Furnace roller installation device and furnace roller installation method

A technology of installation device and installation location, which is applied in the direction of furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of furnace roller site restrictions, roller surface damage, etc., and achieve the effects of reducing installation difficulty, ensuring installation quality, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

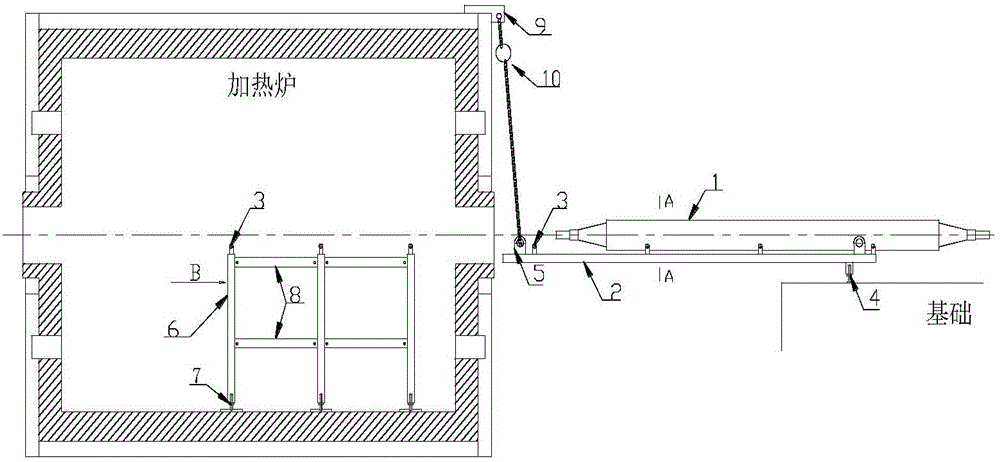

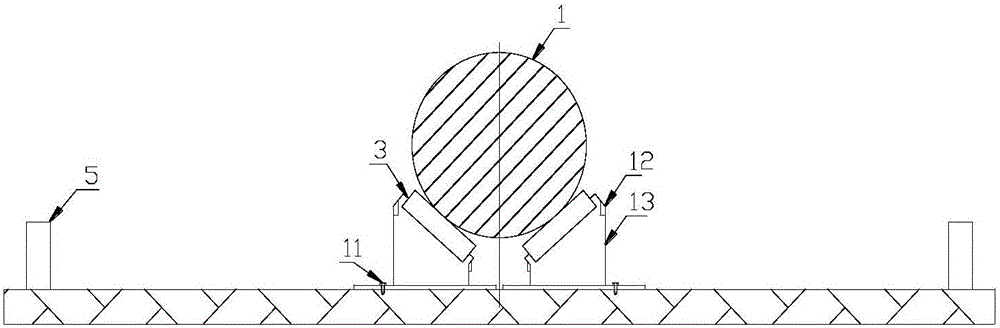

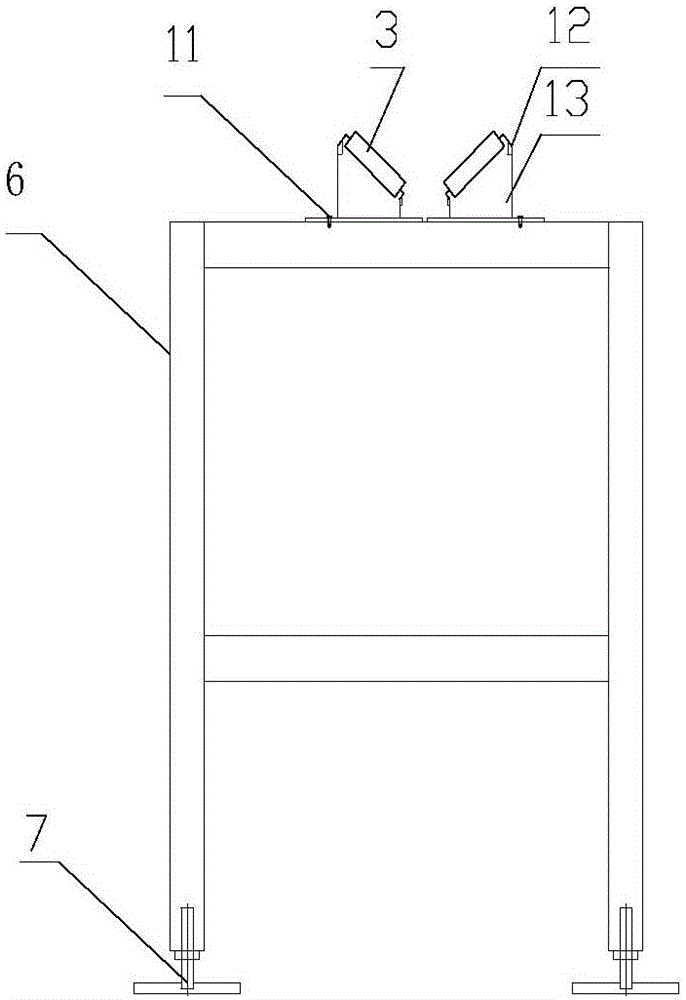

[0024] refer to Figure 1 ~ Figure 3 As shown, a furnace roller installation device includes a platform bottom plate 2, a roller bracket, and roller components. The platform bottom plate 2 is arranged on the transmission side of the installation position of the furnace roller 1 outside the furnace, and the roller bracket is arranged inside the furnace. ; The roller parts are arranged on the platform floor 2 outside the furnace and the roller bracket in the furnace;

[0025] The platform bottom plate 2 includes a platform bottom plate 2, and a plurality of idler parts located on the platform bottom plate 2 are arranged along the center line of the platform bottom plate 2, and the bottom of the idler parts is connected with the platform bottom plate 2 through fixing bolts 11, and the bottom of the front end of the platform bottom plate 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com