Steel tube and core tube mixed structure

A hybrid structure and core tube technology, applied in building construction, construction, etc., can solve the problems of reduced lateral stiffness, ductility and energy dissipation capacity of the structure, increased construction difficulty and cost, unsuitable welding quality guarantee, etc., and achieves hysteresis. The effect of full curve, high bearing capacity and high initial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

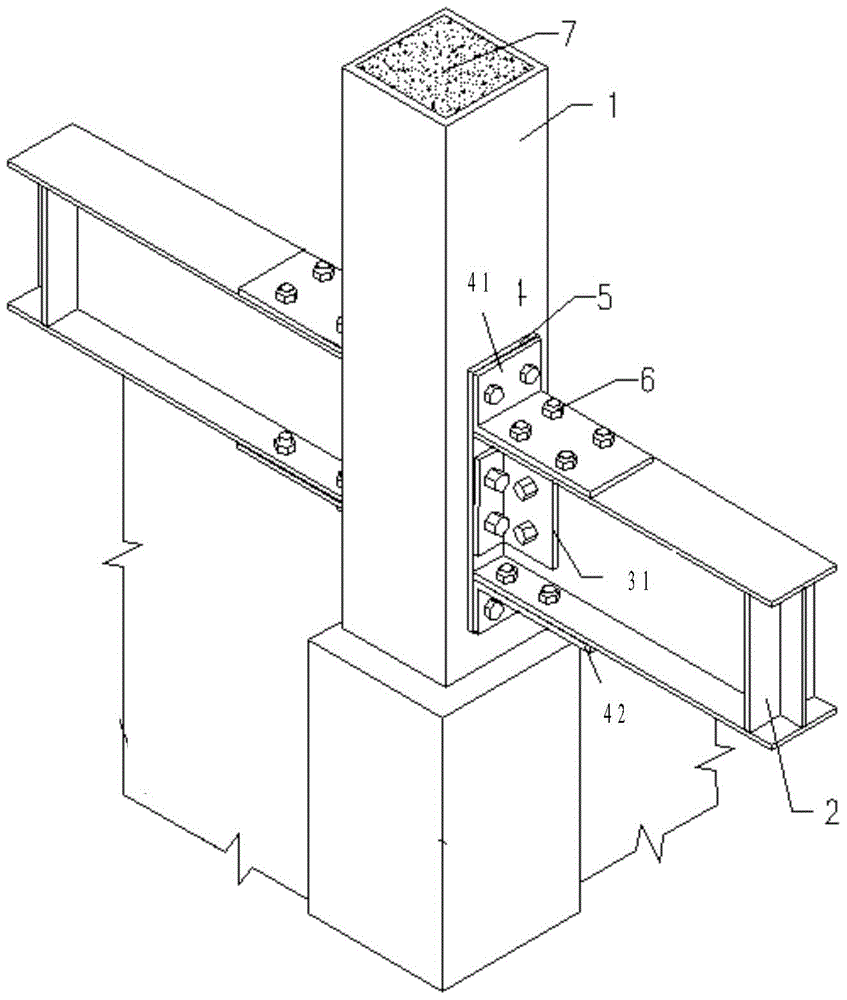

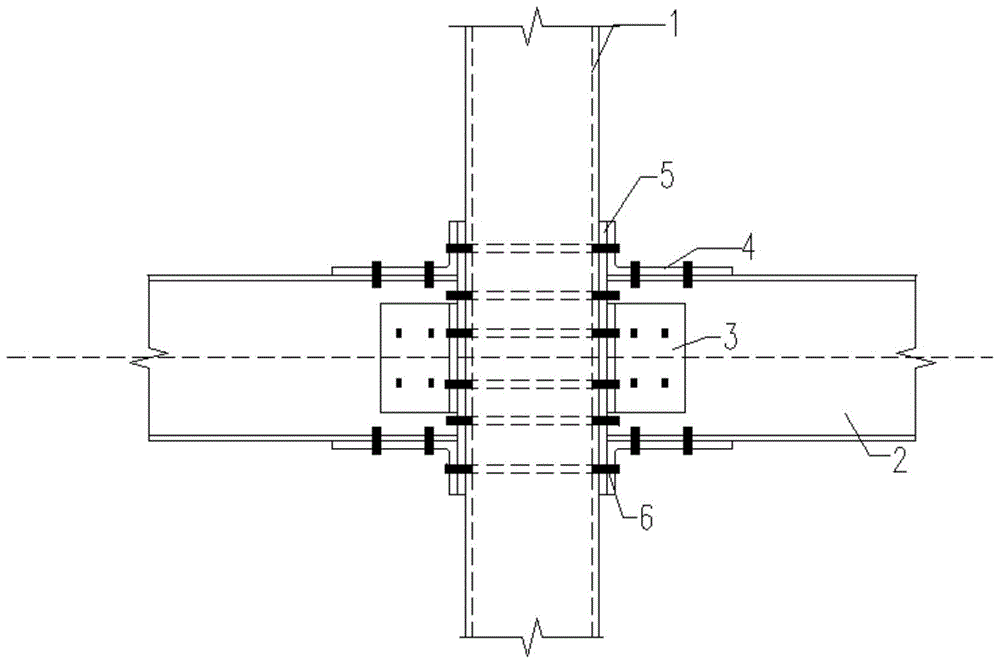

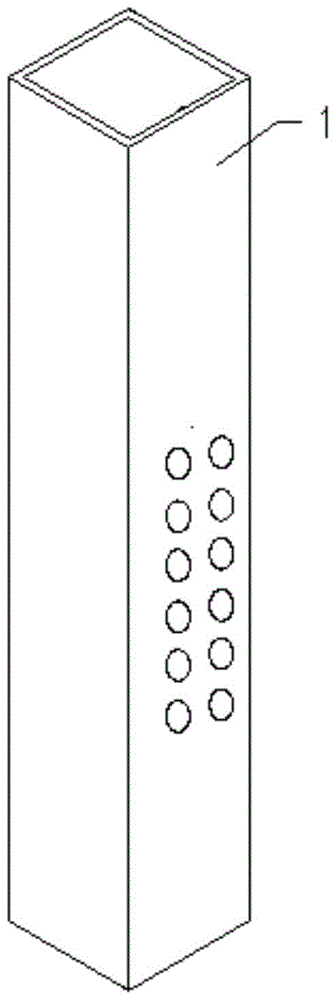

[0019] Such as Figure 1 to Figure 4 The steel pipe core tube hybrid structure shown includes steel columns 1, steel beams 2, two equilateral angle steels 3, two unequal angle steels 4, overhanging end plates 5, high-strength bolts 6, and concrete 7, in which:

[0020] The steel column 1 is a steel pipe, and the flange of the steel column 1 has 8 bolt holes; the steel beam 2 is an H-shaped steel, including the upper and lower flanges and the web in the middle, and the upper and lower flanges at the proximal end of the steel beam 2 are respectively opened. There are 4 bolt holes; the overhanging end plate 5 has 8 bolt holes; the two unequal angle steels 4 are the top angle steel 41 and the bottom angle steel 42 respectively, and the top angle steel 41 and the bottom angle steel 42 are connected with the overhanging end plate 5 Two holes are opened on the side, and four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com