Main cable strand dispersing structure for suspension bridge

A technology for suspension bridges and main cables, applied in the direction of suspension bridges, bridges, bridge parts, etc., can solve the problems of small-scale main cables, difficulty in precise positioning, low economic benefits, etc. The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

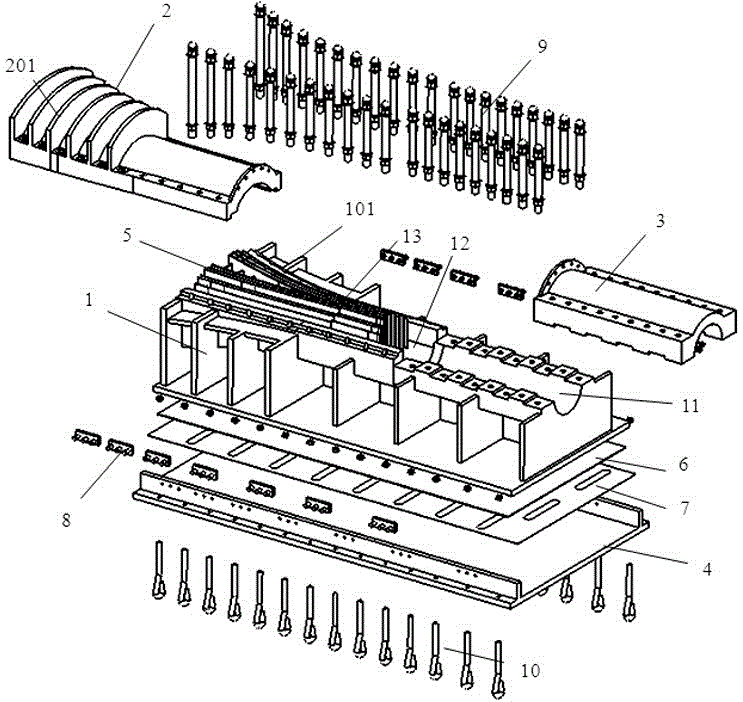

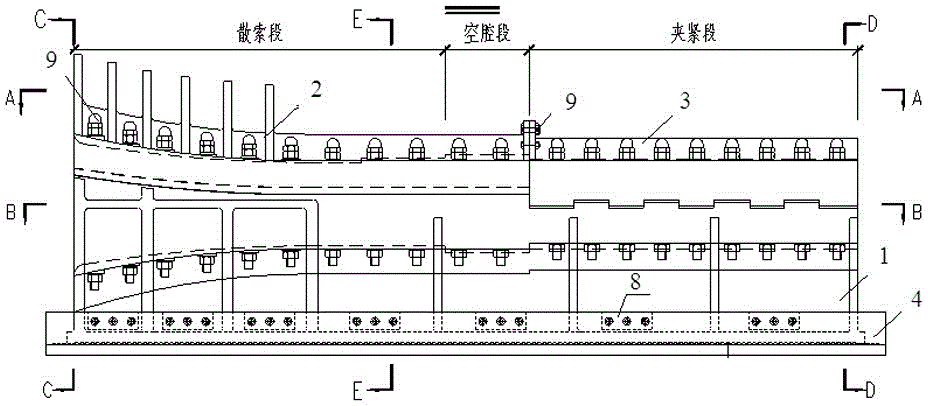

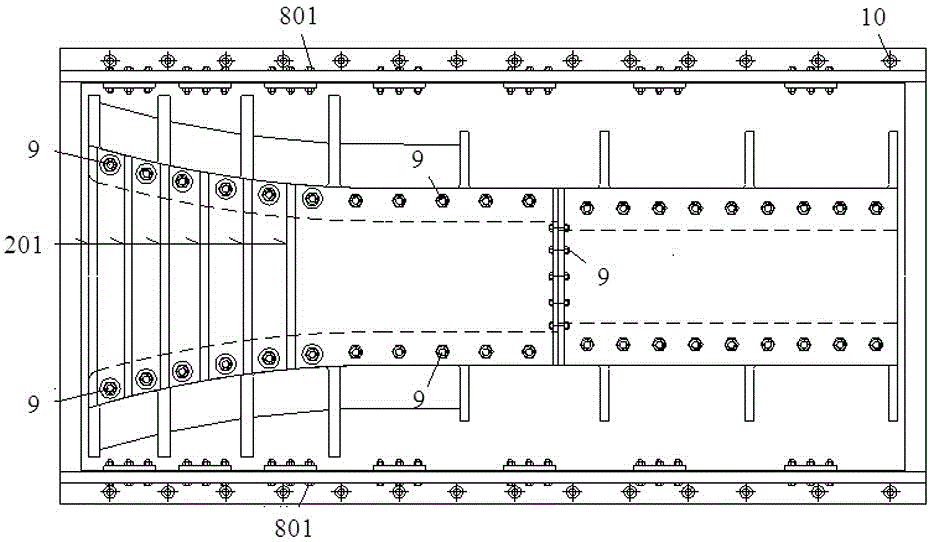

[0029] based on the following Figure 1 to Figure 9 , specifically describe the preferred embodiment of the present invention.

[0030] Such as Figure 1 to Figure 7 As shown, the present invention provides a main cable scatter cable structure for a suspension bridge, comprising:

[0031] The lower saddle body 1, the lower saddle body 1 includes a front saddle body 11, a middle saddle body 12 and a rear saddle body 13, and the rear saddle body 13 has several guide grooves (not shown in the figure), The guide groove is arc-shaped, and the arc length of the guide groove needs to ensure that the tangent point of the main cable strand is within the arc;

[0032] Several partitions 5, which are arranged in the guide groove, are used to separate the main cable strands; the thickness of the partitions 5 near the exit of the lower saddle body 1 is greater than the thickness of the rest of the partitions, so that the partitions 5 Near the exit of the lower saddle body 1, a flat curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com