gravity overflow separator, 17 is the inlet of the layering device, 18 is the outlet of the layering device, 19 is the outlet of hydrochloric acid, and 20 is the outlet of the layering device 21 is the feed port of the washing device, 22 is the washing device, 23 is the sili...

Embodiment 2

[0089] The treatment device provided in Example 1 is used to treat the organic silicon waste liquid, the organic silicon waste liquid is the organic silicon high boiler cracking raffinate and the organic silicon low boiler with a mass ratio of 8:1, the processing device The working process is as follows:

[0090] (1) Control the feed rate of 0.4t / h through the transfer pump (12) of the organic silicon waste liquid, then continuously enter the static mixer (7) through the organic silicon waste liquid inlet (10), and simultaneously pass the water through the transfer pump (11) Control the water intake to 0.9t / h, and then continuously enter the static mixer (7) through the water inlet (9), after the organic silicon waste liquid and water are mixed in the static mixer (7), The discharge port (6) discharges the static mixer (7);

[0091] (2) The mixture of the organosilicon waste liquid and water discharged from the discharge port (6) enters the hydrolysis loop (1) through the fee...

Embodiment 3

[0098] The treatment device provided in Example 1 is used to treat the organic silicon waste liquid, the organic silicon waste liquid is the organic silicon high boiler cracking raffinate and the organic silicon low boiler with a mass ratio of 5:1, the processing device The working process is as follows:

[0099] (1) Control the feed rate of 0.8t / h through the transfer pump (12) of the organic silicon waste liquid, then continuously enter the static mixer (7) through the organic silicon waste liquid inlet (10), and simultaneously pass the water through the transfer pump (11) Control the water intake to 1.2t / h, and then continuously enter the static mixer (7) through the water inlet (9), after the organic silicon waste liquid and water are mixed in the static mixer (7), The discharge port (6) discharges the static mixer (7);

[0100] (2) The mixture of organic silicon waste liquid and water discharged from the discharge port (6) enters the hydrolysis loop (1) through the feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com