A method for resource utilization of boiler ash flushing water in sugarcane sugar factory

A technology for sugar cane and water resources, which is applied in chemical instruments and methods, purification by physical methods, lime production, etc., can solve problems that do not involve active ash and slag, and achieve green recycling of resources, low cost, and guaranteed sugar production. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

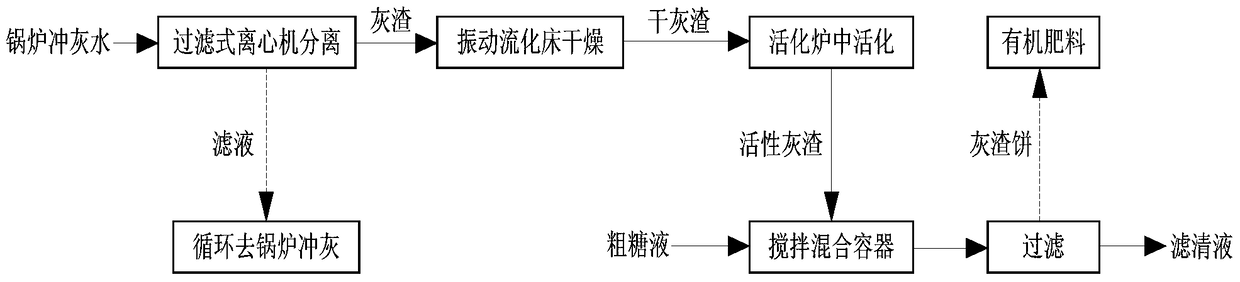

Method used

Image

Examples

Embodiment 1

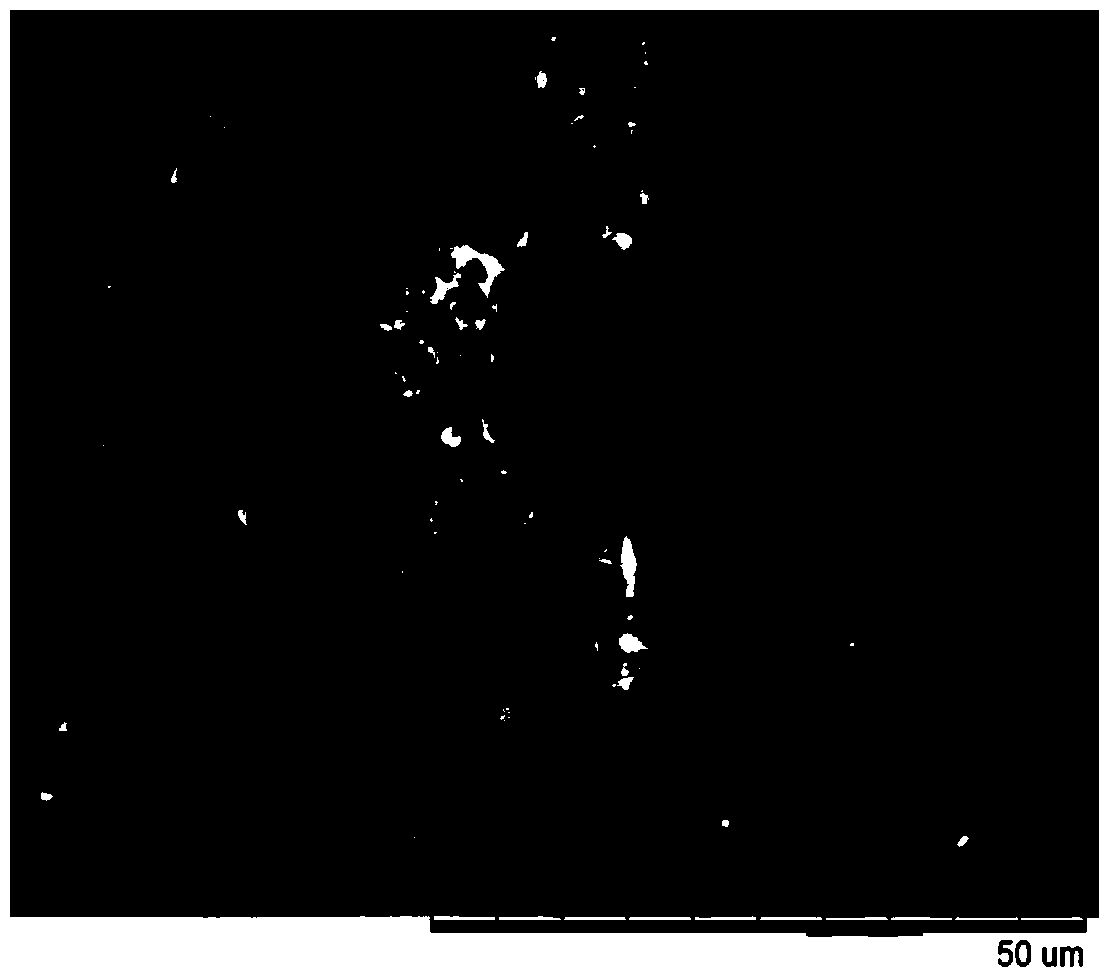

[0021] Take 1.0m 3 The solid-liquid mixed sugarcane sugar factory boiler ash flushing water is separated by a filter-type continuous centrifuge with a screen aperture of 12,500 meshes to obtain filtrate and ash. The filtrate is recycled to the boiler for ash flushing. Fluidized bed drying, the dry ash obtained after drying has a water content of 19±1%; the obtained dry ash is put into an activation furnace, and under the conditions of a microwave power of 200W and a reaction temperature of 800°C, water vapor is used as an activator Activate for 10 minutes to obtain active ash, which is detected by a focused beam reflectometer (FBRM). The crude sugar solution treated by floating technology is mixed according to the mass ratio of 1:10, stirred for 55 minutes under the condition that the temperature of the mixed solution is 50°C and the pH value is adjusted by adding milk of lime to 7.5, and then filtered, and the filtrated clear liquid is collected, and the retained adsorption c...

Embodiment 2

[0023] Take 1.0m 3 The ash water from the boiler of the sugarcane sugar factory mixed with solid and liquid is separated by a filter-type continuous centrifuge with a screen aperture of 800 meshes to obtain filtrate and ash. Vibrating fluidized bed drying, the dry ash obtained after drying has a water content of 15±1%; put the obtained dry ash into an activation furnace, and activate it with water vapor under the conditions of a microwave power of 600W and a reaction temperature of 900°C The active ash was activated for 60min to obtain the active ash, which was detected by a focused beam reflectance measuring instrument (FBRM), and the main distribution range was 1-1000 μm; Mix at a mass ratio of 1:2000, stir for 15 minutes under the condition that the temperature of the mixed solution is 95° C. and add milk of lime to adjust the pH to 7.0, filter, collect the filtrated clear liquid, and the retained adsorption contains 11% organic matter by mass fraction (the main component i...

Embodiment 3

[0025] Take 1.0m 3 The ash water from the boiler of the sugarcane sugar factory mixed with solid and liquid is separated by a filter-type continuous centrifuge with a screen aperture of 250 meshes to obtain filtrate and ash. Vibrating fluidized bed drying, the water content of the dry ash obtained after drying is less than or equal to 20%; put the obtained dry ash into the activation furnace, and use carbon dioxide as the activation furnace under the conditions of microwave power of 900W and reaction temperature of 950°C The active ash was activated for 300min to obtain the active ash, which was detected by a focused beam reflectance measuring instrument (FBRM), and the main distribution range was 1-1000 μm; Mix at a mass ratio of 1:200, stir for 25 minutes under the condition that the temperature of the mixed solution is 65° C. and add milk of lime to adjust the pH to 7.2, filter, collect the filtered clear liquid, and the retained adsorption contains 11.5% organic matter by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com